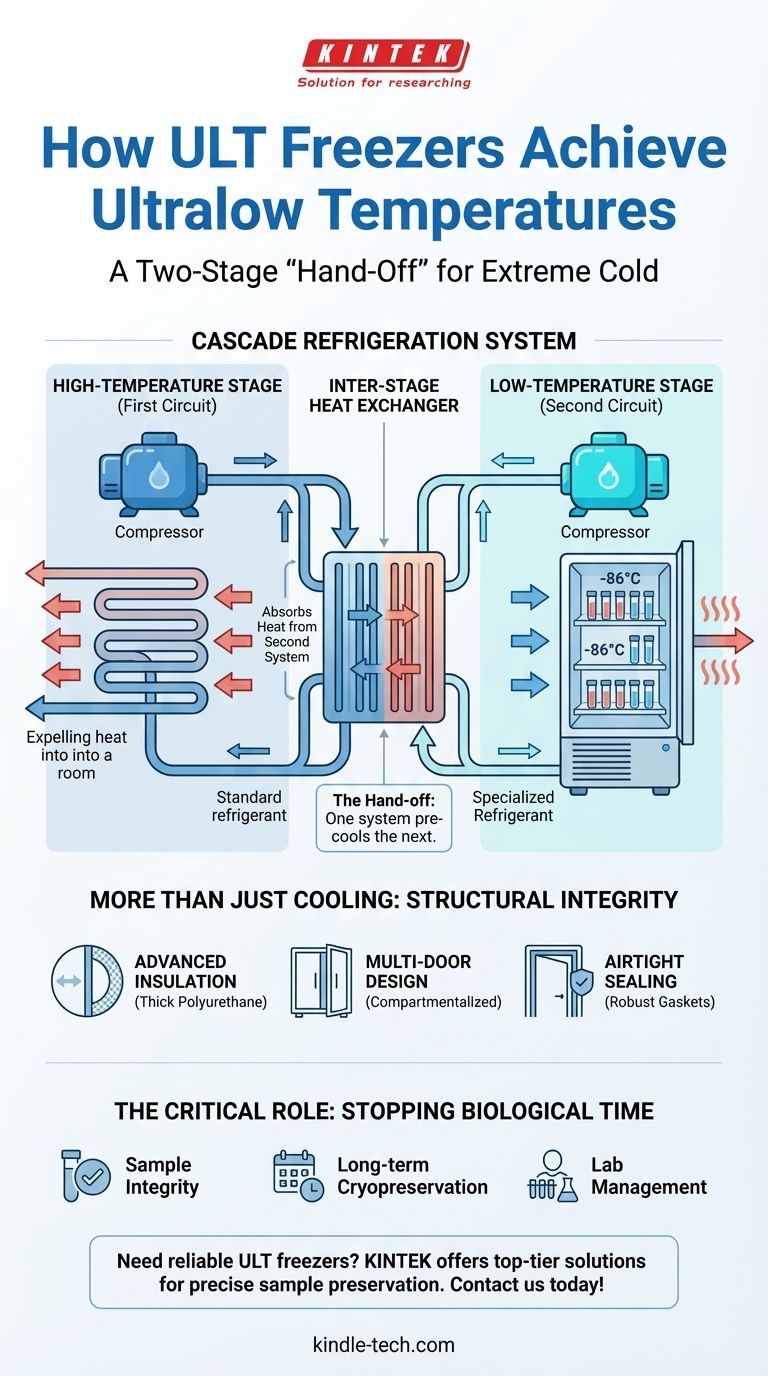

At its core, an ultra-low temperature (ULT) freezer achieves its extreme cold by using two refrigeration systems working in tandem. Instead of a single powerful compressor, it employs a multi-stage process called cascade refrigeration. A primary, high-temperature refrigeration circuit cools a secondary, low-temperature circuit, which then chills the freezer's interior to temperatures as low as -86°C.

The key to reaching ultra-low temperatures isn't brute force; it's a clever, two-step "hand-off." One refrigeration system pre-cools a second, more specialized system, allowing that second system to extract heat far more effectively and achieve temperatures impossible for a single-stage unit.

The Heart of the System: Cascade Refrigeration

A standard freezer struggles to reach temperatures below -40°C because the pressure difference required becomes too great for a single compressor. Cascade refrigeration solves this by dividing the work into two optimized stages.

The High-Temperature Stage (First Circuit)

This first system functions much like a common household freezer. It uses a compressor and a standard refrigerant to begin the cooling process.

However, its primary job is not to cool the storage chamber. Its sole purpose is to absorb heat from the second refrigeration system.

The Inter-Stage Heat Exchanger (The Hand-off)

This is the critical component connecting the two systems. The evaporator (the cold part) of the first circuit makes contact with the condenser (the hot part) of the second circuit.

Heat is transferred from the low-temperature system to the high-temperature system at this point, effectively pre-cooling the second circuit.

The Low-Temperature Stage (Second Circuit)

This circuit uses a different refrigerant with a much lower boiling point, specifically chosen for performance at extreme cold.

Because its "hot" side is already being chilled by the first stage, this second system can operate efficiently to pull the remaining heat out of the freezer's interior, reaching the target temperature of -80°C or below.

Expelling the Heat

The heat gathered by the first circuit is ultimately expelled into the surrounding room through a conventional air-cooled condenser and fan. This final heat exchange is why ULT freezers generate significant amounts of heat and are often quite loud.

More Than Just Cooling: Structural Integrity

Achieving ultra-low temperatures is only half the battle; maintaining them requires specialized construction designed to prevent heat from entering.

Advanced Insulation

The walls of a ULT freezer are packed with thick, high-performance polyurethane insulation. This material is essential for minimizing heat transfer from the warmer external environment.

Multi-Door Design

Most units feature a main, heavy outer door and multiple inner doors. This compartmentalizes the interior, so when you open one section to retrieve a sample, you minimize the amount of cold air lost and warm air introduced.

Airtight Sealing

The doors are sealed with robust, gel-like silicone gaskets and often feature strong latching mechanisms. This creates an airtight seal that prevents ambient air from leaking in, which would cause ice build-up and force the compressors to work harder.

Understanding the Trade-offs

The cascade system is highly effective but comes with inherent consequences that are important to manage in a lab environment.

High Energy Consumption

Running two independent refrigeration systems simultaneously requires a significant amount of electricity. ULT freezers are among the most energy-intensive pieces of equipment in a typical lab.

Heat and Noise Output

The compressors and the fan-cooled condenser constantly work to expel heat from the system. This process generates substantial background noise and adds a considerable heat load to the room, impacting HVAC requirements.

System Complexity

A two-stage cascade system is mechanically more complex than a standard freezer. This intricacy means it requires specialized technicians for maintenance and repair.

The Critical Role of a ULT Freezer

Understanding these principles reveals that a ULT freezer is a highly engineered environment, not just a cold box. Its design choices are entirely focused on stability.

- If your primary focus is sample integrity: The cascade system's ability to maintain stable, ultra-low temperatures is what prevents the denaturation of sensitive biomolecules like proteins and mRNA.

- If your primary focus is long-term cryopreservation: The combination of robust insulation, tight seals, and precise temperature control ensures minimal fluctuations, which is vital for the viability of cells and tissues.

- If your primary focus is lab management: The system's operational demands mean you must account for its high energy use and heat output in your facility's electrical and HVAC planning.

Ultimately, a ULT freezer's design is a sophisticated solution engineered for one purpose: to stop biological time and preserve the integrity of invaluable scientific materials.

Summary Table:

| Key Component | Function |

|---|---|

| High-Temperature Stage | First circuit cools the second system using a standard refrigerant. |

| Inter-Stage Heat Exchanger | Transfers heat from the low-temperature circuit to the high-temperature circuit. |

| Low-Temperature Stage | Second circuit uses a specialized refrigerant to chill the interior to -80°C or below. |

| Advanced Insulation | Thick polyurethane walls minimize heat transfer from the environment. |

| Multi-Door Design | Compartmentalizes the interior to reduce cold air loss when accessing samples. |

Need reliable, high-performance ULT freezers for your lab? KINTEK specializes in providing top-tier lab equipment, including ultra-low temperature freezers designed for precise sample preservation. Our solutions ensure stable temperatures for sensitive biomolecules, cells, and tissues, helping you maintain sample integrity and streamline your research. Contact us today to find the perfect ULT freezer for your laboratory needs!

Visual Guide

Related Products

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs