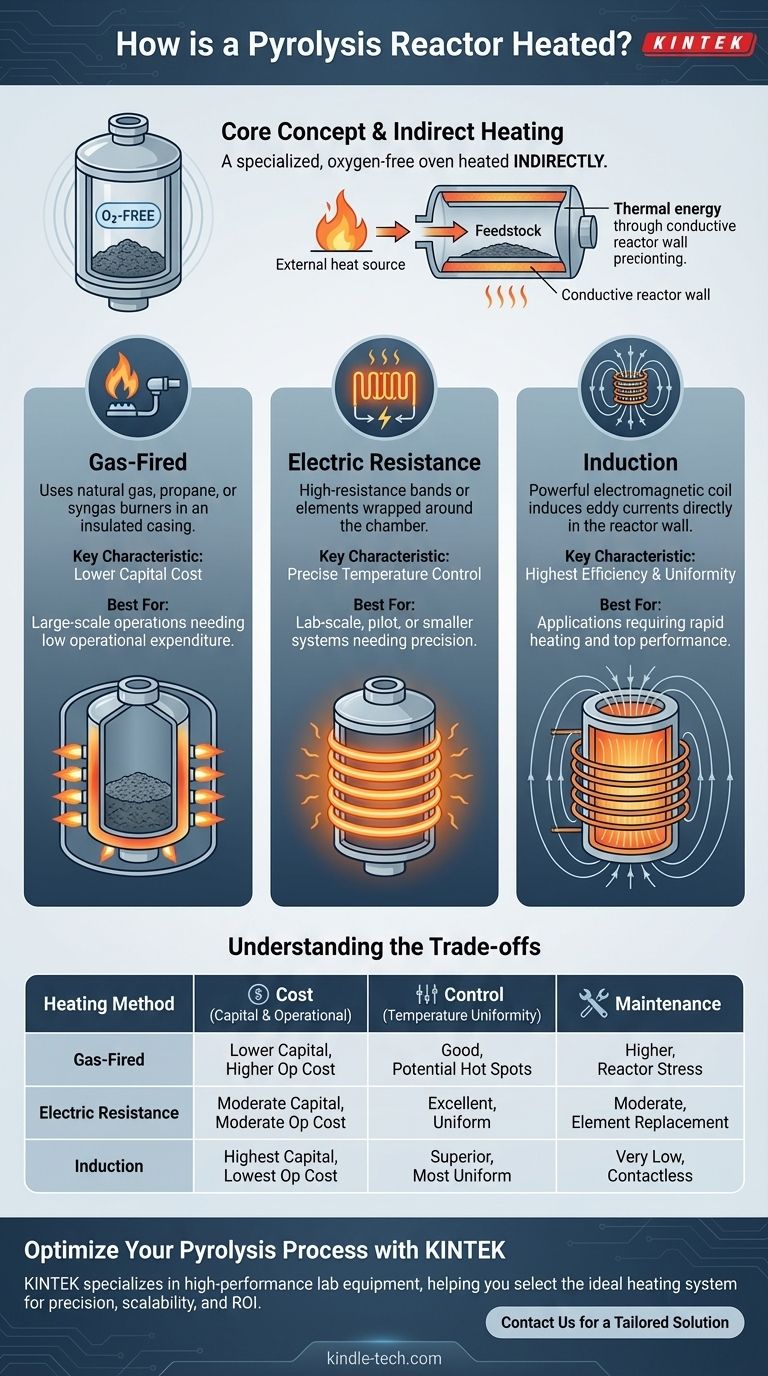

At its core, a pyrolysis reactor is a specialized, oxygen-free oven, and the method used to heat it is a critical design choice. The most common heating technologies are gas-fired burners, electric resistance elements, and electromagnetic induction. The selection of a specific method is not arbitrary; it is a calculated decision based on the desired processing speed, temperature precision, and the economics of the entire system.

The fundamental challenge in heating a pyrolysis reactor is not simply reaching a high temperature, but delivering that heat uniformly and efficiently through the reactor wall to the feedstock inside, all while maintaining an oxygen-free environment.

The Principle of Indirect Heating

Nearly all pyrolysis reactors rely on indirect heating. This is a crucial concept to grasp.

Because pyrolysis must occur in the absence of oxygen to prevent combustion, you cannot simply light a fire inside the reaction chamber.

Instead, heat is generated externally and transferred to the feedstock through the conductive metal walls of the reactor. This preserves the anoxic conditions necessary for the chemical decomposition to occur correctly.

Common Heating Methods Explored

Each heating method represents a different approach to solving the indirect heating challenge, with distinct advantages and disadvantages.

Gas-Fired Heating

This is a traditional and widely used method, especially in large-scale industrial plants. It involves using a series of burners, fueled by natural gas, propane, or even recycled syngas from the pyrolysis process itself.

The burners are arranged within an insulated casing surrounding the reactor, heating its external surface. The heat then conducts through the steel to the feedstock.

