Yes, hydrogen can be produced from biomass, and it is considered a promising pathway for sustainable energy. The most established method is biomass gasification, a thermochemical process that converts organic materials like wood, agricultural waste, or dedicated energy crops into a hydrogen-rich gas. This approach is valued for its potential to create low-carbon hydrogen from a renewable and abundant resource.

While the science of converting biomass to hydrogen is well-proven, significant techno-economic barriers currently prevent its large-scale deployment. The core challenge lies in making the process efficient and cost-competitive with traditional hydrogen production methods.

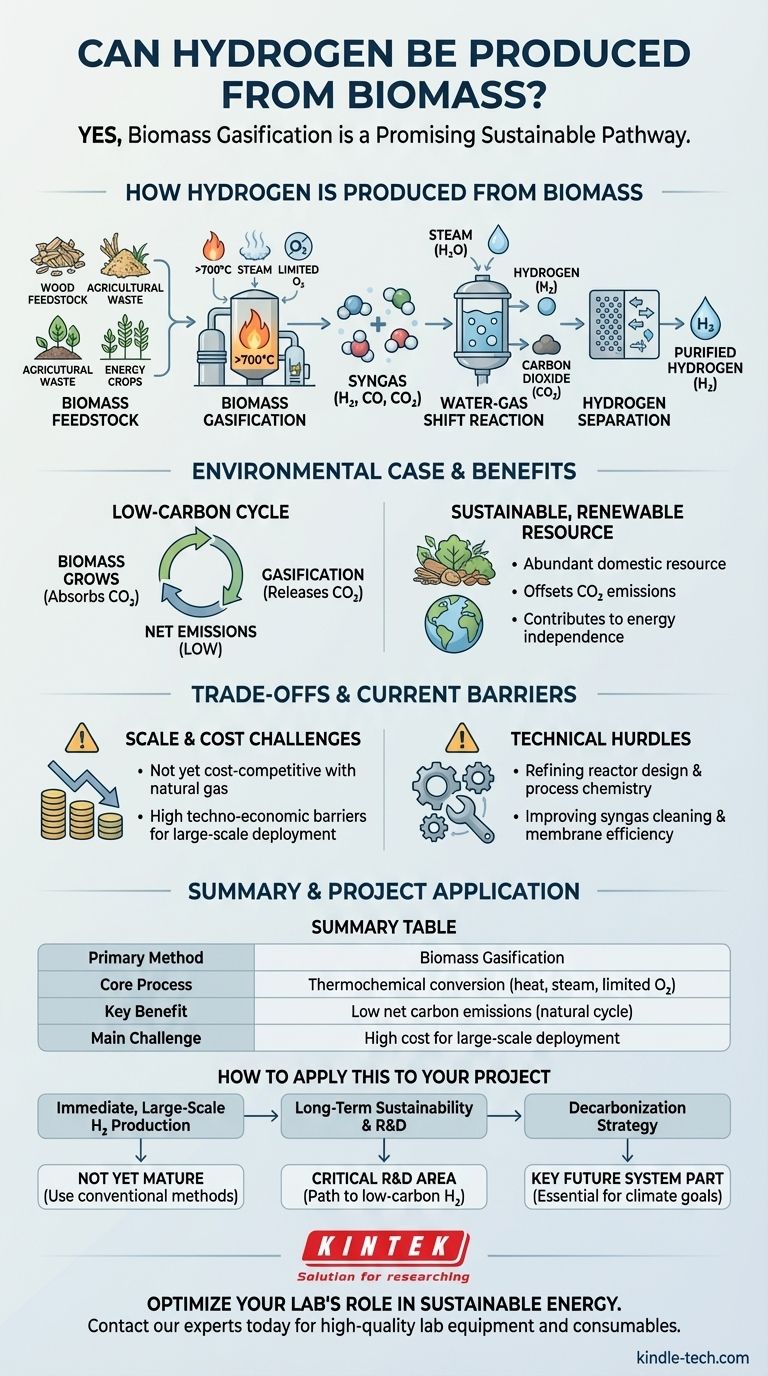

How Hydrogen is Produced from Biomass

The conversion process is a multi-step thermal and chemical operation designed to break down complex organic matter and extract hydrogen gas.

The Core Process: Gasification

The primary method is biomass gasification. This is not combustion or burning; it is a controlled process that uses high temperatures (over 700°C), steam, and a limited amount of oxygen.

This environment breaks down the biomass into a mixture of gases known as synthesis gas, or "syngas." This gas is primarily composed of hydrogen, carbon monoxide, and carbon dioxide.

