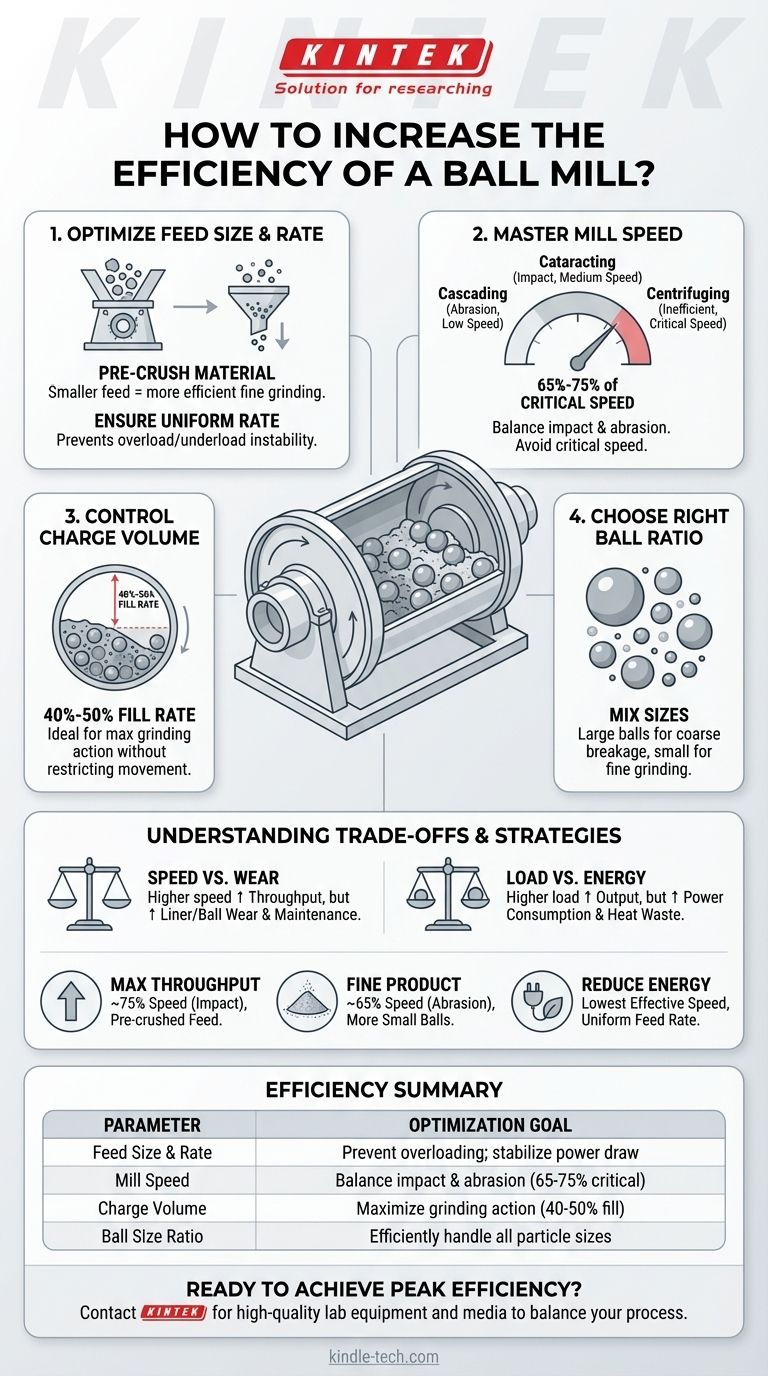

Increasing the efficiency of a ball mill is achieved by systematically optimizing five critical parameters: the size and rate of the material you feed in, the speed at which the mill rotates, the volume of material inside, and the size distribution of the steel balls that perform the grinding. Each factor is interconnected, and mastering their balance is the key to maximizing output while minimizing wasted energy.

True ball mill efficiency is not about maximizing speed or load. It's about creating a balanced grinding environment where the energy you input is maximally transferred to the material through the correct combination of impact and abrasion.

The Foundation: Optimizing Your Input Material

Before the mill even starts turning, the greatest gains in efficiency can be made by controlling what you put into it. The ball mill should be viewed as a finishing tool, not a primary crusher.

Control the Feed Size

The energy required to break a particle is proportional to its size. Feeding oversized material forces the mill to do the heavy work of primary crushing, which it does inefficiently.

By pre-crushing material to a smaller, more appropriate size, you allow the ball mill to focus its energy on the fine grinding it was designed for.

Ensure a Uniform Feed Rate

An inconsistent feed rate causes instability. A sudden surge in material can overload the mill, causing it to choke and grind poorly.

Conversely, an insufficient feed rate causes the mill to run under-loaded. This leads to inefficient grinding where the steel balls grind against each other and the liners, wasting energy and causing excessive wear.

Mastering the Grinding Environment

Inside the cylinder is where the core process of comminution (particle size reduction) occurs. Controlling this dynamic environment is essential for efficiency.

The Critical Role of Mill Speed

The speed of rotation dictates the motion of the grinding media. This motion falls into two main categories.

- Cascading: At lower speeds, the balls tumble down the face of the charge, creating friction and abrasion. This is ideal for fine grinding.

- Cataracting: At higher speeds, the balls are thrown into the air and crash down onto the material. This creates high-impact forces, which are effective for breaking down coarser particles.

Operating too close to the "critical speed"—the speed at which balls centrifuge and cling to the liner—results in almost no grinding at all. The optimal speed is typically between 65% and 75% of this critical speed, depending on the desired grinding action.

The Importance of Charge Fill Rate

The fill rate, or charge volume, refers to how much of the cylinder is filled with both grinding media and material. This directly impacts power draw and grinding effectiveness.

An underfilled mill doesn't have enough grinding media to effectively break down the material. An overfilled mill restricts the movement of the balls, muffling their impact and reducing efficiency. Most ball mills operate most efficiently with a charge volume between 40% and 50%.

Choose the Right Steel Ball Ratio

The grinding media are not one-size-fits-all. A proper charge requires a mix of ball sizes to handle the range of particle sizes in the feed.

Large balls are necessary to break the largest feed particles, while smaller balls are more effective at the fine grinding required to produce the final product. The ideal ratio depends entirely on your feed size and target output size.

Understanding the Trade-offs

Optimizing a ball mill is not about maximizing any single variable, but about finding the most effective balance for your specific goal. Pushing one parameter too far often has negative consequences.

Speed vs. Wear

Increasing mill speed can increase throughput, but only to a point. Higher speeds dramatically accelerate the wear on the steel balls and the mill liners, leading to higher maintenance costs and more frequent downtime.

Load vs. Energy

A higher charge volume can process more material per hour, but it also significantly increases the mill's power consumption. Overloading the mill restricts grinding action, causing energy to be wasted as heat and noise instead of being used for size reduction.

Liner Design and Material

While not an operational variable, the liner is a critical component. The profile of the liner—specifically its "lifters"—is responsible for lifting the charge. A worn-out liner cannot lift the balls properly, which severely reduces grinding efficiency regardless of other settings.

How to Apply This to Your Operation

There is no single "best" setting for a ball mill. Efficiency is defined by your primary objective.

- If your primary focus is maximizing throughput: Operate closer to 75% of critical speed to favor impact grinding, and ensure your feed is properly pre-crushed to a consistent size.

- If your primary focus is achieving a very fine product: Use a lower speed (around 65% of critical) to promote cascading and abrasion, and ensure your grinding media includes a sufficient charge of smaller balls.

- If your primary focus is reducing energy costs: Maintain a perfectly uniform feed rate to avoid inefficient peaks and valleys in power draw, and operate at the lowest speed that still achieves your desired particle size.

Ultimately, improving ball mill efficiency is a process of continuous, data-driven adjustment to achieve a stable and balanced system.

Summary Table:

| Parameter | Key for Efficiency | Optimization Goal |

|---|---|---|

| Feed Size & Rate | Pre-crush material; maintain uniform rate | Prevent overloading/underloading; stabilize power draw |

| Mill Speed | Operate at 65%-75% of critical speed | Balance impact (cataracting) and abrasion (cascading) |

| Charge Volume | Maintain 40%-50% fill rate | Maximize grinding action without restricting ball movement |

| Ball Size Ratio | Mix large (coarse breakage) and small (fine grinding) balls | Efficiently handle the full range of particle sizes |

Ready to Achieve Peak Ball Mill Efficiency in Your Lab?

At KINTEK, we specialize in providing the high-quality lab equipment and consumables—including milling media and more—that are essential for optimizing your grinding processes. Our experts can help you select the right tools to balance speed, load, and media for your specific goals of throughput, product fineness, or energy savings.

Contact KINTEK today to discuss how our solutions can enhance your laboratory's productivity and reduce operational costs.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

- Small Injection Molding Machine for Lab Use

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- Why is a high-energy planetary ball mill preferred over traditional casting for nanocrystalline HEAs?

- How does a planetary high-energy ball mill contribute to the top-down preparation of layered materials? Optimize Yield

- How does a planetary ball mill enhance the electrocatalytic activity of La0.6Sr0.4CoO3-δ? Boost Your Catalyst Performance

- What is the specific role of a high-energy planetary ball mill in the synthesis of Ag-doped sulfide solid-state electrolytes?

- What is the role of a planetary ball mill in the preparation of NiCr-Al2O3-SrCO3 composite powders? Enhanced Homogeneity