At its core, a ball mill grinds material by rotating a cylinder filled with grinding media, typically steel or ceramic balls. As the cylinder tumbles, the balls are lifted and then drop, crushing the material through impact. Simultaneously, the cascading and rubbing motion of the balls against each other and the material causes attrition, further reducing particle size.

A ball mill's effectiveness is not random; it is the controlled application of two distinct physical forces—impact and attrition. Mastering the balance between these forces by adjusting rotational speed, media size, and material load is the key to achieving a specific and consistent final product.

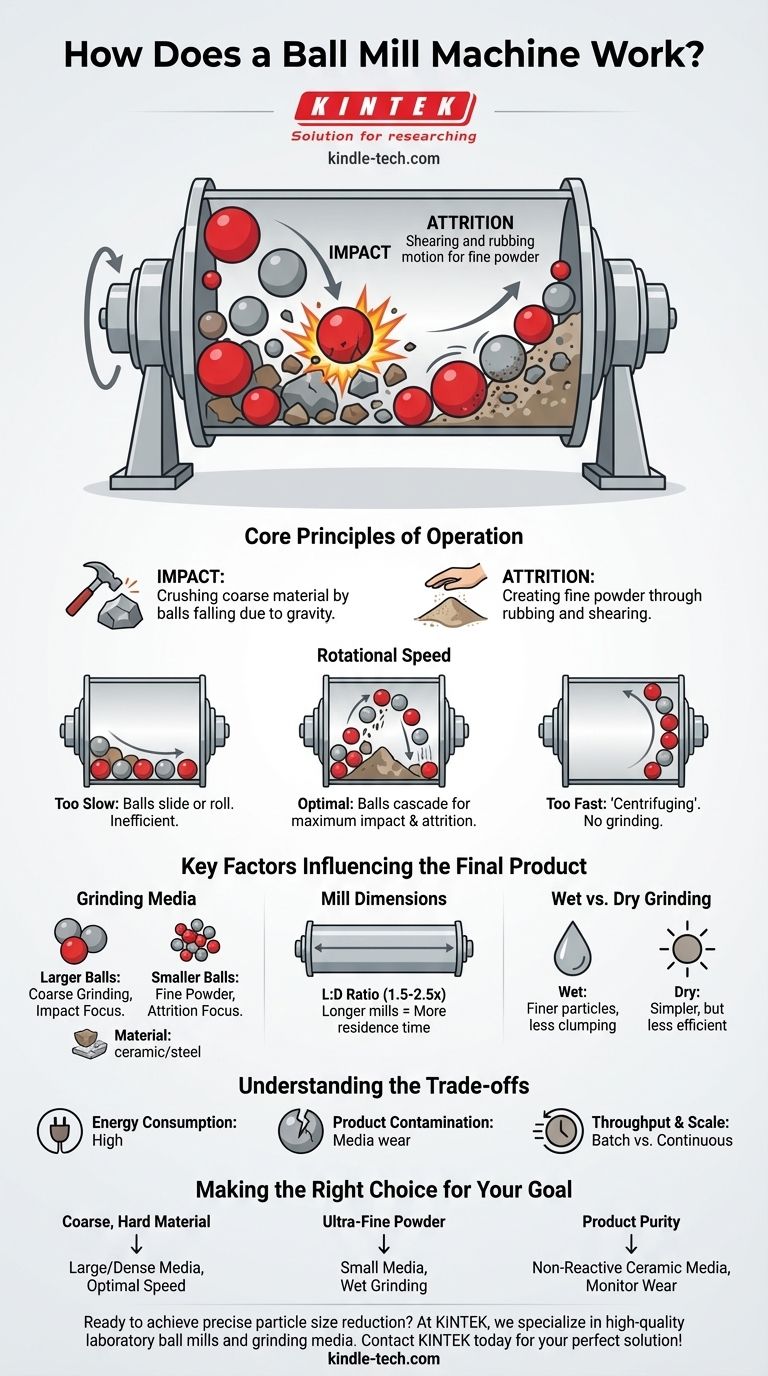

The Core Principles of Operation

A ball mill may seem like a simple brute-force instrument, but its operation is governed by precise mechanical principles. Understanding these is crucial for controlling the outcome.

The Grinding Mechanism: Impact

The primary force for breaking down coarse materials is impact. As the mill's drum rotates, it lifts the grinding balls up the side of the cylinder. Once they reach a certain height, gravity overcomes the centrifugal force, and the balls fall, striking the material below with significant force.

This action is similar to repeatedly striking a rock with a hammer, causing fractures and breaking large pieces into smaller ones.

The Grinding Mechanism: Attrition

The secondary force, attrition, is responsible for producing very fine powders. Attrition occurs as the balls cascade over one another, creating a shearing and rubbing action.

This constant friction grinds the particles down, smoothing their surfaces and reducing them to the desired fineness. This force is most prominent when smaller grinding media are used, as they provide a much greater surface area for rubbing.

The Critical Role of Rotational Speed

The speed of the drum is the single most important operational parameter.

- Too Slow: If the speed is too low, the balls will simply slide or roll down the inside of the drum. This generates some attrition but almost no impact, making the process highly inefficient for breaking larger particles.

- Too Fast: If the speed is too high, centrifugal force will pin the balls to the wall of the drum. This is known as "centrifuging," and it results in almost no relative motion, stopping the grinding process entirely.

- Optimal Speed: The ideal speed allows the balls to be carried almost to the top of the drum before cascading down, maximizing the impact energy while still allowing for attrition.

Key Factors Influencing the Final Product

Beyond the core principles, several factors determine the efficiency and outcome of the milling process.

Grinding Media Characteristics

The balls themselves are a critical variable. Larger, heavier balls are more effective at breaking down coarse feed materials through impact. Smaller balls are used to create finer products, as they fill the voids between larger balls and increase the total surface area available for attrition.

The material of the media—typically steel, ceramic, or stone—is chosen based on the required density, hardness, and potential for product contamination.

Mill Dimensions

Ball mills are often characterized by a length that is 1.5 to 2.5 times their diameter. This elongated design ensures that material fed into one end has sufficient "residence time" inside the mill to be ground to the required fineness before it exits the other end in a continuous system.

Wet vs. Dry Grinding

The process can be performed dry or wet (in suspension). Dry grinding is simpler, but wet grinding can increase efficiency, reduce energy consumption, and allow for the production of even finer particles by preventing powders from clumping.

Understanding the Trade-offs

While powerful, ball mills are not without limitations. A clear-eyed view of their trade-offs is essential.

Energy Consumption

Ball mills are energy-intensive machines. A significant amount of power is required to rotate the heavy drum and its charge of media and material. This operational cost is a major consideration for large-scale industrial applications.

Product Contamination

The constant impact and attrition cause the grinding media to wear down over time. This wear introduces a small amount of the media's material into the final product. For high-purity applications, such as pharmaceuticals or certain ceramics, this contamination can be a critical issue.

Throughput and Scale

Ball mills can operate in batch mode (loading, running, and emptying for each job) or continuous mode (a constant feed and discharge). While continuous operation allows for high throughput, the overall process can be slower compared to other grinding methods like hammer mills, which use high-speed direct impact.

Making the Right Choice for Your Goal

Your grinding strategy should be directly aligned with your end goal. Use these principles to guide your decision-making.

- If your primary focus is breaking down coarse, hard materials: Prioritize large, dense grinding media to maximize impact forces in a mill running at optimal speed.

- If your primary focus is producing an ultra-fine powder: Use a charge of smaller grinding media to maximize surface area and attrition, and consider wet grinding to prevent agglomeration.

- If your primary focus is product purity: Select non-reactive ceramic grinding media and closely monitor wear rates to minimize contamination.

By understanding these fundamental variables, you can effectively engineer the ball milling process to achieve your specific material-processing objectives.

Summary Table:

| Key Factor | Role in the Grinding Process | Effect on Final Product |

|---|---|---|

| Rotational Speed | Determines the cascade of grinding balls | Too slow: inefficient. Too fast: no grinding. Optimal: maximizes impact & attrition. |

| Grinding Media (Balls) | The tools that deliver impact and attrition forces | Larger balls: coarse grinding. Smaller balls: fine powder. Material affects purity. |

| Wet vs. Dry Grinding | The environment in which grinding occurs | Wet: finer particles, less agglomeration. Dry: simpler setup. |

| Mill Dimensions (L:D Ratio) | Controls the material's residence time | Longer mills (continuous) allow for more complete grinding of the feed material. |

Ready to achieve precise particle size reduction in your lab? The principles of impact and attrition are key to an effective ball milling process. At KINTEK, we specialize in providing high-quality laboratory ball mills and grinding media tailored to your specific application—whether you need to break down coarse materials or produce ultra-fine powders with high purity. Our experts can help you select the right equipment to optimize your grinding strategy and improve your lab's efficiency.

Contact KINTELK today to discuss your laboratory grinding needs and find the perfect ball mill solution for you!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Hybrid High Energy Vibratory Ball Mill for Lab Use

People Also Ask

- Why use ball milling for NMC cathode materials? Achieve Precision Particle Sizing for Composite Cathodes

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification

- What is the function of ball milling equipment in NZSSP electrolyte preparation? Optimize NASICON Solid-State Synthesis

- What is the product size of a ball mill? Achieve Micron-Level Precision for Your Materials

- What role does a planetary ball mill play in eggshell fertilizer production? Unlock Superior Chemical Reactivity