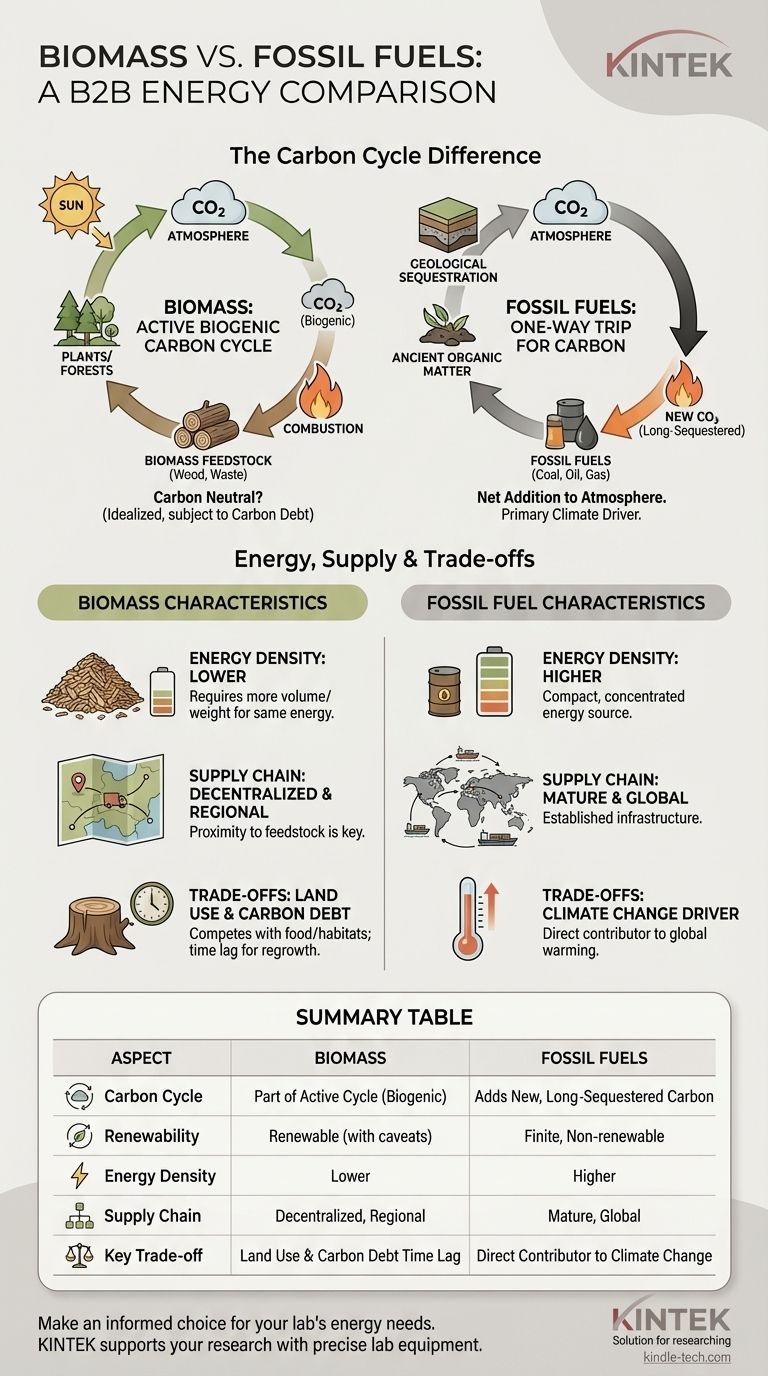

At its core, biomass is a renewable energy source derived from organic matter like plants and wood, while fossil fuels are finite energy sources like coal, oil, and natural gas formed from ancient organic matter over millions of years. While both release carbon dioxide when burned, biomass releases carbon that is part of the active biogenic carbon cycle, whereas fossil fuels release ancient, long-sequestered carbon into the atmosphere. This fundamental difference is the source of both the primary benefit and the primary controversy surrounding biomass energy.

The central distinction is not simply "renewable vs. non-renewable." It's understanding that while fossil fuels add new carbon to the atmosphere, biomass operates within the current carbon cycle—a fact with complex consequences for land use, "carbon debt," and the technology's true climate impact.

The Fundamental Difference: The Carbon Cycle

To compare these fuels, we must first understand how they interact with the global carbon system. This is the most critical point of distinction.

Fossil Fuels: A One-Way Trip for Carbon

Fossil fuels are the product of immense heat and pressure acting on organic matter buried for hundreds of millions of years. This process locked vast quantities of carbon deep underground, effectively removing it from the active atmosphere.

When we burn coal, oil, or natural gas, we are taking this long-sequestered carbon and releasing it in a geological instant. This is a net addition of carbon to the modern atmosphere and the primary driver of anthropogenic climate change.

Biomass: A Role in the Active Carbon Cycle

Biomass energy comes from organic material that is living or was recently living. This includes everything from forestry residues and agricultural crops to municipal solid waste.

The carbon released when biomass is burned is biogenic carbon. This is carbon that was recently absorbed from the atmosphere by plants through photosynthesis. In theory, if the harvested biomass is replaced by new growth at the same rate, the process is considered part of a closed loop.

The "Carbon Neutrality" Debate

The idea that biomass is "carbon neutral" is an oversimplification. This concept is true only under specific and often idealized conditions.

Burning biomass releases CO2 immediately, but it takes time for new plants or trees to grow and re-absorb that same amount of carbon. This time lag creates a "carbon debt." The length of this debt—from years for grasses to decades or even centuries for forests—is a major point of contention and depends entirely on the type of biomass used.

Comparing Energy, Efficiency, and Logistics

Beyond the carbon cycle, practical considerations like energy output and infrastructure are crucial for any real-world application.

Energy Density: Fossil Fuels' Key Advantage

Energy density refers to the amount of energy stored in a given volume or mass of fuel. In this area, fossil fuels are the clear winners.

A small amount of oil, coal, or natural gas contains a massive amount of concentrated energy. Biomass, which often has high moisture content, is far less energy-dense. This means you need significantly more biomass by weight and volume to produce the same amount of energy, which has major implications for transportation, storage, and handling.

Feedstock and Supply Chain

Fossil fuels benefit from a mature, global infrastructure for extraction, processing, and distribution that has been optimized for over a century.

The biomass supply chain is, by contrast, highly decentralized and regional. It depends on proximity to forests, farms, or waste processing facilities. This can be an advantage for local energy independence but a challenge for large-scale, consistent power generation.

Understanding the Trade-offs

Neither energy source is without significant downsides. A trusted evaluation requires an objective look at the costs of each.

Land Use and Biodiversity

This is perhaps the most significant trade-off for biomass. Dedicating vast tracts of land to growing energy crops can compete with food production, drive up prices, and lead to deforestation and habitat loss if not managed with extreme care.

While fossil fuel extraction (like mountaintop removal or oil spills) has a severe and concentrated environmental impact, its direct land footprint for a given unit of energy is typically smaller than that required for purpose-grown biomass.

Other Emissions

Combustion is never perfectly clean. Burning biomass can release nitrogen oxides (NOx), volatile organic compounds (VOCs), and particulate matter, which are air pollutants that can impact human health.

While modern biomass plants use scrubbers and filters, just as new coal plants do, the emission profile depends heavily on the feedstock and combustion technology. It is not inherently "cleaner" than natural gas, which burns with far fewer pollutants.

Cost and Scalability

Historically, fossil fuels have been a cheap and scalable source of on-demand power. However, this is changing as the costs of renewable alternatives fall and the "external" costs of carbon emissions (climate impact, health effects) are increasingly priced in through regulation.

Biomass can be cost-effective when using waste streams (e.g., sawmill residue, manure) but becomes much more expensive when crops are grown specifically for energy. Its scalability is ultimately limited by sustainable land and water availability.

Making the Right Choice for Your Goal

The decision to use biomass or fossil fuels depends entirely on the strategic objective. The context of the application determines its value.

- If your primary focus is leveraging local waste streams: Biomass is an excellent solution for converting agricultural, forestry, or municipal waste into a valuable source of local heat and power.

- If your primary focus is rapid, large-scale decarbonization: Biomass can serve as a transitional fuel by replacing coal in existing power plants (co-firing), but its scalability is a major constraint, and it cannot be the sole pillar of a low-carbon grid.

- If your primary focus is a zero-impact energy source: Neither fits this description. Fossil fuels add new carbon and have high extraction impacts, while biomass has significant land-use, water, and "carbon debt" implications that must be managed.

Ultimately, evaluating energy sources requires moving beyond simple labels to a nuanced assessment of the specific feedstock, technology, and strategic purpose.

Summary Table:

| Aspect | Biomass | Fossil Fuels |

|---|---|---|

| Carbon Cycle | Part of active cycle (biogenic carbon) | Adds new, long-sequestered carbon |

| Renewability | Renewable (with caveats) | Finite, non-renewable |

| Energy Density | Lower | Higher |

| Supply Chain | Decentralized, regional | Mature, global |

| Key Trade-off | Land use & carbon debt time lag | Direct contributor to climate change |

Make an informed choice for your lab's energy needs. The debate between biomass and fossil fuels is complex, requiring a nuanced understanding of carbon cycles, efficiency, and sustainability. At KINTEK, we specialize in providing the precise lab equipment and consumables you need to conduct your own energy research and analysis. Whether you're evaluating biofuels or optimizing combustion processes, our solutions support accurate, reliable data generation.

Let KINTEK empower your research. Contact our experts today to discuss how our products can help you navigate the complexities of energy sources and achieve your sustainability goals.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

People Also Ask

- What role does an autoclave play in simulating PWR conditions? Advanced Material Validation for Nuclear Safety

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation