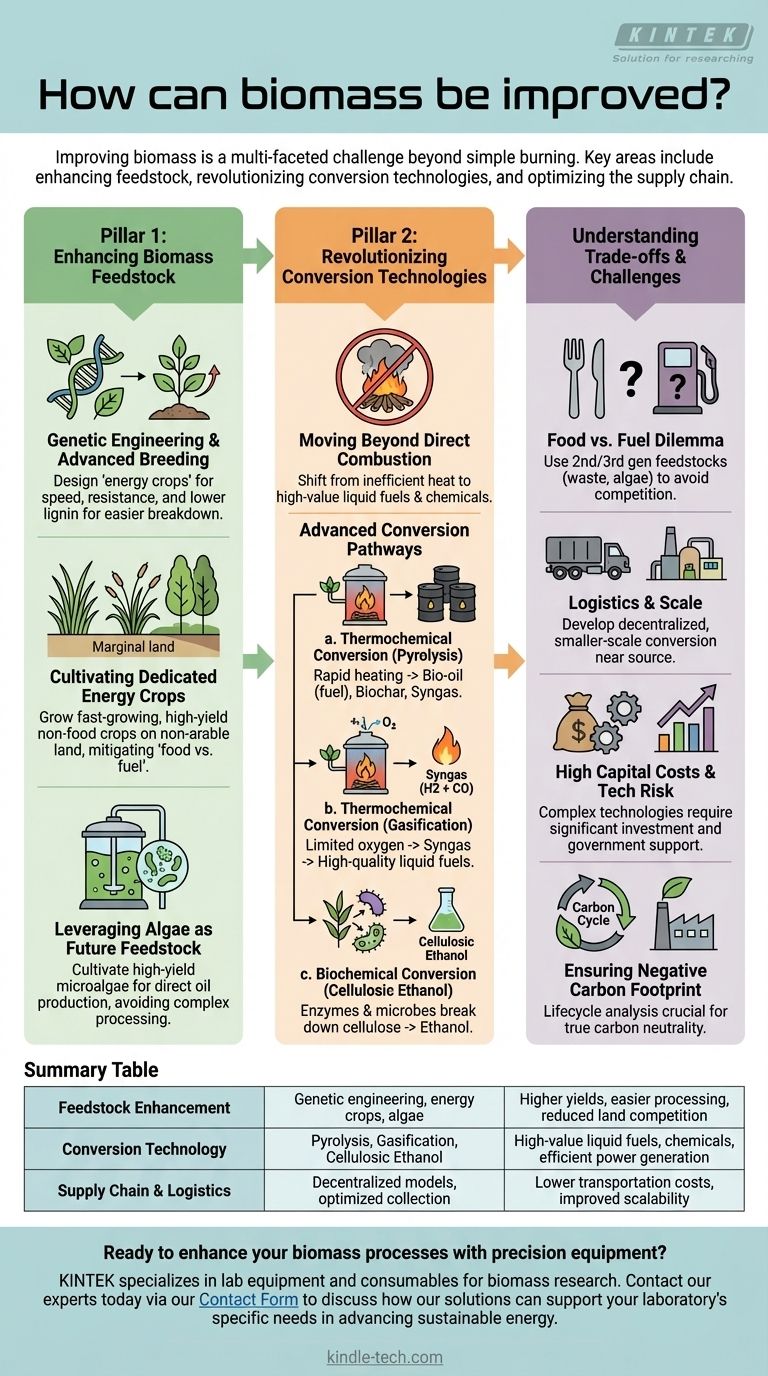

Improving biomass is a multi-faceted challenge that moves far beyond simply burning wood more efficiently. The most significant improvements involve three core areas: enhancing the raw biological material (the feedstock), revolutionizing the technologies that convert it into energy, and optimizing the entire supply chain. This means applying advanced techniques like genetic engineering to crops, developing sophisticated chemical reactors for pyrolysis and gasification, and creating new logistical models for a decentralized resource.

The future viability of biomass as a major energy source does not lie in improving traditional combustion. Instead, it depends on a fundamental shift towards advanced biorefineries that can transform diverse, low-value biomass into high-value, standardized liquid fuels and chemicals, making it a direct competitor to fossil fuels.

Pillar 1: Enhancing the Biomass Feedstock

The quality and type of raw material are the foundation of the entire energy conversion process. Improving the feedstock itself provides an enormous strategic advantage before any processing begins.

Genetic Engineering and Advanced Breeding

We can now design "energy crops" for specific purposes. Through genetic modification and selective breeding, we can create plants that grow faster, require less water and fertilizer, and are more resistant to pests and disease.

Critically, we can also alter a plant's chemical composition. By reducing the content of lignin, the tough polymer that makes wood rigid, we make the biomass much easier and cheaper to break down during biochemical conversion processes.

Cultivating Dedicated Energy Crops

Instead of relying solely on agricultural leftovers like corn stover, a key strategy is to cultivate non-food crops specifically for energy.

Fast-growing grasses like switchgrass and miscanthus, or trees like poplar, are highly efficient at converting sunlight into cellulose. They can often be grown on marginal land that is not suitable for food production, helping to mitigate the "food vs. fuel" debate.

Leveraging Algae as a Future Feedstock

Microalgae represent a potential leap forward for biomass. They can be cultivated in ponds or closed bioreactors on non-arable land and can have growth rates far exceeding those of terrestrial plants.

Some algae strains are engineered to produce oils directly, which can then be refined into biodiesel or jet fuel. This avoids the complex steps of breaking down cellulose and offers a much higher yield per acre.

