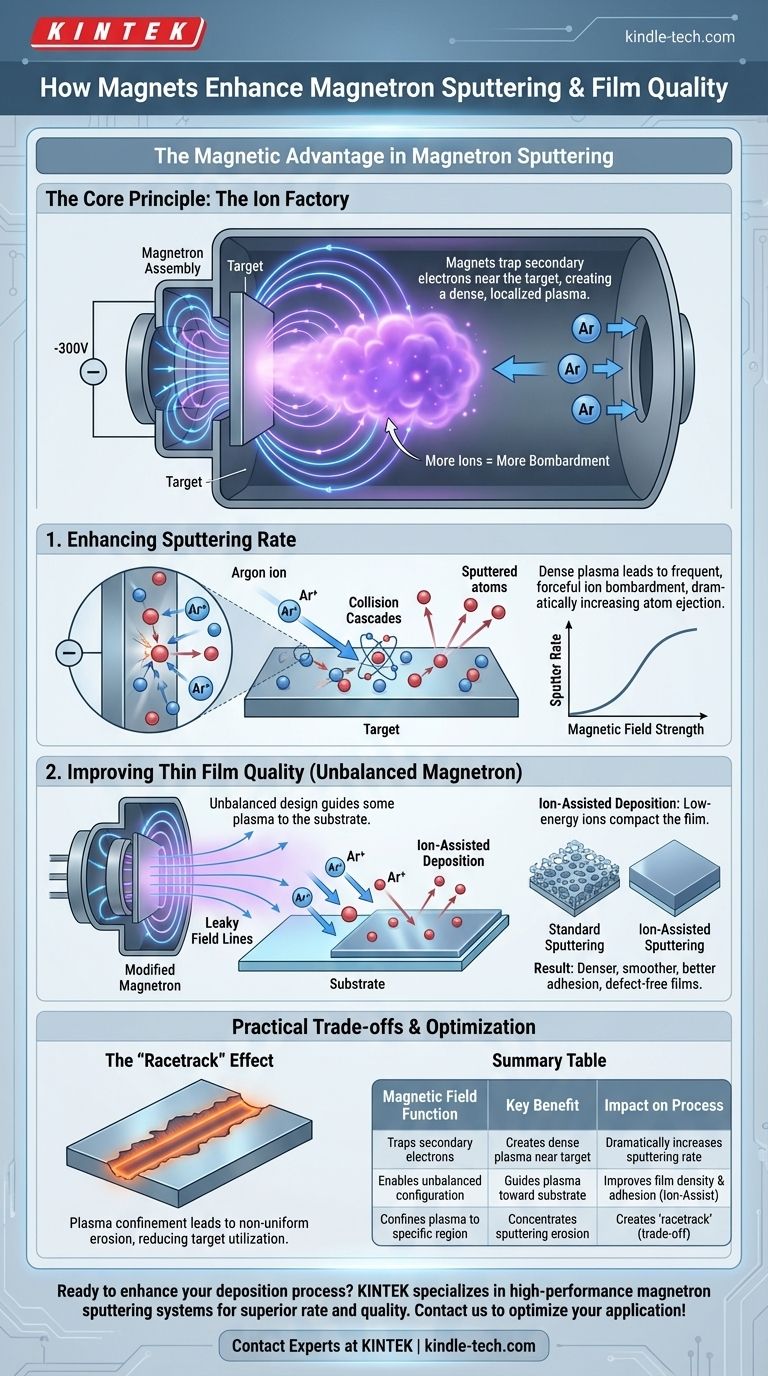

In magnetron sputtering, magnets dramatically increase the sputtering rate by trapping electrons near the target surface. This confinement creates a dense, localized plasma that generates a massive number of ions, leading to more frequent and forceful bombardment of the target. This same principle, when modified, can guide a portion of the plasma toward the substrate, actively improving the quality and density of the growing thin film.

The core function of the magnetic field is not to act on the sputtered material itself, but to create a highly efficient "ion factory" at the target's surface. This enhancement is the key to both the speed of deposition and the quality of the final film.

The Foundation: How Sputtering Works

To understand the magnetic enhancement, we must first understand the basic sputtering process. It is fundamentally an energetic, physical collision process.

The Role of Negative Voltage

A high negative voltage (e.g., -300V) is applied to the source material, known as the target. This target is placed in a vacuum chamber filled with a small amount of an inert gas, like Argon.

Ion Bombardment and Atom Ejection

The negative voltage on the target attracts the positively charged Argon ions from the surrounding plasma. These ions accelerate and collide with the target surface at high speed.

This impact transfers kinetic energy into the target's atomic lattice, creating collision cascades. If enough energy is directed back toward the surface, a target atom is ejected, or "sputtered."

The Inefficiency of Basic Sputtering

Without a magnetic field, this process is inefficient. The plasma is weak, and many electrons (which are crucial for creating ions) are lost to the chamber walls without doing useful work. This requires higher gas pressures and results in a low deposition rate.

The Magnetic Enhancement: Creating High-Density Plasma

The introduction of a magnetic field behind the target fundamentally changes the dynamics of the plasma and solves the inefficiency problem.

Trapping Secondary Electrons

When ions strike the target, they not only sputter atoms but also knock out secondary electrons. The magnetic field, oriented parallel to the target face, traps these electrons.

Instead of escaping, the electrons are forced to follow a helical path along the magnetic field lines, creating a dense cloud of electron activity directly in front of the target.

The Cascade of Ionization

These trapped, spiraling electrons undergo significantly more collisions with neutral Argon gas atoms. Each collision has a high probability of knocking an electron off the Argon atom, creating a new Argon ion.

This process feeds on itself, creating a dense, self-sustaining plasma with a very high ion concentration precisely where it's needed most—right next to the target.

The Direct Impact on Sputter Rate

A higher density of ions means a much higher flux of ions bombarding the target. This directly translates to a dramatically higher rate of sputtered atoms being ejected, increasing the deposition rate by orders of magnitude.

Improving Film Quality: From Plasma to Substrate

While a high rate is important, the quality of the deposited film is often paramount. Magnets are also critical for controlling film properties like density, adhesion, and uniformity.

The Unbalanced Magnetron Solution

In a standard "balanced" magnetron, the magnetic field is designed to perfectly confine the plasma at the target. In an unbalanced magnetron, the outer magnetic field is made intentionally weaker or "leaky."

This leaky field allows some of the plasma—and the electrons that sustain it—to extend away from the target and follow the field lines toward the substrate where the film is growing.

Ion-Assisted Deposition

The result is a low-energy ion bombardment of the growing film itself. This is known as ion-assisted deposition. The neutrally charged sputtered atoms arrive at the substrate, and this concurrent ion bombardment acts like an atomic-scale hammer.

This process provides extra energy to the depositing atoms, allowing them to arrange themselves into a denser, more organized structure. It knocks out loosely bonded atoms and fills microscopic voids.

The Result: Denser, Higher-Quality Films

This ion assistance produces films that are more compact, have better adhesion to the substrate, and are free of defects like pinholes. The film's structural and electrical properties are significantly enhanced compared to a film deposited without this effect.

Understanding the Practical Trade-offs

The magnetic field is not a simple "on/off" switch; its precise configuration has critical consequences for the sputtering process.

Magnetic Field Design is Critical

The strength and shape of the magnetic field directly influence the density and location of the plasma. A poorly designed field can lead to low rates and poor film uniformity.

The "Racetrack" and Target Utilization

Because the plasma is trapped in the magnetic field region, sputtering does not occur uniformly across the target face. Instead, it erodes a distinct groove known as a "racetrack."

This leads to inefficient use of the expensive target material, as the center and outer edges are often left untouched. Advanced magnetron designs aim to move this racetrack over time to improve target utilization.

Making the Right Choice for Your Goal

The magnetron configuration you use should be dictated by the primary goal of your thin film deposition process.

- If your primary focus is maximizing deposition rate: A strongly-confined, balanced magnetron design will create the densest possible plasma at the target, maximizing the sputtering yield.

- If your primary focus is achieving the highest film density and adhesion: An unbalanced magnetron is essential to provide the ion-assisted deposition needed to produce compact, high-performance films.

- If your primary focus is material efficiency and cost: Pay close attention to magnetron designs that promise high target utilization by sweeping the magnetic field to create a more uniform erosion profile.

Ultimately, the magnetic field transforms sputtering from a simple physical process into a precisely controlled and highly efficient tool for engineering materials at the atomic level.

Summary Table:

| Magnetic Field Function | Key Benefit | Impact on Process |

|---|---|---|

| Traps secondary electrons | Creates dense plasma near target | Dramatically increases sputtering rate |

| Enables unbalanced configuration | Guides plasma toward substrate | Improves film density and adhesion via ion bombardment |

| Confines plasma to specific region | Concentrates sputtering erosion | Creates 'racetrack' on target (a trade-off) |

Ready to enhance your thin film deposition process? KINTEK specializes in high-performance lab equipment, including advanced magnetron sputtering systems designed for superior deposition rates and film quality. Whether your priority is speed, material density, or cost-efficiency, our solutions are tailored to meet your laboratory's specific needs. Contact our experts today to discuss how we can optimize your sputtering applications!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is plasma enhanced chemical vapor deposition PECVD equipment? A Guide to Low-Temperature Thin Film Deposition