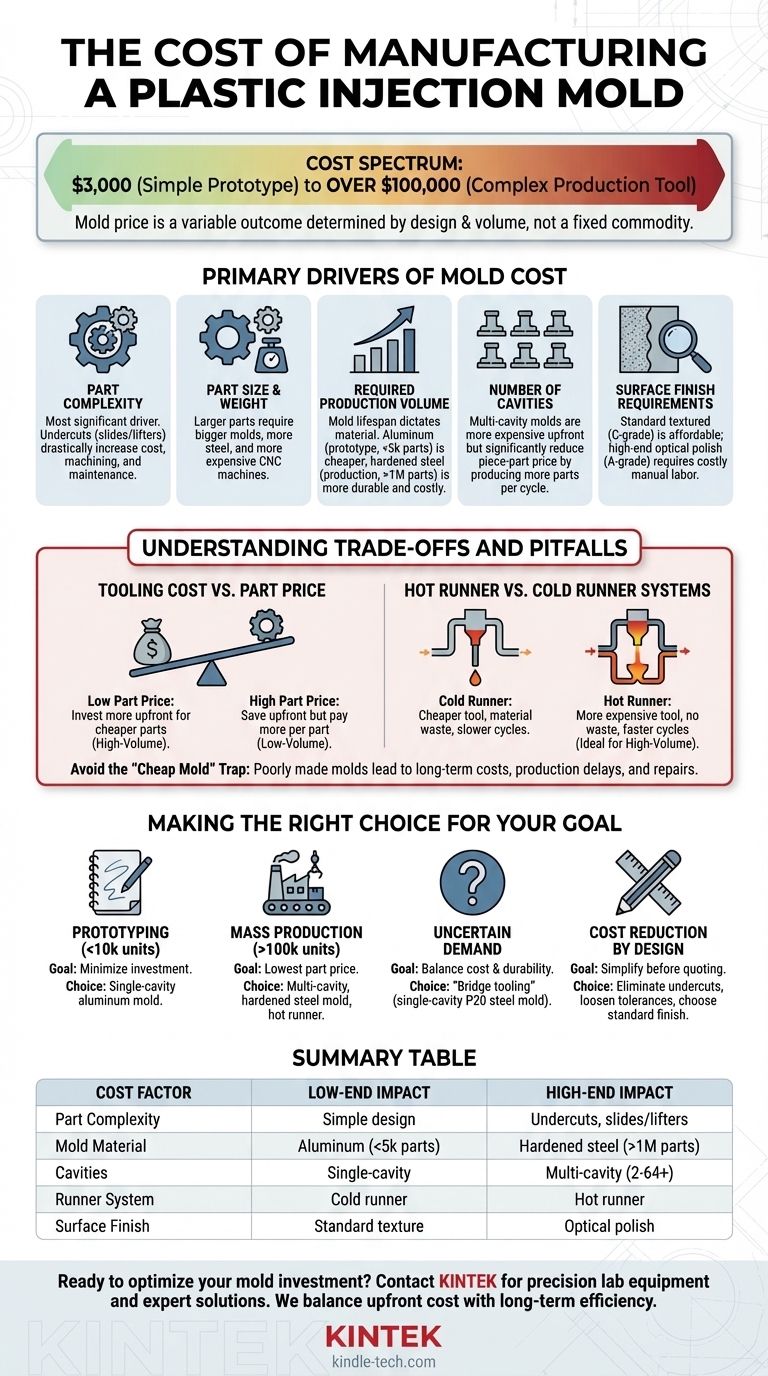

The cost to manufacture a plastic injection mold is not a single number but a wide spectrum, typically ranging from $3,000 for a simple prototype tool to well over $100,000 for a complex, high-volume production tool. This vast range exists because a mold is not a commodity; it is a piece of custom-engineered industrial machinery, and its price is a direct reflection of the design of the part it is intended to produce and the volume of parts it is built to withstand.

The price of an injection mold is not a fixed cost to be discovered, but a variable outcome that you can control. The final cost is determined by a handful of key factors—primarily part complexity, production volume, and material choice—and understanding them is the key to optimizing your budget.

The Primary Drivers of Mold Cost

A mold's cost is a direct function of the time, materials, and precision required to build it. Every design decision you make for your part has a direct and tangible impact on the final tooling price.

Part Complexity

This is the single most significant cost driver. A simple, open-and-shut part is far cheaper to tool than one with intricate features.

Key features that add cost include undercuts, which are details that prevent the part from being ejected directly from the mold. These require mechanical slides or lifters to be built into the tool, dramatically increasing machining time, assembly, and maintenance complexity.

Part Size and Weight

Larger parts require larger molds. This means more steel must be purchased, and the machining time on larger CNC machines is more expensive. A larger part also necessitates a larger, more expensive injection molding press to run it.

Required Production Volume (Mold Lifespan)

The total number of parts you plan to produce dictates the material used for the mold, which has a massive impact on cost.