Maximizing Hydrogen Yield: The Water-Gas Shift Reaction

To increase the amount of hydrogen, the syngas is put through a secondary process called the water-gas shift reaction.

In this stage, the carbon monoxide (CO) from the syngas reacts with water (H₂O) in the form of steam. This chemical reaction produces more hydrogen (H₂) and additional carbon dioxide (CO₂).

Isolating the Final Product: Hydrogen Separation

The final gas stream contains a high concentration of hydrogen but also includes carbon dioxide and other impurities.

To get pure hydrogen, this mixed gas is passed through specialized membranes or pressure swing adsorbers. These systems selectively separate the hydrogen molecules from the rest of the gas stream, resulting in a purified final product.

The Environmental Case for Biomass-to-Hydrogen

The interest in using biomass is driven almost entirely by its environmental benefits compared to fossil fuels.

A Low-Carbon Cycle

Using biomass for hydrogen production results in low net greenhouse gas emissions. This is because the process is part of a natural carbon cycle.

As the biomass (plants) grows, it absorbs carbon dioxide from the atmosphere. This absorption effectively offsets the CO₂ released when the biomass is converted into hydrogen.

A Sustainable, Renewable Resource

Unlike finite fossil fuels, biomass is a renewable resource. In many regions, such as the United States, there is more biomass available than is required for food and animal feed needs.

This abundance makes it a sustainable domestic resource that can contribute to energy independence and a more resilient energy infrastructure.

Understanding the Trade-offs and Current Barriers

Despite its clear potential, biomass-to-hydrogen technology is not yet ready for widespread commercial use. Several key challenges must be overcome.

The Challenge of Scale and Cost

The most significant barrier is economic. Currently, producing hydrogen from biomass is not cost-competitive with established methods like natural gas reforming.

These "techno-economic barriers" mean that while the technology works in a lab or pilot setting, it is not yet reliable or affordable enough for large-scale industrial deployment.

Technical Hurdles in the Process

Further development is needed to refine the technology itself. This includes improving reactor design, optimizing the process chemistry, and developing more efficient methods for cleaning and conditioning the syngas.

Innovations in areas like new membrane technologies are also needed to reduce the cost of separating gases, a critical step in both providing oxygen for gasification and purifying the final hydrogen product.

How to Apply This to Your Project

Understanding the state of this technology is key to making strategic decisions about its role in any energy portfolio.

- If your primary focus is immediate, large-scale hydrogen production: This technology is not yet mature enough; conventional methods based on natural gas remain the dominant, cost-effective choice for now.

- If your primary focus is long-term sustainability and R&D investment: Biomass-to-hydrogen is a critical area for research, offering a path to low-carbon hydrogen from a renewable feedstock.

- If your primary focus is decarbonization strategy: This pathway should be considered a key part of future energy systems, as its low net-emission profile is essential for meeting climate goals.

Ultimately, producing hydrogen from biomass represents a vital frontier where scientific potential is actively working to overcome economic realities.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Method | Biomass Gasification |

| Core Process | Thermochemical conversion using heat, steam, and limited oxygen |

| Key Benefit | Low net carbon emissions (part of natural carbon cycle) |

| Main Challenge | High cost and techno-economic barriers for large-scale deployment |

| Current Status | Proven technology, but not yet cost-competitive with fossil fuel methods |

Optimize Your Lab's Role in the Future of Sustainable Energy

Are you researching biomass conversion, hydrogen purification, or reactor design? KINTEK specializes in providing the high-quality lab equipment and consumables you need to advance this critical field. From gas analysis to process optimization, our reliable tools help you overcome the technical hurdles in biomass-to-hydrogen technology.

Contact our experts today to discuss how our solutions can support your R&D and help build a sustainable energy future.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- Why is a high-precision heat treatment furnace necessary for maraging steel? Ensure Peak SLM Part Performance

- What role does a precision temperature-controlled furnace play in the PWHT of P91/Incoloy 800HT joints? Achieve Integrity

- Is brazing and soldering the same? Understand the Critical Temperature Difference for Stronger Joints

- What is VAR in metallurgy? Achieve Superior Metal Purity and Performance

- What function does the vacuum environment serve during the densification of Ag-SnO2-Y2O3? Optimize Material Density

- What does sintering do to metal? Transform Powder into Durable, High-Performance Parts

- What is the function of a vacuum drying oven for PEO processing? Key to High-Performance Solid-State Electrolytes

- What are the disadvantages of heat treatment? Managing the Risks of Distortion and Cost