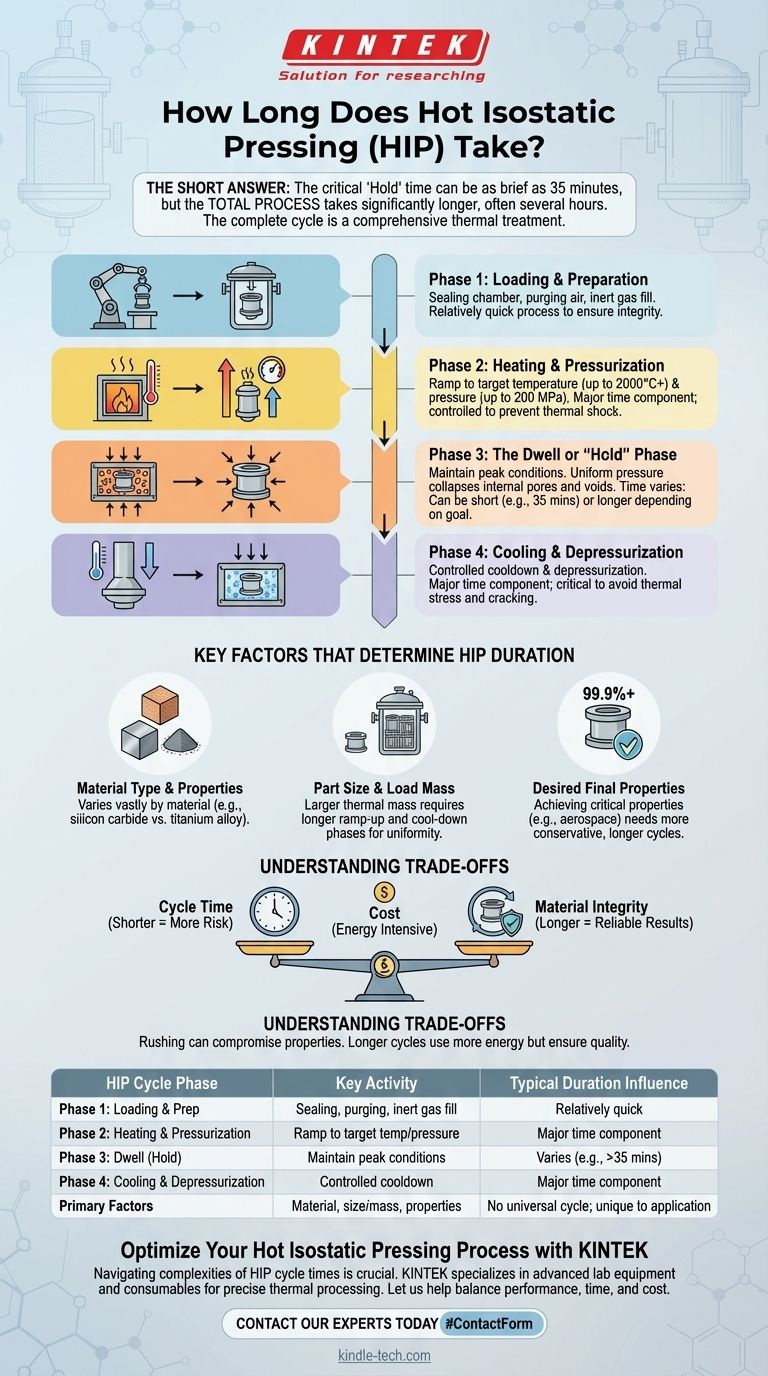

The short answer is that the critical "hold" time for hot isostatic pressing (HIP) can be as brief as 35 minutes for certain applications, but this is a misleadingly simple figure. The total process time, from loading the component to safely removing it, is significantly longer, often spanning several hours. The complete cycle includes extensive heating, pressurization, and cooling phases that are essential for a successful outcome.

The total duration of a hot isostatic pressing cycle is not a single number but a function of the entire process—heating, pressurizing, holding, and cooling. This full cycle time is dictated by the material type, the size and mass of the part, and the specific metallurgical goal.

Deconstructing the Total HIP Cycle Time

To understand how long hot isostatic pressing takes, you must look beyond the "hold" time and consider the four distinct phases of a complete cycle. The majority of the time is spent in the ramp-up and cool-down stages.

Phase 1: Loading and Preparation

This initial step involves placing the parts into the HIP vessel. The chamber is then sealed and purged of air, which is replaced with an inert gas, typically argon. This phase is relatively quick but critical for process integrity.

Phase 2: Heating and Pressurization

This is a significant portion of the total cycle time. The vessel and the parts within it are slowly heated to a specific sintering temperature, which can range from a few hundred to over 2,000°C.

Simultaneously, the inert gas is pressurized, often up to 200 MPa (nearly 30,000 psi). This ramp-up must be carefully controlled to ensure the part heats uniformly, preventing thermal shock or internal stress.

Phase 3: The Dwell or "Hold" Phase

This is the phase most people ask about. During this period, the part is held at the peak temperature and pressure. The uniform, isostatic pressure collapses internal pores and voids, increasing the component's density.