Pillar 2: Revolutionizing Conversion Technologies

How we turn solid biomass into usable energy is where the most dramatic improvements are occurring. The goal is to move from inefficient, low-value heat production to the creation of high-value, transportable liquid fuels and chemicals.

Moving Beyond Direct Combustion

Simply burning raw biomass is the oldest method. While modern combustion plants are more efficient and have better emissions controls, the process is still limited. It primarily generates heat and electricity, and it struggles to compete with the energy density of fossil fuels.

Thermochemical Conversion: Pyrolysis and Gasification

This is a family of processes that uses heat in a controlled environment to deconstruct biomass.

- Pyrolysis: Involves rapidly heating biomass in the absence of oxygen. This produces a liquid known as bio-oil or pyrolysis oil, which can be stored, transported, and upgraded into gasoline or diesel replacements. It also co-produces biochar (a valuable soil amendment) and syngas.

- Gasification: Involves heating biomass with a limited amount of oxygen. This process doesn't burn the biomass completely but instead converts it into a flammable gas mixture called synthesis gas (syngas)—primarily hydrogen and carbon monoxide. This syngas is a flexible chemical building block for producing high-quality liquid fuels through processes like Fischer-Tropsch synthesis.

Biochemical Conversion: Cellulosic Ethanol

This pathway uses enzymes and microorganisms to break down the cellulose and hemicellulose in biomass into simple sugars.

These sugars are then fermented to produce fuels like ethanol. This is known as second-generation or cellulosic ethanol, and it is a major improvement over first-generation ethanol from corn or sugarcane because it uses non-food sources like wood chips, grasses, and agricultural waste.

Understanding the Trade-offs and Challenges

Pursuing these improvements requires a clear-eyed view of the significant hurdles that remain. Objectivity is critical for making sound strategic decisions.

The Food vs. Fuel Dilemma

Using prime agricultural land and food crops (like corn) for energy production is a major ethical and economic concern. The most viable improvement strategies focus on second- and third-generation feedstocks (waste, non-food crops, algae) that do not compete with the food supply.

The Problem of Logistics and Scale

Biomass is bulky, wet, and has a low energy density compared to oil or coal. This makes it expensive to collect, store, and transport to a central processing facility. A key challenge is developing decentralized or smaller-scale conversion plants that can be located closer to the source of the feedstock.

High Capital Costs and Technology Risk

Advanced biorefineries that use pyrolysis, gasification, or cellulosic conversion are complex and expensive to build. The technology is still maturing, and the economic viability often depends on volatile energy prices and government policy, making it a high-risk investment.

Ensuring a Negative Carbon Footprint

The claim of "carbon neutrality" must be carefully scrutinized. The entire lifecycle—from cultivation and harvesting to transportation and processing—must be analyzed. If fossil fuels are used heavily in the supply chain, or if land use changes lead to deforestation, the net carbon benefit can be lost.

Making the Right Choice for Your Goal

The optimal strategy for improving biomass depends entirely on your specific objective, resources, and scale.

- If your primary focus is grid-scale electricity: Co-firing refined biomass pellets in existing coal plants or building new gasification-combined cycle (IGCC) power plants is the most direct path.

- If your primary focus is creating sustainable transportation fuels: Pursuing cellulosic ethanol or pyrolysis-to-biofuel technologies offers the most promise for creating fungible, drop-in liquid fuels.

- If your primary focus is decentralized rural energy: Simple, robust gasifiers for local power and heat generation or anaerobic digesters for converting farm waste into biogas are proven and effective solutions.

- If your primary focus is high-value chemical production: Using syngas from gasification as a chemical feedstock to produce plastics, fertilizers, and other materials is a frontier that transforms biomass from a fuel source into a renewable industrial input.

By strategically advancing both the feedstocks and the conversion technologies, biomass can be transformed from a marginal resource into a cornerstone of a diversified and sustainable energy portfolio.

Summary Table:

| Improvement Area | Key Strategies | Primary Benefits |

|---|---|---|

| Feedstock Enhancement | Genetic engineering, dedicated energy crops (e.g., switchgrass), algae cultivation | Higher yields, easier processing, reduced land competition |

| Conversion Technology | Pyrolysis (bio-oil), Gasification (syngas), Cellulosic Ethanol | High-value liquid fuels, chemicals, efficient power generation |

| Supply Chain & Logistics | Decentralized processing models, optimized collection | Lower transportation costs, improved scalability |

Ready to enhance your biomass processes with precision equipment?

KINTEK specializes in lab equipment and consumables for biomass research and development. Whether you are developing new feedstocks, optimizing pyrolysis reactions, or scaling up gasification processes, our reliable tools help you achieve accurate and reproducible results.

Contact our experts today via our Contact Form to discuss how our solutions can support your laboratory's specific needs in advancing sustainable energy.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What industry is heat treatment? The Foundational Process Behind Aerospace, Automotive & Energy

- What is the minimum temperature for sintering? It Depends on Your Material's Melting Point

- How is a sample analysis done in FTIR? A Step-by-Step Guide to Reliable Results

- What are the alternatives to rotavap? Find the Right Solvent Removal Method for Your Lab

- What are the advantages of the fluidization process? Achieve Superior Temperature Control & Efficiency

- What are the factors that affect sample size? Optimize Your Study's Power and Precision

- What is sintering process related to? Mastering Powder-to-Solid Manufacturing

- What is the residence time in flash pyrolysis? A Sub-2-Second Race for Maximum Bio-Oil