Introduction

In industries where material purity and performance are non-negotiable—like aerospace, medical implants, and nuclear energy—Vacuum Induction Melting (VIM) has emerged as the gold standard. This article breaks down why VIM outperforms traditional melting methods, delivering alloys with unmatched structural integrity and longevity. By examining its electromagnetic precision, vacuum-driven impurity control, and real-world applications, you’ll discover how VIM reduces long-term costs while elevating product quality.

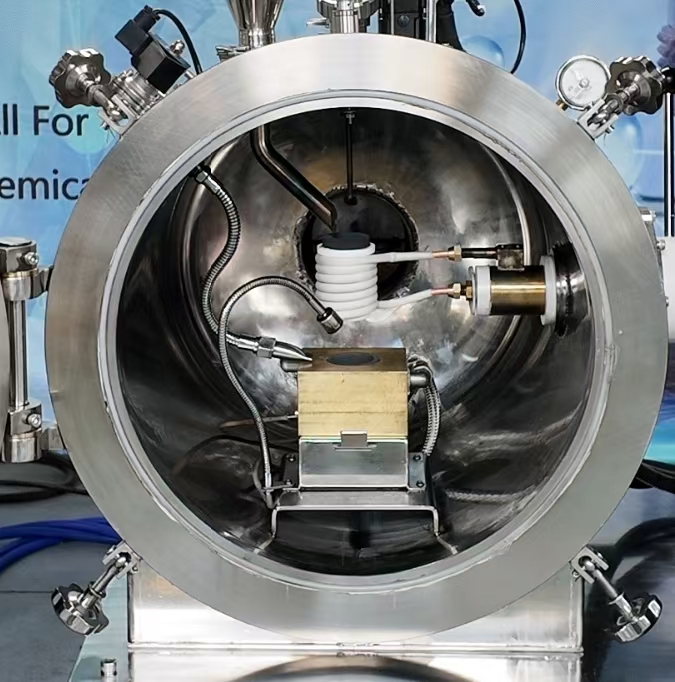

Vacuum Induction Melting Fundamentals

Electromagnetic Principles and Quality Assurance

VIM uses electromagnetic induction to melt metals under vacuum conditions, eliminating contamination from crucibles or external gases. The process ensures:

- Homogeneous mixing of alloying elements (e.g., nickel, titanium)

- Minimal carbon pickup (critical for aerospace-grade superalloys)

- Repeatable batch consistency, reducing post-production testing costs

Ever wondered how turbine blades withstand extreme temperatures? VIM’s precise temperature control prevents segregation defects that weaken alloys.

Vacuum Technology’s Role in Impurity Elimination

The vacuum environment (10⁻³ to 10⁻⁶ mbar) removes dissolved gases (oxygen, nitrogen) and volatile impurities (lead, bismuth). For context:

- Medical implants: VIM reduces oxidation, ensuring biocompatibility.

- Nuclear components: Low hydrogen levels prevent embrittlement.

Think of VIM as a "high-stakes filter"—it strips away flaws at the atomic level.

Industry-Specific Applications and Outcomes

Aerospace: Turbine Blade Durability Enhancements

Jet engines demand alloys that resist creep and thermal fatigue. VIM-produced superalloys (e.g., Inconel 718) show:

- 30% longer service life compared to arc-melted equivalents

- Fewer grain boundary defects, crucial for FAA compliance

Medical: Oxidation-Free Implant Manufacturing

Titanium implants melted via VIM exhibit:

- Near-zero porosity, reducing bacterial adhesion risks

- Enhanced osseointegration due to controlled oxygen content

Energy: Corrosion-Resistant Nuclear Components

VIM-processed zirconium alloys for reactor cladding:

- Withstand radiation-induced swelling

- Reduce maintenance downtime by 40%

Cost-Benefit Analysis for Manufacturers

Upfront Costs vs. Long-Term Quality Improvements

While VIM requires higher initial investment (equipment, vacuum systems), it slashes costs through:

- Lower scrap rates (5% vs. 15% in arc melting)

- Reduced post-machining (thanks to near-net-shape casting)

Comparative Metrics: VIM vs. Arc Melting

| Metric | VIM | Arc Melting |

|---|---|---|

| Oxygen Content (ppm) | <50 | 200–500 |

| Production Yield | 92–95% | 80–85% |

| Energy Efficiency | 15% higher | Baseline |

Conclusion and Actionable Insights

VIM isn’t just a melting method—it’s a strategic upgrade for manufacturers prioritizing reliability and total cost of ownership. For labs and foundries, integrating VIM-ready equipment (like Kintek’s vacuum systems) future-proofs production lines against quality failures.

Next Steps:

- Audit current alloy defect rates to quantify VIM’s potential ROI.

- Explore modular VIM systems for pilot-scale testing before full adoption.

Products You Might Be Looking For:

https://kindle-tech.com/products/vacuum-induction-melting-furnace

https://kindle-tech.com/products/molybdenum-vacuum-furnace

https://kindle-tech.com/products/2200-graphite-vacuum-furnace

https://kindle-tech.com/products/vacuum-pressure-sintering-furnace

https://kindle-tech.com/products/vacuum-pressure-sintering-furnace

https://kindle-tech.com/products/600t-vacuum-induction-hot-press-furnace

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

Related Articles

- Molybdenum Vacuum Furnace: High-Temperature Sintering and Heat Treatment

- How Vacuum Induction Melting Ensures Unmatched Reliability in Critical Industries

- Molybdenum Vacuum Furnace: High-Temperature Sintering and Advanced Applications

- The Art of Absence: Why Advanced Materials Demand Vacuum Furnaces

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.