At its core, hot isostatic pressing (HIP) is a material processing method that uses a combination of high temperature and immense, uniform pressure to densify materials and eliminate internal defects. A component or powdered metal is first sealed in a container, which is then placed inside a high-pressure vessel. An inert gas, typically Argon, is used to apply uniform pressure from all directions while the vessel is heated, consolidating the material into a solid, fully dense state.

The central concept of HIP is not just pressing, but a sophisticated thermal treatment. It uses inert gas as a perfectly uniform pressure medium to heat and squeeze materials simultaneously, closing microscopic voids and creating components with properties that are impossible to achieve through conventional casting or forging alone.

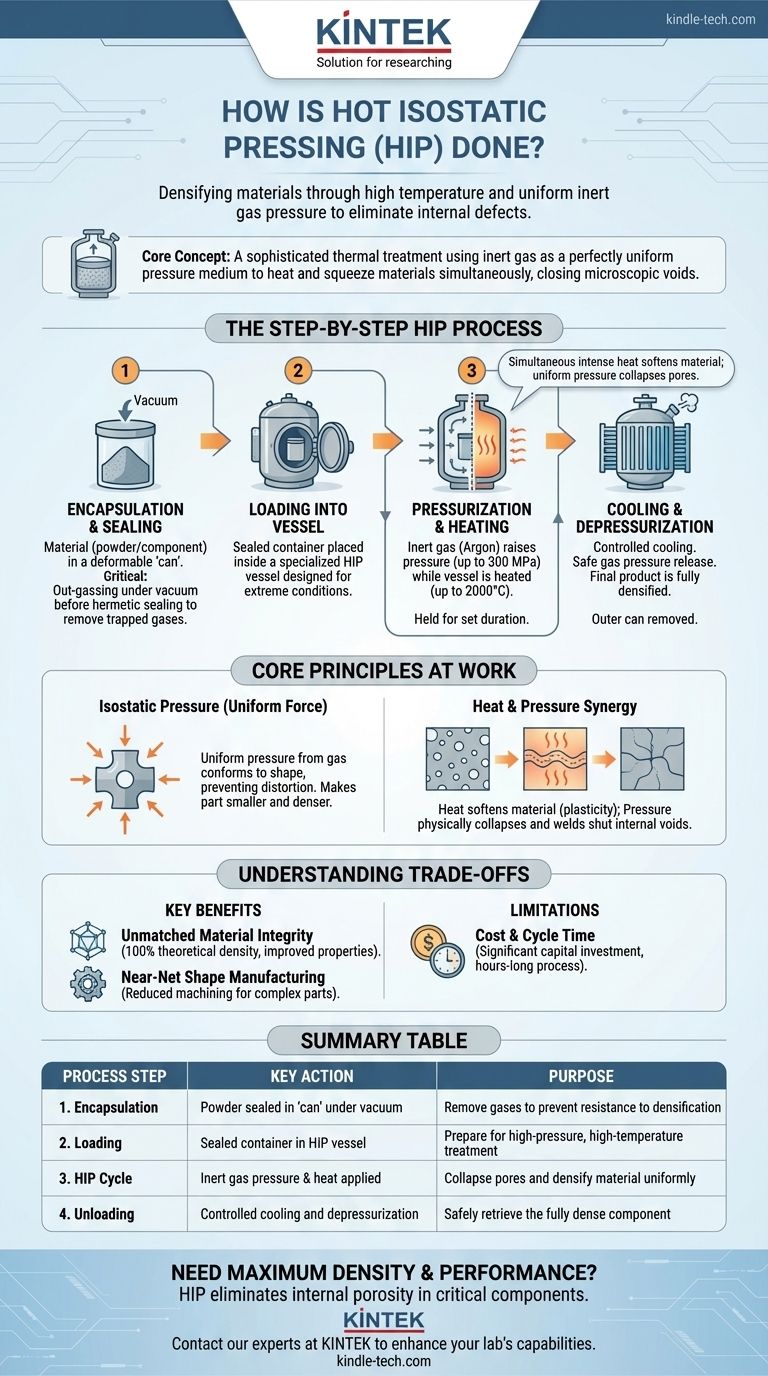

The Step-by-Step HIP Process

Understanding how hot isostatic pressing is performed involves a few precise and critical stages, from preparation to the final dense product.

