To remove powder from a ball mill, the standard procedure involves stopping the machine, safely opening the grinding jar, and physically separating the finished powder from the grinding media (the balls). The most common method for this separation is pouring the contents through a sieve or screen that allows the powder to pass through while retaining the larger media.

The core challenge of removing material from a ball mill is not just the physical act of emptying the jar. It is about maximizing product recovery, preventing cross-contamination, and ensuring operator safety from airborne dust.

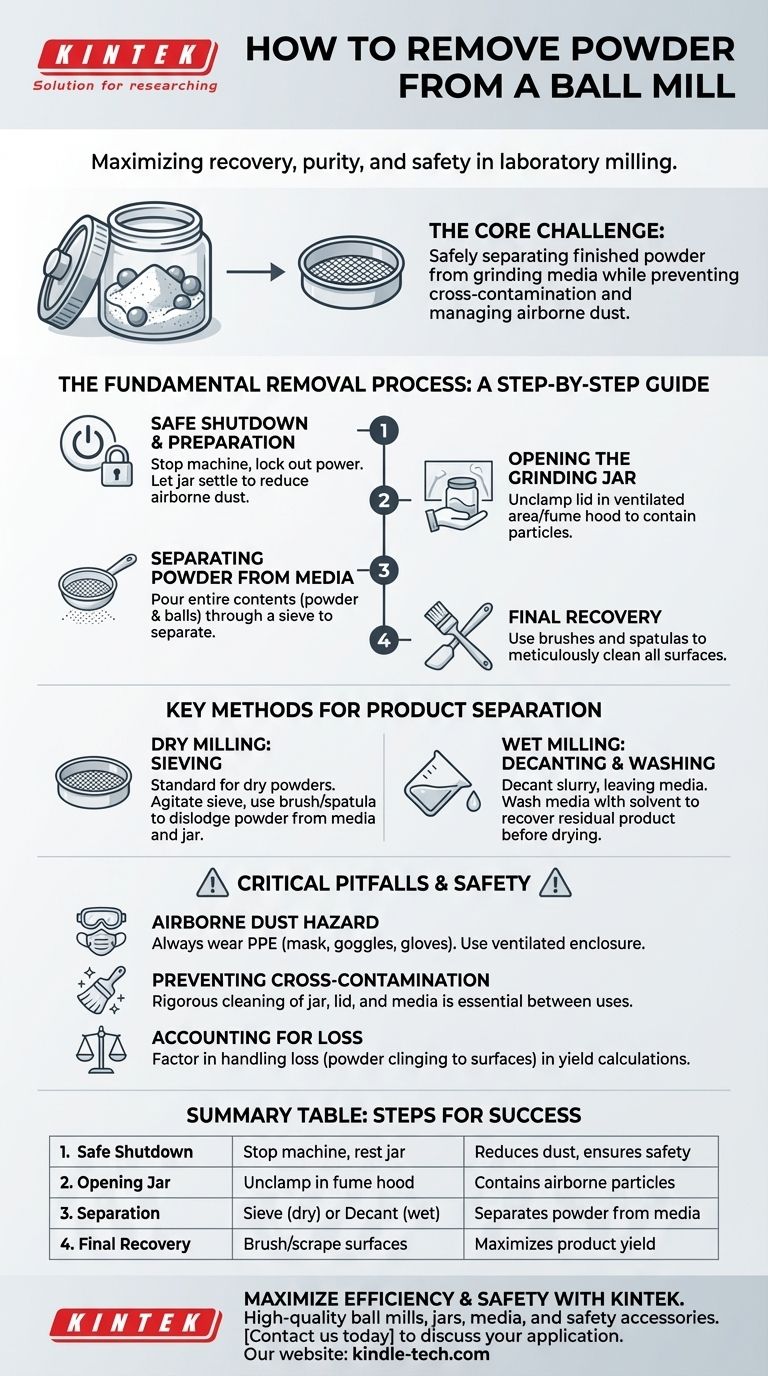

The Fundamental Removal Process: A Step-by-Step Guide

Successfully extracting your milled material requires a methodical and safe approach. Following a consistent procedure minimizes product loss and risk.

Step 1: Safe Shutdown and Preparation

Before any removal begins, ensure the ball mill has come to a complete stop and is electrically isolated, following proper lockout/tagout procedures if applicable. Allow the jar to rest for a few minutes; this lets fine, airborne particles inside the jar settle, reducing dust exposure when you open it.

Step 2: Opening the Grinding Jar

Carefully unclamp and remove the lid from the grinding jar. This should be done in a well-ventilated area or, ideally, inside a fume hood or glove box to contain any fine dust that may become airborne. Set the lid aside on a clean surface.

Step 3: Separating Powder from Media

The most direct method is to place a properly sized sieve over a clean collection pan. Carefully pour the entire contents of the jar—both powder and grinding media—onto the sieve. The powder will fall through into the pan, while the balls are caught on the screen.

Key Methods for Product Separation

The ideal separation technique depends on whether you performed a dry or wet milling operation.

For Dry Milling: Sieving

Sieving is the standard for dry powders. Gently agitating the sieve helps ensure all fine material passes through. A soft-bristled brush or a rubber spatula can be used to carefully dislodge powder that may be clinging to the grinding media and the interior walls of the jar.

For Wet Milling: Decanting and Washing

If milling was done in a liquid slurry, the process is different. First, carefully decant (pour off) the liquid slurry into a collection vessel, leaving the grinding media behind in the jar. You can then wash the media with a small amount of compatible solvent to recover any remaining product before drying the collected slurry to obtain your final powder.

Using Collection Systems and Brushes

For high-value materials, maximizing yield is critical. Use dedicated, clean brushes and spatulas to meticulously scrape the internal surfaces of the mill jar and lid. This ensures you recover as much product as possible.

Critical Safety and Contamination Pitfalls

The removal stage presents the highest risk of product contamination and operator exposure. Awareness of these pitfalls is essential for maintaining quality and safety.

The Hazard of Airborne Dust

Fine powders can easily become airborne and pose a significant inhalation hazard. Always wear appropriate personal protective equipment (PPE), including a dust mask or respirator, safety glasses, and gloves. Performing the transfer inside a ventilated enclosure is the best practice.

Preventing Cross-Contamination

If you use the mill for multiple materials, rigorous cleaning is non-negotiable. Any residual powder from a previous run can contaminate the next batch. The jar, lid, and grinding media must be thoroughly cleaned and dried between uses.

Accounting for Material Loss

Understand that 100% material recovery is practically impossible. A small amount of product will always be lost by clinging to the surfaces of the jar and media. This handling loss should be factored into any process yield calculations.

Making the Right Choice for Your Process

Your specific goal will determine which aspects of the removal process you prioritize.

- If your primary focus is maximizing product yield: Use brushes and spatulas to meticulously clean all surfaces, and consider a final solvent rinse (if compatible with your material) to capture every last particle.

- If your primary focus is speed and high throughput: Employ a large sieve over a wide collection pan to quickly separate the bulk of the material in a single pour.

- If your primary focus is purity and operator safety: Conduct the entire removal and separation process within a controlled environment, such as a glove box or a dedicated fume hood with dust collection.

A well-executed removal process is the final, critical step that validates the quality of your milling work and ensures a safe operating environment.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Safe Shutdown | Stop the machine, allow jar to rest. | Reduces dust, ensures safety. |

| 2. Opening the Jar | Unclamp lid in a ventilated area/fume hood. | Contains airborne particles. |

| 3. Separation | Pour contents through a sieve (dry) or decant liquid (wet). | Separates powder from grinding media. |

| 4. Final Recovery | Use brushes/spatulas to clean jar and media. | Maximizes product yield. |

Maximize the efficiency and safety of your milling process with the right equipment. KINTEK specializes in high-quality ball mills, durable grinding jars and media, and safety accessories designed for laboratory needs. Our experts can help you select the perfect setup for your materials to ensure optimal recovery and purity. Contact us today to discuss your specific application and enhance your lab's capabilities!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- Why is a laboratory ball mill used in Co-Ni catalyst research? Optimize CO2 Conversion with Precise Milling

- What role does a planetary ball mill play in eggshell fertilizer production? Unlock Superior Chemical Reactivity

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding

- Why use ball milling for NMC cathode materials? Achieve Precision Particle Sizing for Composite Cathodes

- What are the disadvantages of a ball mill? High Energy Use, Noise, and Contamination Risks