In the right context, sieve analysis is a highly accurate and reproducible method for determining the particle size distribution of granular materials. Its accuracy, however, is not absolute and depends entirely on correct procedure, proper sample size, and an understanding of its inherent limitations, such as a finite resolution and a minimum particle size threshold.

The core takeaway is that the reliability of sieve analysis is a direct function of operator diligence. While the method itself is fundamentally sound and cost-effective, its accuracy is easily compromised by procedural errors, most notably using a sample size that is too large.

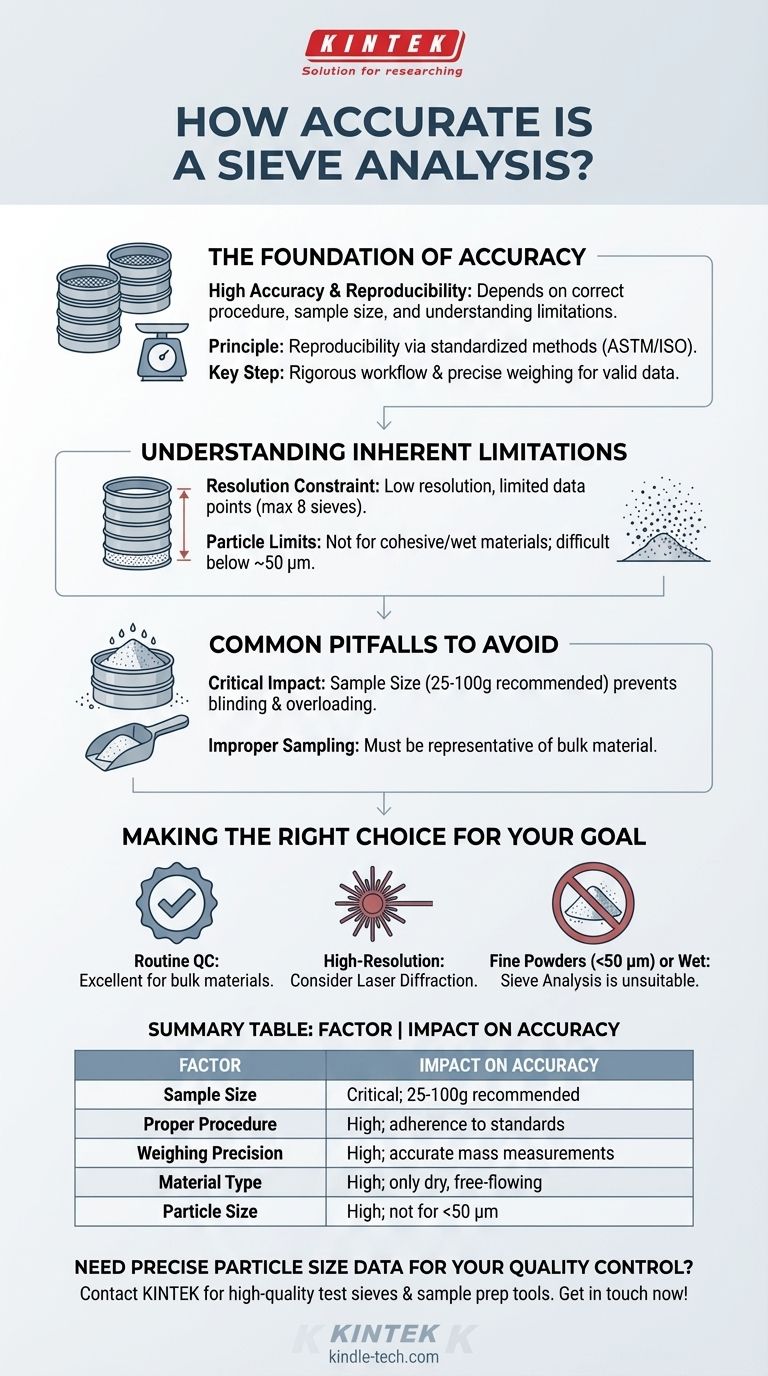

The Foundation of Sieve Analysis Accuracy

Sieve analysis is trusted in countless industries because its accuracy is built on a foundation of standardized methods and straightforward physical principles. When these standards are respected, the results are highly reliable.

The Principle of Reproducibility

The method's primary advantage is its reproducibility. Because the process is simple and follows established international standards (like ASTM or ISO), two different labs analyzing the same material should achieve very similar results.

This consistency makes it a cornerstone for quality control applications where the goal is to verify that a material consistently meets a specific size specification.

The Importance of a Rigorous Workflow

Accuracy is achieved by meticulously following a multi-step process. Each step is critical for a valid result.

The typical workflow includes method development, careful sampling, pre-drying the sample, precisely weighing the empty sieves, adding the sample, performing the sieving action, and then back-weighing the separated fractions. Any deviation compromises the final data.

Weighing: The Critical Measurement Step

The quantitative data from a sieve analysis comes entirely from weighing. First, each individual sieve and the bottom pan are weighed while empty. After the sieving process, each sieve is weighed again with its retained particle fraction.

The difference in weight provides the mass for each size class, which is then used to build the particle size distribution curve. Precision here is non-negotiable for accuracy.

Understanding the Inherent Limitations

While accurate for its purpose, sieve analysis is not a perfect or universal solution. Its accuracy is bounded by several key technical constraints that you must understand before choosing this method.

The Resolution Constraint

A standard stack of test sieves typically uses a maximum of eight sieves. This means your final particle size distribution is based on just eight data points.

This provides a good overview but is a low-resolution measurement. It cannot reveal fine details in the distribution curve that may be present between two sieve sizes.

The Particle Size and Type Limitation

Sieve analysis is only effective for dry, free-flowing particles. It is not suitable for cohesive materials, slurries, or wet suspensions.

Furthermore, there is a practical lower limit to the particle size. Standard woven-wire sieves become difficult to manufacture and use below approximately 50 micrometers (µm), limiting its use for very fine powders.

Common Pitfalls That Compromise Accuracy

The most significant threats to accuracy in sieve analysis are not from the equipment itself, but from operator error. Avoiding these common pitfalls is essential for trustworthy results.

The Critical Impact of Sample Size

Using a sample that is too large is the most common mistake. This causes blinding, where the sieve mesh becomes clogged, and overloading, where particles do not have a fair chance to encounter an open aperture and pass through.

For most materials, a sample size between 25 and 100 grams is recommended. The ideal weight should be determined experimentally to ensure each particle can be properly tested by the sieve surface.

Improper Sampling

The small sample used for the analysis must be perfectly representative of the entire batch of material. If the initial sample is drawn improperly (e.g., only from the top of a container), the results will be accurate for the sample, but completely inaccurate for the bulk material. Using a sample splitter is the correct way to reduce a larger batch to a testable size.

Making the Right Choice for Your Goal

To decide if sieve analysis is right for you, consider your primary objective.

- If your primary focus is routine quality control for bulk materials (like sand, gravel, or grain): Sieve analysis is an excellent, reliable, and cost-effective method for ensuring consistency.

- If your primary focus is high-resolution characterization of a powder's distribution: You should consider alternative methods like laser diffraction, as the limited data points from sieving will not provide the detail you need.

- If your primary focus is analyzing fine powders below 50 µm or wet materials: Sieve analysis is fundamentally unsuitable, and you must use a different characterization technique.

Understanding these factors allows you to confidently apply sieve analysis and trust the data it provides for its intended purpose.

Summary Table:

| Factor | Impact on Accuracy |

|---|---|

| Sample Size | Critical; 25-100g recommended to prevent blinding/overloading. |

| Proper Procedure | High; adherence to ASTM/ISO standards ensures reproducibility. |

| Weighing Precision | High; all quantitative data is derived from accurate mass measurements. |

| Material Type | High; only suitable for dry, free-flowing particles. |

| Particle Size | High; not suitable for particles finer than ~50 µm. |

Need precise particle size data for your quality control?

At KINTEK, we specialize in providing the right laboratory equipment, including high-quality test sieves and sample preparation tools, to ensure your sieve analysis is accurate and reproducible. Our experts can help you select the perfect equipment for your specific material and application.

Contact us today to discuss your lab's particle analysis needs and let KINTEK be your partner in precision. Get in touch now!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Single Horizontal Jar Mill

People Also Ask

- What is the process of sieve separation? A Guide to Precise Particle Size Analysis

- How do we select a sieve? A Systems-Based Guide to Accurate Particle Separation

- What is ASTM standard sieve? Ensure Precision in Particle Size Analysis

- What is a test sieve? A Precision Tool for Accurate Particle Size Analysis

- How is particle size determined by sieve analysis? A Step-by-Step Guide to Material Gradation

- Why would you use a sieve on your soil sample? To Determine Grain Size Distribution for Engineering

- What is the diameter of a test sieves? A Guide to Choosing the Right Size for Your Lab

- What is the use of sieving in laboratory? Ensure Material Quality & Accurate Particle Analysis