Electric Resistance Heating

This method functions much like a common electric kiln or oven. High-resistance heating elements or bands are wrapped around the exterior of the reactor chamber.

When a high electrical current is passed through these elements, they heat up significantly, transferring radiant and conductive heat to the reactor wall. This approach is common in lab-scale, pilot, and smaller commercial systems where precision is key.

Induction Heating

Induction is the most technologically advanced of the three. It uses a powerful electromagnetic coil that generates a fluctuating magnetic field around the reactor.

This magnetic field induces electrical "eddy currents" directly within the conductive metal wall of the reactor itself. The resistance of the metal to these currents generates intense, rapid, and uniform heat from within the reactor wall.

Understanding the Trade-offs

Choosing a heating method involves a careful balance of cost, performance, and operational complexity.

Capital Cost vs. Operational Cost

There is a direct trade-off here. Gas-fired systems often have a lower capital cost but an operational cost tied to fluctuating fuel prices.

Electric resistance systems have a moderate capital cost, but their operational cost can be high depending on local electricity rates.

Induction heating carries the highest initial capital cost due to the complex power electronics required, but it is often the most energy-efficient, which can lower long-term operational costs.

Temperature Control and Uniformity

This is arguably the most critical factor for product quality. Inconsistent heating leads to an inconsistent product.

Gas-fired systems can struggle with uniformity, creating "hot spots" on the reactor surface that can lead to uneven pyrolysis and thermal stress on the metal.

Electric resistance offers very good temperature control and uniformity, as the elements can be zoned and managed precisely.

Induction heating provides the best performance, as the heat is generated evenly throughout the reactor wall itself, ensuring the most uniform temperature profile possible.

Reactor Material and Maintenance

The heating method directly impacts the reactor's lifespan. The thermal stress from hot spots in gas-fired systems often necessitates the use of more robust and expensive alloys like stainless steel (e.g., 304 or 310) over standard boiler plate.

Electric elements can burn out over time and require replacement. Induction coils operate at low temperatures and are contactless, leading to very low maintenance requirements for the heating system itself.

Making the Right Choice for Your System

Your final decision will be dictated by the primary goal of your pyrolysis operation.

- If your primary focus is precise process control and consistent product quality: Electric resistance or induction heating offers the best temperature uniformity and responsiveness.

- If your primary focus is minimizing operational expenditure at industrial scale: Gas-fired heating, especially when using recycled process gas as fuel, is often the most economical choice.

- If your primary focus is rapid heating cycles and maximum energy efficiency: Induction heating is superior, though it comes with the highest initial capital investment.

Ultimately, the heating system is the engine of the reactor, and its selection determines the performance, efficiency, and economic viability of the entire process.

Summary Table:

| Heating Method | Key Characteristic | Best For |

|---|---|---|

| Gas-Fired | Lower capital cost, uses fuel burners | Large-scale operations minimizing operational costs |

| Electric Resistance | Precise temperature control, moderate cost | Lab-scale or smaller commercial systems needing precision |

| Induction | Highest efficiency and uniformity, rapid heating | Applications requiring top performance and energy savings |

Optimize Your Pyrolysis Process with KINTEK

Choosing the right heating method is critical to the success and efficiency of your pyrolysis operation. The wrong choice can lead to inconsistent product quality, high operational costs, and frequent maintenance.

KINTEK specializes in high-performance lab equipment and consumables. Our expertise can help you select the ideal pyrolysis reactor heating system for your specific needs, whether you prioritize precision, scalability, or cost-effectiveness.

Contact us today using the form below to discuss your project requirements. Let our experts provide a tailored solution that ensures uniform heating, maximizes your ROI, and enhances your lab's capabilities.

Visual Guide

Related Products

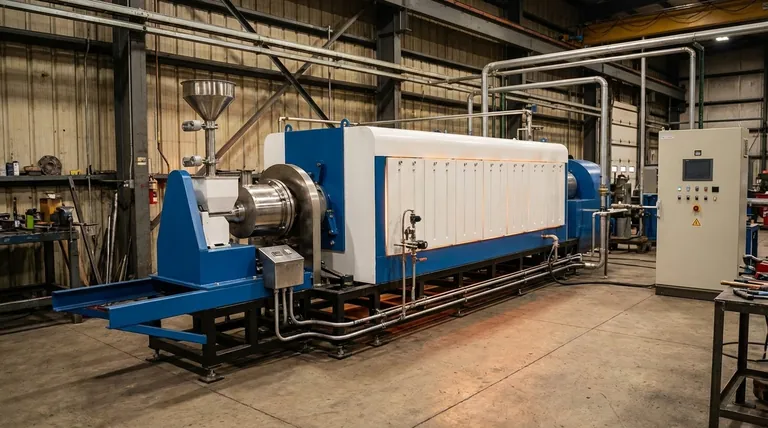

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs