To be direct, the answer is not a simple yes or no. Whether a biofuel damages the environment depends entirely on its source material and the methods used for its production and refinement. While some biofuels offer a clear reduction in lifecycle carbon emissions compared to fossil fuels, others can be significantly more harmful to the climate, land, and water resources.

The central challenge with biofuels is that their "green" reputation is often undermined by the environmental costs of their production. The promise of carbon neutrality at the tailpipe can be completely erased by the reality of land use changes, water consumption, and fertilizer runoff required to grow the source crops.

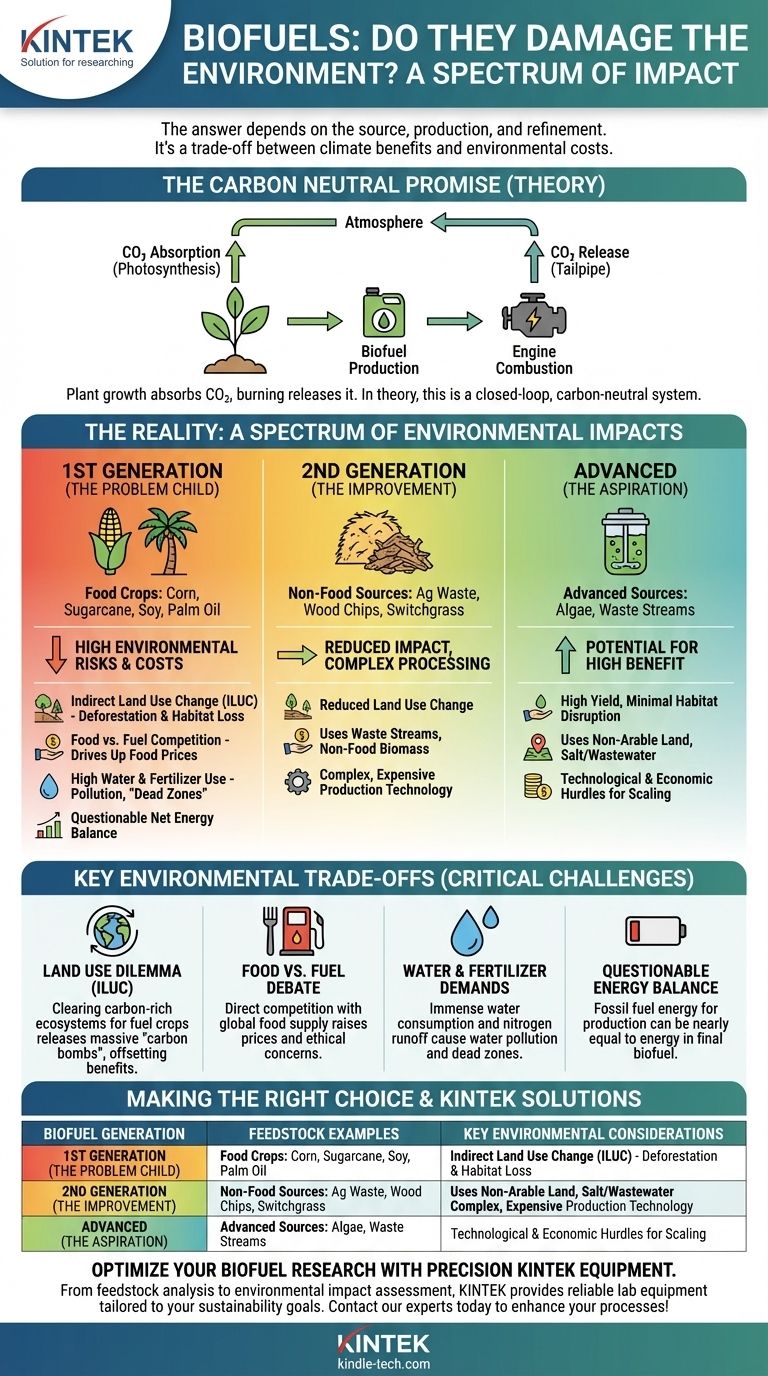

The Carbon Neutral Promise of Biofuels

The core appeal of biofuels is rooted in a simple idea: the carbon cycle.

The Basic Principle

Plants absorb carbon dioxide (CO2) from the atmosphere as they grow. When that plant matter (biomass) is converted into fuel and burned, it releases that same CO2 back into the atmosphere.

In theory, this creates a closed-loop system. The CO2 released is equal to the CO2 absorbed, making the fuel "carbon neutral" and not contributing new greenhouse gases to the atmosphere, unlike fossil fuels which release ancient, trapped carbon.

The Reality: A Spectrum of Environmental Impacts

This theoretical carbon neutrality breaks down when we examine the full lifecycle of producing the fuel. Biofuels are typically categorized into "generations," each with a vastly different environmental footprint.

First-Generation Biofuels (The Problem Child)

These fuels are derived directly from food crops. The most common examples are corn ethanol (prevalent in the U.S.) and sugarcane ethanol (Brazil), as well as biodiesel from soy and palm oil.

These are the most controversial and often the most damaging. Their production is directly linked to major environmental and ethical problems.

Second-Generation Biofuels (The Improvement)

Also known as cellulosic biofuels, these are produced from non-food sources. This includes agricultural waste (corn stalks, wheat straw), wood chips, or dedicated non-food energy crops like switchgrass.

By using waste products or crops grown on marginal land unsuitable for food production, these fuels begin to solve many of the problems associated with the first generation. However, the technology to break down tough cellulosic material is more complex and expensive.

Advanced Biofuels (The Aspiration)

This category includes third- and fourth-generation biofuels, which represent a significant technological leap. The most prominent example is fuel derived from algae.

Algae can be grown in ponds or bioreactors on non-arable land, can use saltwater or wastewater, and grow much faster than land crops. They have the potential to produce vastly more fuel per acre with a fraction of the environmental impact, though scaling the technology remains a significant economic and engineering hurdle.

Understanding the Critical Trade-offs

The debate over biofuels hinges on a few key environmental and economic trade-offs that are most severe with first-generation fuels.

The Land Use Dilemma (ILUC)

The most significant hidden cost is Indirect Land Use Change (ILUC). When existing cropland is diverted from growing food to growing fuel, that food must be grown somewhere else.

This often forces agricultural expansion into new areas, frequently by clearing carbon-rich ecosystems like forests, peatlands, or grasslands.

This act of land conversion can release a massive, one-time "carbon bomb" that can take decades, or even centuries, for the biofuel's "carbon savings" to pay back. For this reason, palm oil and soy biodiesel are often considered worse for the climate than conventional diesel.

The Food vs. Fuel Debate

Using staple food crops like corn and soy to produce fuel creates direct competition with the global food supply.

This competition can drive up food prices, disproportionately affecting the world's poorest populations. It represents a significant ethical dilemma in using agricultural capacity for energy instead of nutrition.

Water and Fertilizer Demands

Growing crops for fuel at an industrial scale requires immense quantities of water and nitrogen fertilizer.

Corn, in particular, is a notoriously thirsty crop. Runoff from nitrogen fertilizers is a primary cause of water pollution and creates "dead zones" in coastal areas like the Gulf of Mexico.

Questionable Energy Balance

For some first-generation biofuels, especially corn ethanol, the Net Energy Balance is worryingly low. This means the amount of fossil fuel energy required to plant, fertilize, harvest, transport, and refine the corn is nearly as much as the energy contained in the final ethanol product.

If the net energy gain is minimal, the primary function of the biofuel program becomes subsidizing agriculture rather than providing a meaningful climate solution.

Making the Right Choice for Your Goal

The term "biofuel" is too broad to be useful without qualification. Your assessment must be specific to the feedstock and production pathway.

- If your primary focus is immediate, verifiable climate benefit: Prioritize second- and third-generation biofuels made from waste streams (e.g., used cooking oil, agricultural residue) or algae. Be highly skeptical of any fuel derived from food crops grown on dedicated land.

- If your primary focus is energy security and diversification: Acknowledge that first-generation biofuels can reduce reliance on foreign oil but insist on a clear policy roadmap to phase them out in favor of advanced biofuels that don't compete with food or destroy habitats.

- If your primary focus is long-term sustainability: View biofuels not as a singular solution, but as a potential niche player within a larger portfolio of renewable energy sources, including electrification, green hydrogen, and synthetic fuels.

Ultimately, evaluating any biofuel requires looking beyond the tailpipe to its entire journey from seed to engine.

Summary Table:

| Biofuel Generation | Feedstock Examples | Key Environmental Considerations |

|---|---|---|

| First-Generation | Corn, Sugarcane, Soy, Palm Oil | High risk of ILUC, food vs. fuel competition, high water/fertilizer use |

| Second-Generation | Agricultural waste, Wood chips, Switchgrass | Reduced land use impact, uses non-food biomass, but complex processing |

| Advanced (e.g., Algae) | Algae grown in bioreactors | High yield per acre, uses non-arable land/water, minimal habitat disruption |

Optimize your lab's biofuel research with precision equipment from KINTEK. Whether you're analyzing feedstock, developing advanced biofuels, or assessing environmental impact, KINTEK provides reliable lab equipment and consumables tailored to your sustainability goals. Contact our experts today to enhance your biofuel testing and development processes!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Wall Mounted Water Distillation Unit

- Evaporation Boat for Organic Matter

People Also Ask

- What are the different methods of cooling after heat treatment? A Guide to Quenching for Optimal Metal Properties

- How is a sputtering target made? A Guide to Manufacturing High-Performance Thin Film Sources

- What is the fundamental of sputter deposition? A Guide to Atomic-Level Thin Film Coating

- How is a laboratory drying oven used for moisture determination in biomass? Precision Analysis & Energy Metrics

- What is the difference between hardening and tempering? Achieve the Perfect Balance of Strength and Toughness

- What temperature does molten steel melt? Understand the Melting Range, Not a Single Point

- Can biomass be used to produce energy? Unlock Renewable Power from Organic Materials

- What is fast pyrolysis? Unlock the Potential of Biomass for Biofuel and Bio-char