The most effective method for cleaning ball mill jars involves a multi-step process: first, a dry removal of bulk material, followed by either a wet cleaning with a suitable solvent or a dry "purge" run with an abrasive, inert powder like quartz sand. The choice between wet and dry methods depends entirely on the material you just milled and the required purity for your next batch.

The core principle of cleaning is not just visual cleanliness, but the complete elimination of microscopic residue. Failing to do so introduces cross-contamination, which can invalidate your subsequent milling results.

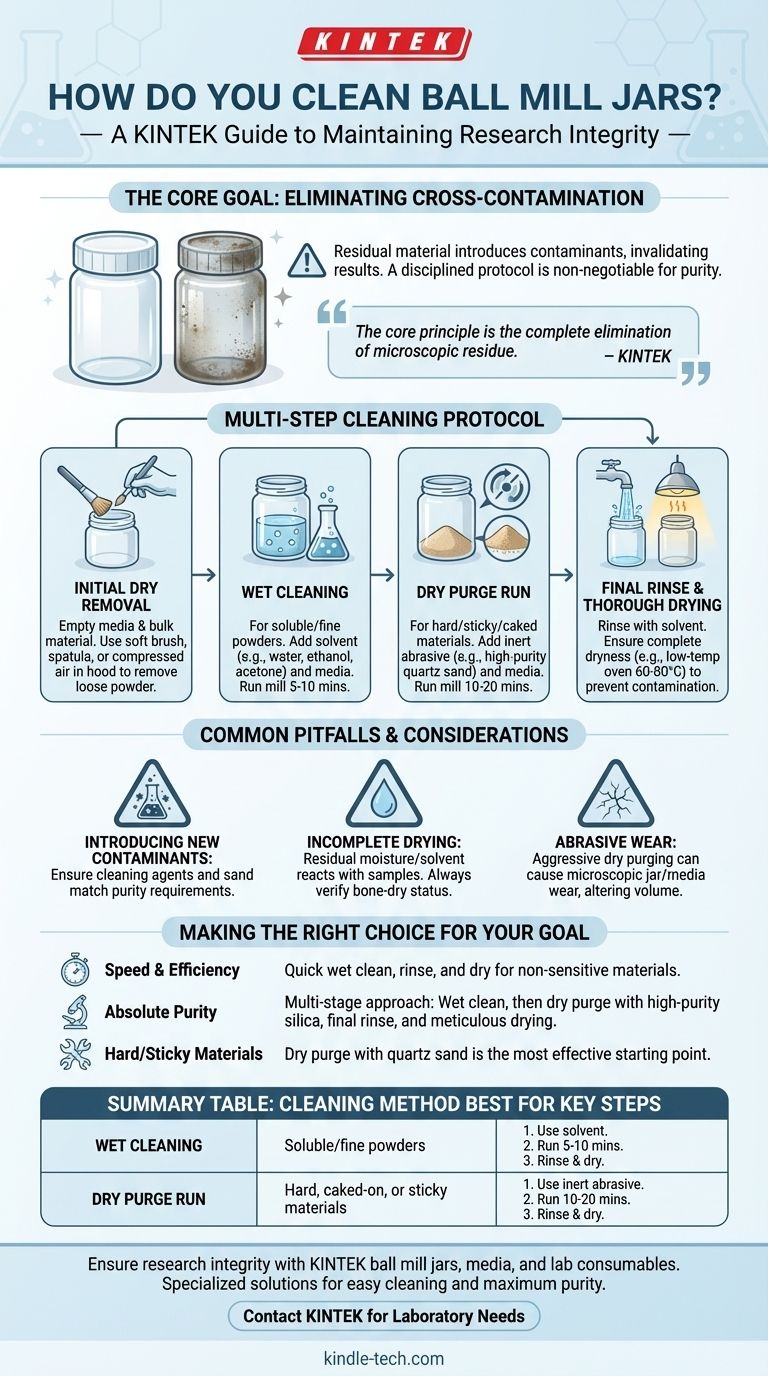

The Core Goal: Eliminating Cross-Contamination

Before detailing the procedure, it's crucial to understand why this process is so important. In material science, chemistry, and geology, the goal of ball milling is often to create a highly pure, homogenous powder.

The Problem with Residue

Even a few milligrams of leftover material from a previous run can act as a significant contaminant. This residue can alter the chemical composition, physical properties, and reactivity of your next sample, rendering your results unreliable.

A Disciplined Protocol is Non-Negotiable

A consistent, documented cleaning protocol is the foundation of repeatable and trustworthy results. It ensures that the only materials in your jar are the ones you intentionally put there.

A Step-by-Step Cleaning Protocol

Follow this general framework, adapting it based on the specific materials you are working with.

Step 1: Initial Dry Removal

First, carefully empty the jar of the milling media (the balls) and the bulk of your milled powder. Use a soft brush, a rubber spatula, or compressed air (in a ventilated hood) to remove as much loose powder as possible from the jar, lid, and media.

Step 2: Wet Cleaning with a Solvent

This method is ideal for materials that are soluble or form a fine, non-caked powder.

Place the milling media back into the jar. Add a solvent that effectively dissolves the milled material but does not react with the jar or media. Common choices include deionized water, ethanol, or acetone. Run the mill for 5-10 minutes to allow the solvent and media to scrub the internal surfaces.

Step 3: The Dry "Purge" Run

This method is superior for hard, caked-on, or sticky materials that solvents struggle to remove.

Place the media back into the jar and add an inert, abrasive cleaning material. High-purity quartz sand or silica is the industry standard. Run the mill for 10-20 minutes. The sand acts as a scouring agent, mechanically grinding away any remaining residue.

Step 4: Final Rinse and Thorough Drying

After either wet or dry cleaning, you must remove the cleaning agent itself. Rinse the jar and media thoroughly, typically with deionized water followed by ethanol or acetone to accelerate drying.

Drying is a critical, often overlooked step. Place the open jar and media in a low-temperature oven (typically 60-80°C) until completely dry. Any residual moisture or solvent is a contaminant.

Common Pitfalls and Considerations

A perfect cleaning process requires anticipating potential problems. Understanding these trade-offs is key to maintaining the integrity of both your samples and your equipment.

Pitfall 1: Introducing New Contaminants

Your cleaning agent can become a source of contamination. If you use industrial-grade quartz sand for a dry purge, you may introduce trace metals into your high-purity ceramic sample. Always match the purity of your cleaning agent to the requirements of your work.

Pitfall 2: Incomplete Drying

Residual moisture or solvent is a common cause of contamination. It can react with the next batch of material, especially if you are milling metals or moisture-sensitive chemicals. Always verify that every component is bone-dry.

Pitfall 3: Abrasive Wear

Aggressive dry purging, while effective, will cause microscopic wear on the interior of your jar and on the milling media over time. This is especially true for polymer (e.g., nylon) or softer ceramic (e.g., alumina) jars. This wear can slightly alter jar volume and, in extreme cases, introduce jar material into your sample.

Making the Right Choice for Your Goal

Your cleaning strategy should be dictated by your specific application and desired outcome.

- If your primary focus is speed and efficiency for non-sensitive materials: A quick wet clean with a suitable solvent followed by a thorough rinse and dry is often sufficient.

- If your primary focus is absolute purity for sensitive research (e.g., trace element analysis): A multi-stage approach is best. Use a wet clean, followed by a dry purge with high-purity silica, and then a final rinse and meticulous drying.

- If you are working with hard, sticky, or caked-on materials: A dry purge run with quartz sand is almost always the most effective starting point to mechanically remove the residue.

Ultimately, a rigorous cleaning protocol is an integral part of the milling process, ensuring the integrity and reliability of your results.

Summary Table:

| Cleaning Method | Best For | Key Steps |

|---|---|---|

| Wet Cleaning | Soluble or fine powders | 1. Use solvent (e.g., ethanol, acetone). 2. Run mill for 5-10 mins. 3. Rinse and dry thoroughly. |

| Dry Purge Run | Hard, caked-on, or sticky materials | 1. Use inert abrasive (e.g., quartz sand). 2. Run mill for 10-20 mins. 3. Rinse and dry thoroughly. |

Ensure your research integrity with the right equipment and protocols. KINTEK specializes in high-quality ball mill jars, milling media, and lab consumables designed for easy cleaning and maximum purity. Our experts can help you select the best materials for your specific application to prevent cross-contamination and achieve reliable results. Contact our team today to discuss your laboratory needs and optimize your milling process!

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Jar Mill with Agate Grinding Jar and Balls

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

People Also Ask

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results

- What is the average speed of a ball mill? Optimize Grinding with Critical Speed Calculations

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification

- What is the product size of a ball mill? Achieve Micron-Level Precision for Your Materials