A prototype mold intended for 5,000 parts can be made from aluminum. It's faster to machine and thus cheaper, but it wears out quickly. A production mold built for over 1,000,000 parts requires hardened tool steel (like P20 or H13), which is much more durable but also significantly more expensive and time-consuming to machine.

Number of Cavities

A mold can be built with a single cavity (producing one part per cycle) or multiple cavities (producing 2, 4, 8, or even 64 parts per cycle).

A multi-cavity mold is much more expensive to build upfront due to the multiplied complexity. However, it dramatically reduces the piece-part price because you produce more parts in the same amount of time.

Surface Finish Requirements

A textured or matte finish (known as a C-grade SPI finish) is the standard and most affordable option.

If your part requires a semi-gloss (B-grade) or mirror-like optical polish (A-grade), the cost will increase substantially. This level of finish requires many hours of highly skilled manual labor for hand-polishing the steel cavities.

Understanding the Trade-offs and Pitfalls

Choosing a mold manufacturer solely on the lowest bid can be a costly mistake. The initial tooling price is only one part of the total cost equation.

Tooling Cost vs. Part Price

There is an inverse relationship here. Investing more in a high-quality, multi-cavity mold will lead to a higher upfront tooling bill but a lower cost for each individual part produced.

Conversely, saving money on a cheap, single-cavity mold will result in a higher part price, which can eliminate your profit margin on a high-volume product.

Hot Runner vs. Cold Runner Systems

A cold runner is the simplest system, where the plastic path from the nozzle to the part solidifies with the part and is ejected as waste. The tool is cheaper, but you waste material and have a slightly longer cycle time.

A hot runner system keeps the plastic molten all the way to the part, eliminating waste and enabling faster cycles. The tool is significantly more expensive and complex, but the savings on material and cycle time can be immense for high-volume production.

The "Cheap Mold" Trap

A poorly made mold, even if it's cheap, will cost you more in the long run. Issues like inefficient cooling channels lead to longer cycle times, increasing your part price.

Furthermore, a low-quality tool is prone to breaking down, causing expensive production delays and repair costs. The total cost of ownership is what matters, not just the initial purchase price.

Geographic Sourcing (Domestic vs. Overseas)

Sourcing a mold from a region like China can often result in a lower initial price tag due to lower labor costs. However, this must be weighed against potential challenges in communication, longer shipping times, logistics complexity, and difficulties in making quick tool modifications.

Domestic sourcing typically offers faster turnaround, easier communication, and stronger IP protection, but at a higher upfront cost.

Making the Right Choice for Your Goal

The "right" mold cost is the one that aligns with your business objectives. Instead of asking for a price, define your goal and build the tool to match it.

- If your primary focus is prototyping or low-volume runs (< 10,000 units): Opt for a single-cavity aluminum mold to minimize your initial investment and validate your design quickly.

- If your primary focus is mass production and lowest part price (> 100,000 units): Invest in a multi-cavity, hardened steel mold, likely with a hot runner system, to optimize for efficiency and longevity.

- If your primary focus is launching a new product with uncertain demand: Consider "bridge tooling"—a single-cavity P20 steel mold that offers a balance of durability and moderate cost before committing to expensive multi-cavity tools.

- If your primary focus is reducing cost through design: Simplify your part to eliminate undercuts, loosen non-critical tolerances, and choose a standard finish before you ever request a quote from a mold maker.

By understanding these fundamental drivers, you shift from simply asking "what does it cost?" to actively controlling the cost of your manufacturing.

Summary Table:

| Cost Factor | Low-End Impact | High-End Impact |

|---|---|---|

| Part Complexity | Simple, open-and-shut design | Undercuts requiring slides/lifters |

| Mold Material | Aluminum (prototype, <5k parts) | Hardened steel (production, >1M parts) |

| Cavities | Single-cavity mold | Multi-cavity mold (2-64+) |

| Runner System | Cold runner (cheaper tooling) | Hot runner (faster cycles, less waste) |

| Surface Finish | Standard texture (C-grade SPI) | Optical polish (A-grade SPI) |

Ready to optimize your mold investment? At KINTEK, we specialize in precision lab equipment and consumables for manufacturing. Our experts can help you navigate the complexities of mold design to balance upfront cost with long-term production efficiency. Whether you need prototyping tools or high-volume production molds, we provide solutions tailored to your laboratory and manufacturing needs. Contact us today for a consultation and let's build the right tool for your success.

Visual Guide

Related Products

- Special Shape Press Mold for Lab

- Polygon Press Mold for Lab

- Ball Press Mold for Lab

- Assemble Lab Cylindrical Press Mold

- Cylindrical Press Mold with Scale for Lab

People Also Ask

- What role do customized metal molds play in solid-state battery densification? Achieving Precision at 500 MPa

- Why are high-strength graphite molds essential for vacuum hot pressing? Optimize Your Diamond/Copper Composites

- What are the advantages of using high-strength graphite molds in the hot press sintering of Ti6Al4V-based composites?

- What technical requirements must specialized pressure-bearing molds meet? Optimize Sulfide Electrolyte Densification

- How does a stainless steel pressure die ensure the quality of the electrolyte layer? Unlock Precision Battery Assembly