Step 1: Encapsulation and Sealing

Before the process begins, the material—often a metal or ceramic powder—is placed into a specially designed container, sometimes called a "can." This can is typically made of a metal or glass that will deform under pressure.

The most critical part of this step is out-gassing. The container is placed under a vacuum to remove all air and other gases before being hermetically sealed. This prevents trapped gases from resisting the densification process.

Step 2: Loading into the HIP Vessel

The sealed container is then placed inside the chamber of a hot isostatic press. This is a specialized piece of equipment designed to safely handle extreme temperatures and pressures.

Step 3: Pressurization and Heating

The HIP vessel is sealed, and an inert gas, almost always Argon, is pumped into the chamber to raise the pressure. Inert gas is used because it will not chemically react with the material being processed, even at high temperatures.

Simultaneously, the vessel is heated. The combination of intense heat (up to 2000°C) and extreme pressure (up to 300 MPa or 45,000 psi) is applied for a set period.

Step 4: Cooling and Depressurization

After the material is held at the target temperature and pressure for a sufficient duration, the system is cooled in a controlled manner. Once cool, the gas pressure is safely released from the chamber.

The final product is a fully densified part. The outer can is then removed, typically through machining or chemical etching, revealing the finished component.

The Core Principles at Work

The effectiveness of HIP lies in the synergy of its core components: the gas, the heat, and the pressure. Each plays a distinct and crucial role.

The Role of Isostatic Pressure

The term "isostatic" means that the pressure is uniform and applied equally from all directions. A gas is the perfect medium for this, as it conforms to any shape and exerts consistent pressure on every surface of the component.

This uniformity is why HIP does not distort the part's shape, a major advantage over directional forging or pressing methods. It simply makes the part smaller and denser.

Why Both Heat and Pressure Are Essential

Heat serves to soften the material, making it more plastic and malleable on a microscopic level. This allows the material to flow and deform.

Pressure provides the driving force to physically collapse and weld shut any internal pores, voids, or micro-cracks. Without the high temperature, the pressure alone would not be enough to fully densify the material.

Understanding the Trade-offs

While powerful, hot isostatic pressing is a specialized process with specific considerations.

Key Benefit: Unmatched Material Integrity

The primary advantage of HIP is its ability to achieve 100% theoretical density. This elimination of internal porosity dramatically improves mechanical properties like fatigue life, toughness, and consistency, which is critical for high-performance applications like aerospace components or medical implants.

Key Benefit: Near-Net Shape Manufacturing

For powder metallurgy, HIP allows for the creation of complex, "near-net shape" parts. This minimizes the amount of final machining required, saving time and reducing waste of expensive advanced materials.

Limitation: Cost and Cycle Time

HIP equipment is a significant capital investment, and the process itself can take several hours from start to finish. This makes it more expensive than conventional manufacturing methods and best suited for high-value components where performance is non-negotiable.

Making the Right Choice for Your Goal

Hot isostatic pressing is not a universal solution, but it is an indispensable tool for achieving the highest level of material quality.

- If your primary focus is maximum density and performance: HIP is the definitive process for eliminating internal porosity in critical cast or 3D-printed components.

- If your primary focus is creating complex parts from advanced powders: HIP is an exceptional method for consolidating powders into fully dense components with uniform properties.

- If your primary focus is extending the life of critical parts: The process is often used to heal internal voids caused by fatigue or creep damage in components like industrial gas turbine blades.

Ultimately, hot isostatic pressing provides a powerful method for engineering materials to their absolute theoretical limits.

Summary Table:

| Process Step | Key Action | Purpose |

|---|---|---|

| 1. Encapsulation | Powder is sealed in a 'can' under vacuum | Remove gases to prevent resistance to densification |

| 2. Loading | Sealed container is placed in HIP vessel | Prepare for high-pressure, high-temperature treatment |

| 3. HIP Cycle | Inert gas pressure (up to 300 MPa) & heat (up to 2000°C) applied | Collapse pores and densify the material uniformly |

| 4. Unloading | Controlled cooling and depressurization | Safely retrieve the fully dense component |

Need to achieve maximum density and performance for your critical components? The HIP process is essential for eliminating internal porosity in castings, 3D-printed parts, and powder metallurgy. KINTEK specializes in advanced lab equipment and consumables for material processing. Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and help you engineer materials to their theoretical limits.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

People Also Ask

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process