Yes, you can absolutely make flour with a hammer mill. A hammer mill is a type of impact mill that pulverizes material, and it is frequently used to grind grains like corn, wheat, and oats into a meal or coarse flour. The final texture is determined by the screen size installed in the machine.

The core issue isn't whether a hammer mill can make flour, but understanding the type of flour it produces. It excels at creating coarse, whole-grain flours or animal feed through brute-force impact, which is a fundamentally different process than the shearing or grinding action of traditional flour mills.

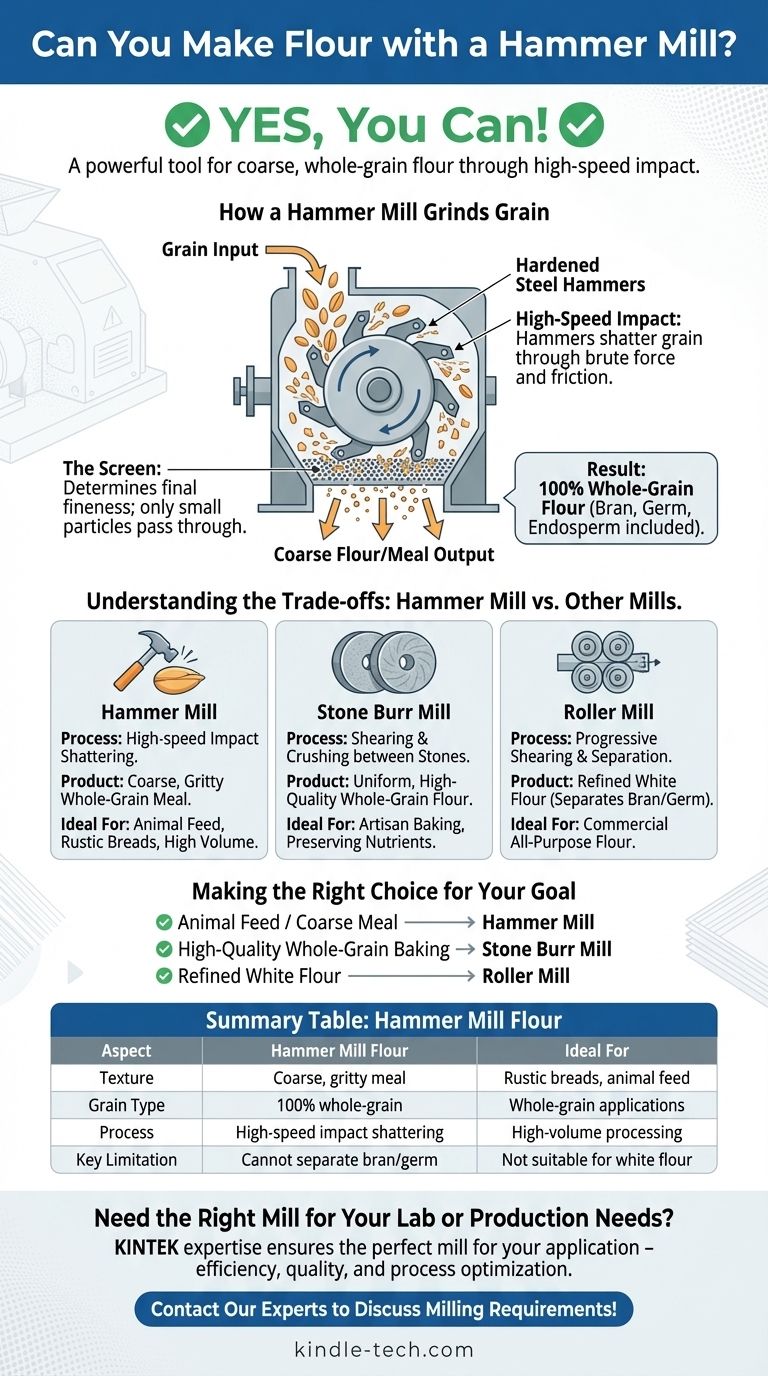

How a Hammer Mill Grinds Grain

A hammer mill doesn’t cut or shear grain in the way other mills do. Its mechanism is based entirely on high-speed impact, which has specific consequences for the final product.

The Role of High-Speed Impact

A hammer mill contains a series of hardened steel hammers that rotate at very high speeds inside a grinding chamber. When grain is fed into the mill, these hammers shatter it on impact.

This process is aggressive and generates a significant amount of heat due to friction and the energy of the impacts.

The Critical Function of the Screen

The grinding chamber is lined with a perforated screen. Pulverized material is thrown against this screen, and only particles small enough to pass through its holes can exit the mill.

The size of the holes in the screen is the primary factor that determines the final fineness of the flour or meal. To produce finer flour, you must use a screen with smaller perforations.

The Result: A Coarse, Whole-Grain Flour

Because the entire grain kernel—bran, germ, and endosperm—is shattered together, a hammer mill inherently produces 100% whole-grain flour. There is no mechanism for sifting or separating these components during the milling process.

Understanding the Trade-offs: Hammer Mill vs. Other Mills

The choice of a mill depends entirely on your intended use for the flour. The brute-force action of a hammer mill creates a product with distinct characteristics compared to flour from more specialized mills.

vs. Stone Burr Mills

Stone mills grind grain between two heavy stone wheels, shearing the bran and crushing the endosperm. This process creates a more uniform particle size with less heat generation, which is often preferred for high-quality, whole-grain baking flours as it better preserves the grain's natural oils and nutrients.

vs. Roller Mills

Roller mills are the industrial standard for producing refined white flour. They use a series of steel rollers to progressively shear open the grain, scraping the endosperm away from the bran and germ. This separation is something a hammer mill simply cannot do.

The Primary Advantage of a Hammer Mill

The key strength of a hammer mill is its versatility and high throughput. It can process a wide variety of materials beyond grain, including tough, fibrous plant matter, making it an excellent choice for producing animal feed or materials for biofuels. It is a workhorse designed for volume, not finesse.

Making the Right Choice for Your Goal

Selecting the right mill requires matching the tool to the task. The flour from a hammer mill is perfectly suitable for some applications but not for others.

- If your primary focus is producing animal feed or a coarse meal for rustic breads: A hammer mill is an excellent, efficient, and cost-effective choice.

- If your primary focus is creating high-quality, whole-grain flour for baking: A stone burr mill will provide a more uniform texture and better preserve the nutritional integrity of the grain.

- If your primary focus is producing refined white (all-purpose) flour: Neither a hammer mill nor a stone mill is the right tool; this requires a roller mill.

Ultimately, a hammer mill is a powerful tool for size reduction, perfectly capable of turning whole grains into flour for specific applications.

Summary Table:

| Aspect | Hammer Mill Flour | Ideal For |

|---|---|---|

| Texture | Coarse, gritty meal | Rustic breads, animal feed |

| Grain Type | 100% whole-grain (bran, germ, endosperm) | Whole-grain applications |

| Process | High-speed impact shattering | High-volume processing |

| Key Limitation | Cannot separate bran/germ for refined flour | Not suitable for white/all-purpose flour |

Need the Right Mill for Your Lab or Production Needs?

Choosing the correct milling equipment is critical for achieving your desired product quality and consistency. Whether you require the high-volume, versatile grinding of a hammer mill for feed and coarse materials, or the fine, controlled milling of other equipment for baking and research, KINTEK has the expertise and solution for you.

As a specialist in lab equipment and consumables, KINTEK can help you select the perfect mill to match your specific application—ensuring efficiency, preserving nutritional value, and optimizing your process.

Contact our experts today to discuss your milling requirements and find the ideal equipment for your laboratory or production facility!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the benefit of using tungsten carbide (WC) milling jars and balls? Achieve High-Energy Milling Efficiency

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results

- Why are zirconia (ZrO2) milling jars recommended for sulfide electrolytes? Ensure Purity in Li6PS5Cl Synthesis

- Why use zirconia ball milling jars for SiC/ZTA composite powders? Ensure High Purity & Efficient Particle Refinement

- Why is a ball mill jar lined with Y-ZrO2 required for Na3PS4 synthesis? Ensuring Purity in Sulfide Electrolytes