The duration of this hold is determined by the material and the goal. It might be short for closing micro-porosity in a casting or longer for diffusion bonding dissimilar materials together.

Phase 4: Cooling and Depressurization

Once the dwell time is complete, the cycle enters a controlled cool-down and depressurization phase. Like the heating phase, this cannot be rushed.

Rapid cooling can induce thermal stress, cause cracking, or result in an undesirable final material structure. The larger and more massive the part, the longer this controlled cooling process will take.

Key Factors That Determine HIP Duration

There is no universal HIP cycle time because the process is tailored to the specific application. The total duration is a direct result of three primary factors.

Material Type and Properties

Different materials require vastly different parameters. For example, densifying a silicon carbide powder requires a specific temperature and pressure profile that is completely different from that needed to densify a 3D-printed titanium alloy.

Part Size and Load Mass

A small, single component will heat and cool much faster than a large vessel loaded with hundreds of pounds of parts. The larger the thermal mass, the longer the ramp-up and cool-down phases must be to ensure temperature is uniform throughout the entire load.

Desired Final Properties

The end goal dictates the process. Achieving 99.9%+ theoretical density in a critical aerospace component will require a more conservative and typically longer cycle than a less demanding commercial application. The process is optimized to achieve specific metallurgical properties, and time is a key variable in that equation.

Understanding the Trade-offs

Optimizing a HIP cycle is a balance of performance, time, and cost. Understanding the interplay between these factors is crucial for making sound engineering and business decisions.

Time vs. Material Integrity

Rushing the cycle is a false economy. Heating or cooling too quickly can create internal stresses that compromise the part's mechanical properties or even cause it to fail. The most reliable results come from slow, highly controlled thermal cycles.

Cost vs. Cycle Time

HIP is an energy-intensive process. The equipment is expensive to run, and longer cycles consume more electricity and inert gas. Therefore, there is always a commercial incentive to shorten cycle times, but this must be balanced against the risk of producing a substandard part.

The Myth of a "Standard" Cycle

Because every combination of material, part geometry, and performance goal is unique, there is no "standard" HIP time. Each application requires a carefully developed and validated cycle to ensure repeatable, high-quality results.

Making the Right Choice for Your Application

To estimate the time required for your project, consider the primary objective of the HIP treatment.

- If your primary focus is closing porosity in metal castings or 3D prints: Expect a total cycle time of several hours, with the majority of time spent on carefully controlled heating and cooling to ensure uniform density and prevent distortion.

- If your primary focus is applying a dense ceramic coating: The hold time at peak temperature may be relatively short (e.g., under an hour), but the full cycle will still be significantly longer due to the thermal requirements of the substrate material.

- If your primary focus is diffusion bonding dissimilar materials: The hold time will be highly specific to the materials' atomic diffusion rates and may require extensive development, often resulting in longer cycles to guarantee a robust bond.

Ultimately, understanding that HIP is a comprehensive thermal treatment, not just a simple pressure application, is the key to planning your manufacturing process effectively.

Summary Table:

| HIP Cycle Phase | Key Activity | Typical Duration Influence |

|---|---|---|

| Phase 1: Loading & Prep | Sealing chamber, purging air, inert gas fill | Relatively quick |

| Phase 2: Heating & Pressurization | Ramp to target temperature (up to 2000°C+) and pressure (up to 200 MPa) | Major time component; must be controlled to prevent stress |

| Phase 3: Dwell (Hold) | Maintain peak temperature/pressure to densify material | Can be as short as 35 minutes; varies with application goal |

| Phase 4: Cooling & Depressurization | Controlled cooldown to room temperature and pressure | Major time component; critical to avoid cracking |

| Primary Factors Affecting Total Time | Material type, part size/mass, desired final properties | No universal cycle; each application is unique |

Optimize Your Hot Isostatic Pressing Process with KINTEK

Navigating the complexities of HIP cycle times is crucial for achieving the material integrity and density your critical components demand. KINTEK specializes in providing the advanced lab equipment and consumables necessary for precise thermal processing. Whether you are working with metal castings, 3D-printed alloys, or ceramics, our expertise ensures you have the right tools to develop and validate efficient, effective HIP cycles.

Let us help you balance performance, time, and cost to achieve 99.9%+ theoretical density and superior mechanical properties. Contact our experts today to discuss your specific application and how our solutions can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the primary function of an industrial Hot Isostatic Press (HIP)? Maximize Powder Alloy Densification Today

- What are the advantages of hot isostatic pressing? Achieve Unmatched Material Integrity & Performance

- How does Hot Isostatic Pressing (HIP) enhance CuNiCoZnAlTi properties? Achieve Theoretical Density & Maximum Strength

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- What is the HIP sintering process? Achieve Near-Perfect Densification for Critical Components

- What is the hot isostatic process? Achieve Perfect Material Density for Critical Components

- What is the primary function of Hot Isostatic Pressing (HIP) equipment? Achieve Peak Density in IN718 Superalloys

- What is the hot isostatic pressing cycle? A Guide to HIP for Superior Material Integrity