At their core, ultra-low temperature (ULT) freezers increase energy efficiency through a combination of advanced design and intelligent operation. Unlike standard freezers, modern ULTs employ superior insulation, compartmentalized inner doors to trap cold air, and optimized refrigeration cycles with features like variable-speed compressors. This holistic approach minimizes the energy required to maintain extremely low temperatures, even in a busy lab environment with frequent door openings.

The central challenge for a ULT freezer is maintaining a stable, ultra-low temperature 24/7. Modern efficiency gains come not from a single breakthrough, but from a systematic effort to reduce energy waste at every point: generating the cold, keeping the cold in, and recovering quickly when it's lost.

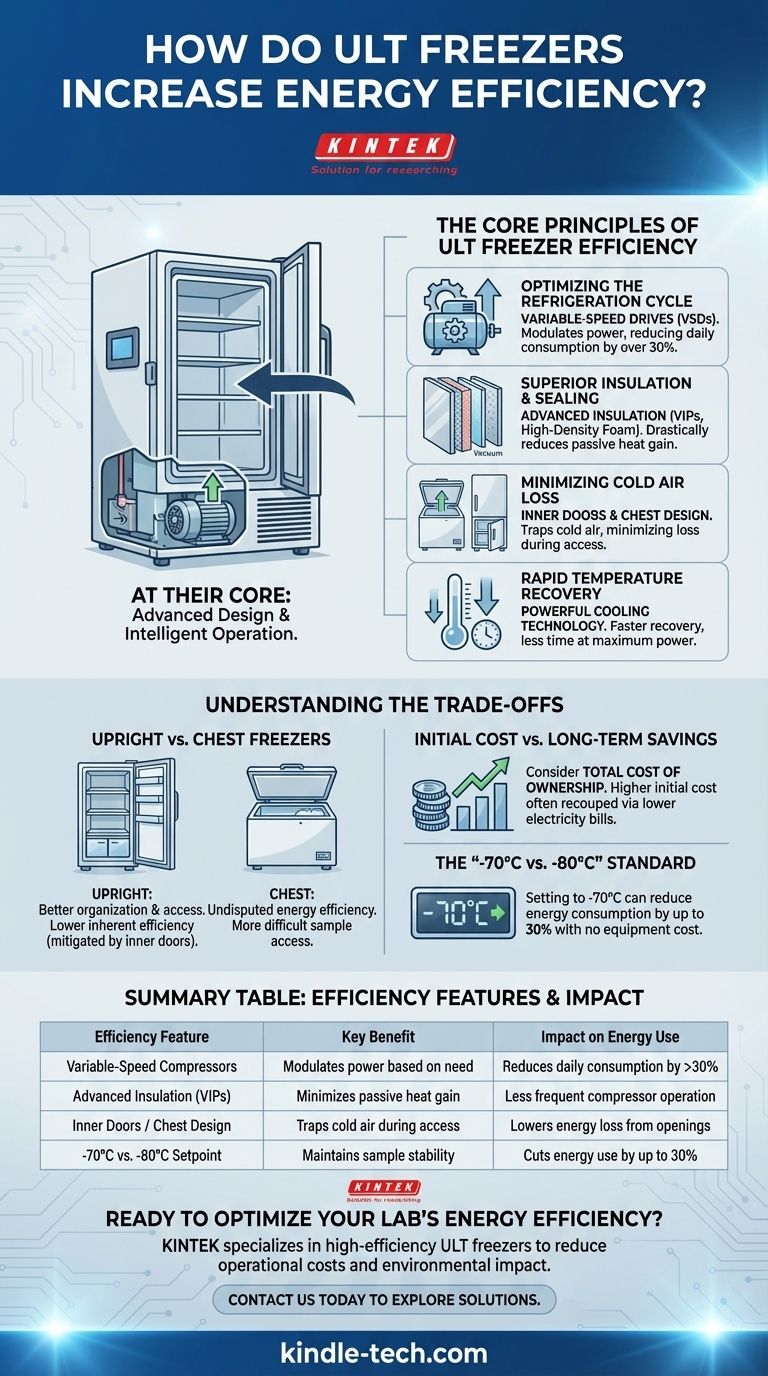

The Core Principles of ULT Freezer Efficiency

A ULT freezer is one of the most energy-intensive pieces of equipment in a laboratory. Understanding how manufacturers combat this consumption is key to managing operational costs and environmental impact.

Optimizing the Refrigeration Cycle

The compressor is the heart of the freezer and a primary consumer of energy. Early models used simple, single-speed compressors that were either on at full power or off.

Modern systems often use variable-speed drives (VSDs) for compressors and fans. This technology allows the freezer to modulate its power usage, running at a lower, more efficient speed to maintain temperature and ramping up only when needed, such as after a door opening. This alone can reduce daily energy consumption by over 30%.

Superior Insulation and Sealing

Keeping ambient heat out is just as important as generating cold. ULT freezers use advanced vacuum-insulated panels and high-density foam insulation.

These materials provide a much higher thermal resistance than traditional insulation, drastically reducing passive heat gain. This means the refrigeration system doesn't have to work as hard or as often to counteract warmth from the surrounding room.

Minimizing Cold Air Loss

Every time a freezer door is opened, cold, dense air spills out and is replaced by warmer, moist ambient air. This is a massive source of energy inefficiency.

To combat this, ULTs use two key design features:

- Inner Doors: Most upright ULTs have multiple, insulated inner doors that create separate compartments. When you open the main door, you only expose one small section, trapping the cold air in the rest of the unit.

- Chest Freezer Design: Chest freezers, which open from the top, are inherently more energy-efficient. Because cold air is denser than warm air, it naturally stays inside the freezer cavity when the lid is opened, minimizing loss.

Rapid Temperature Recovery

After a door opening, the freezer must work hard to remove the warmer air and return to its setpoint. Efficient freezers are equipped with powerful cooling technology that enables rapid temperature recovery.

By cooling the interior back down quickly, the system spends less time running at maximum power, saving significant energy over the long term.

Understanding the Trade-offs

Choosing a ULT freezer involves balancing efficiency with usability and cost. There is no single "best" option for every lab.

Upright vs. Chest Freezers

The most fundamental trade-off is between an upright and a chest freezer.

Chest freezers are the undisputed champions of energy efficiency due to their top-opening design that minimizes cold air loss. However, they can be more difficult to organize and access samples from, especially those at the bottom.

Upright freezers offer superior organization and easier access to samples. The penalty for this convenience is lower inherent efficiency, though features like inner doors help mitigate this.

Initial Cost vs. Long-Term Savings

The most energy-efficient freezers, particularly those with variable-speed drives or cutting-edge insulation, often carry a higher purchase price.

It's critical to evaluate the total cost of ownership. The premium paid for an efficient model can often be recouped within a few years through substantially lower electricity bills.

The "-70°C vs. -80°C" Standard

Many labs default to a setpoint of -80°C out of habit. However, a vast number of biological samples are perfectly stable at -70°C.

Setting your freezer just 10 degrees warmer can reduce energy consumption by up to 30%. This is the single most effective operational change you can make to save energy, with no equipment cost.

Making the Right Choice for Your Lab

Your decision should be guided by your lab's specific priorities regarding budget, sample access, and sustainability goals.

- If your primary focus is maximum energy efficiency and lowest operating cost: Choose a chest freezer, set the temperature to -70°C, and implement a strict regular maintenance schedule to prevent ice buildup.

- If your primary focus is frequent access and sample organization: An upright freezer with multiple, well-sealed inner doors is the superior choice, as it will minimize temperature fluctuations and search time.

- If your primary focus is cutting-edge performance and sustainability: Invest in a model with a variable-speed compressor, as the long-term energy savings and reduced environmental impact will justify the higher initial cost.

By understanding these core design principles and operational trade-offs, you can select and manage a ULT freezer that protects your valuable samples while minimizing its impact on your budget and the environment.

Summary Table:

| Efficiency Feature | Key Benefit | Impact on Energy Use |

|---|---|---|

| Variable-Speed Compressors | Modulates power based on need | Reduces daily consumption by over 30% |

| Advanced Insulation (e.g., VIP panels) | Minimizes passive heat gain | Less frequent compressor operation |

| Inner Doors / Chest Design | Traps cold air during access | Lowers energy loss from door openings |

| -70°C vs. -80°C Setpoint | Maintains sample stability at higher temps | Cuts energy use by up to 30% |

Ready to optimize your lab’s energy efficiency? KINTEK specializes in lab equipment and consumables, including high-efficiency ULT freezers designed to reduce operational costs and environmental impact. Our experts can help you select the right model for your sample access needs and sustainability goals. Contact us today to explore energy-saving solutions tailored to your laboratory!

Visual Guide

Related Products

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage