Yes, a ball mill is a quintessential tool for fine grinding. It is specifically designed to reduce solid materials into a fine powder or slurry. By controlling its operational parameters, a ball mill can consistently produce particle sizes ranging from a few millimeters down to 10 microns, with specialized versions capable of achieving sub-micron and even nanometer-level fineness.

A ball mill is not just used for fine grinding; it is a foundational technology for achieving it. Its effectiveness lies in the dual forces of impact and attrition, but its true power is unlocked by precisely matching the mill's speed, media, and charge to the specific material and the target particle size.

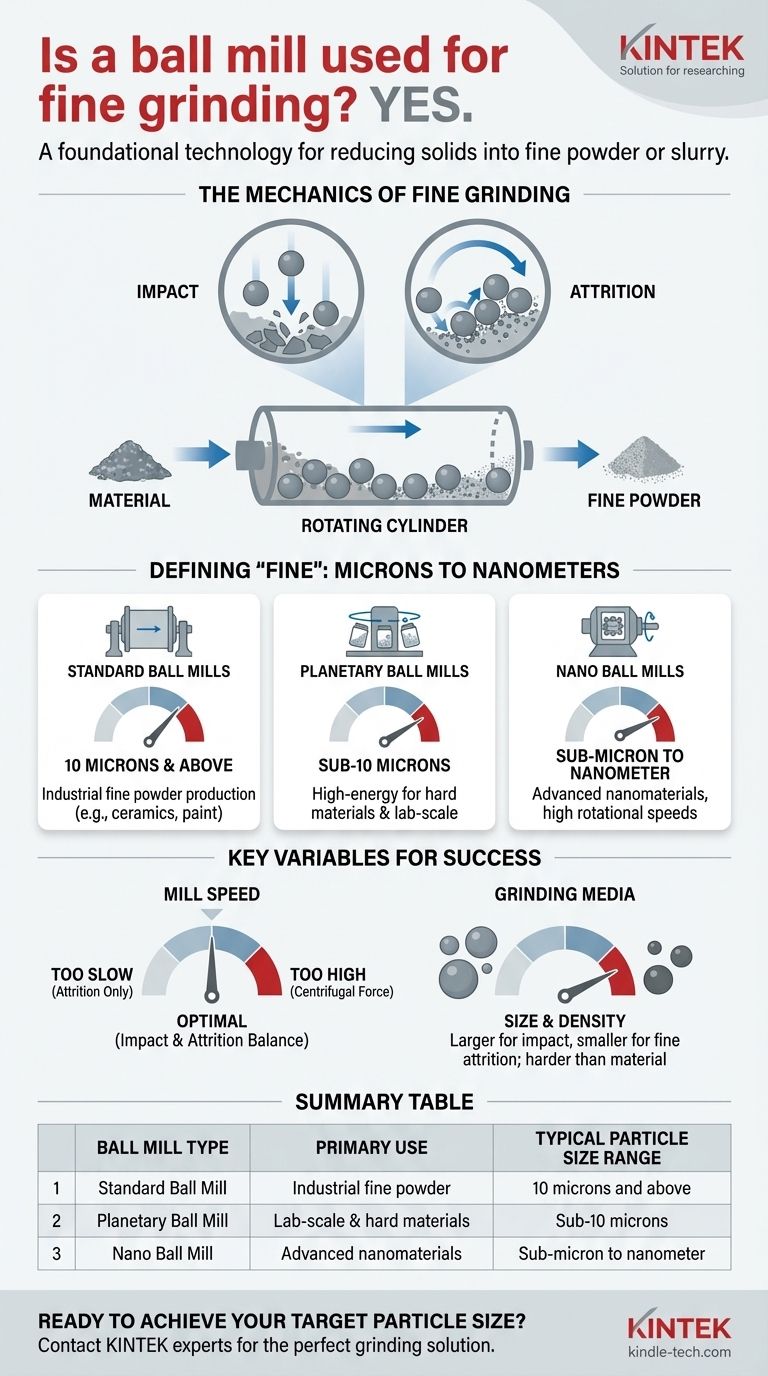

The Mechanics of Fine Grinding

A ball mill is a simple concept with sophisticated results. It consists of a rotating hollow cylinder partially filled with grinding media, typically steel or ceramic balls. As the cylinder turns, the media is lifted and then tumbles back down, grinding the material loaded inside.

The Principle of Impact and Attrition

The grinding action is achieved through two primary mechanisms.

Impact occurs when the grinding balls are lifted high up the side of the rotating cylinder and then drop, striking the material below. This powerful blow is highly effective at breaking down larger, brittle particles.

Attrition happens as the balls cascade and tumble over one another. This creates a constant shearing and rubbing action that grinds particles down, making it especially effective for producing very fine powders.

How a Ball Mill Works

In a typical setup, the material to be ground is fed into one end of the horizontal cylinder. As the mill rotates, the tumbling action of the balls progressively reduces the particle size. The finely ground material then exits through the discharge end, allowing for continuous operation.

Defining "Fine": From Microns to Nanometers

The term "fine grinding" can mean different things depending on the application. Ball mills are versatile enough to cover a wide spectrum of particle size requirements, from standard industrial powders to advanced nanomaterials.

Standard Ball Mills for Fine Powders

A conventional ball mill is highly effective for producing powders with a particle size at or below 10 microns. This makes it a workhorse in industries like mineral processing, ceramics, and paint manufacturing, where a consistent, fine powder is essential.

High-Energy and Planetary Mills

For more demanding applications, planetary ball mills offer higher energy input. In these devices, the grinding jars rotate on a large "sun" wheel while also spinning on their own axis. This combination of forces dramatically increases the grinding energy, making them ideal for very hard materials or for achieving smaller particle sizes more quickly.

Pushing to the Nanoscale

Specialized nano ball mills are engineered for ultimate fineness. By using very high rotational speeds and smaller grinding media, these mills can overcome the physical forces that hold materials together at a molecular level. This intensive process can reduce materials down to the sub-micron and nanometer scale, a critical requirement in pharmaceuticals, electronics, and advanced materials science.

Understanding the Key Variables and Trade-offs

Achieving the desired particle size is not automatic; it requires careful control over several key factors. Mismanaging these variables can lead to inefficient grinding or failure to reach the target fineness.

The Critical Factor of Mill Speed

The rotational speed of the mill is paramount. If the speed is too low, the balls will only slide and roll, relying solely on attrition, which is slow. If the speed is too high, centrifugal force will pin the balls and material to the cylinder wall, stopping the grinding action entirely. The optimal speed allows the balls to cascade, ensuring a perfect balance of impact and attrition.

Matching Media to Material

The grinding media—the balls themselves—must be chosen carefully. The size, density, and material of the balls dictate the grinding efficiency. Larger, denser balls create higher impact forces for breaking coarse feed, while smaller balls provide a greater surface area for fine attrition grinding. The media must also be harder than the material being ground to avoid contamination.

It's Not a One-Size-Fits-All Solution

While incredibly versatile, a ball mill is optimized for fine and ultra-fine grinding. For initial coarse crushing of very large rocks, other machines like jaw crushers are more energy-efficient. A ball mill performs best when fed a pre-crushed material, which it then refines to the final target size.

Making the Right Choice for Your Goal

Selecting the right grinding approach depends entirely on your end goal. The versatility of ball mills means there is likely a configuration suited to your needs.

- If your primary focus is reliable production of industrial powders (e.g., 10-50 microns): A standard, continuous-feed ball mill is a proven and cost-effective solution.

- If your primary focus is laboratory-scale grinding or processing very hard materials: A high-energy planetary ball mill provides the necessary force and flexibility.

- If your primary focus is producing advanced materials with sub-micron or nanometer particle sizes: You must invest in a specialized nano ball mill designed for high-intensity grinding.

By understanding these core principles, you can precisely control the milling process to achieve your desired particle size with remarkable consistency.

Summary Table:

| Ball Mill Type | Primary Use | Typical Particle Size Range |

|---|---|---|

| Standard Ball Mill | Industrial fine powder production | 10 microns and above |

| Planetary Ball Mill | Lab-scale & hard materials | Sub-10 microns |

| Nano Ball Mill | Advanced nanomaterials | Sub-micron to nanometer |

Ready to Achieve Your Target Particle Size?

Whether you need reliable fine powder production or are pushing the boundaries of nanotechnology, the right grinding equipment is critical. KINTEK specializes in providing high-quality ball mills and expert consultation to help you select the perfect solution for your material and fineness requirements.

Contact our lab equipment experts today to discuss how we can optimize your grinding process for superior results and efficiency.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- What is the critical role of the planetary ball mill in the pretreatment of alloy powders like Cr40-Si60?

- What is the primary function of a planetary ball mill in Al/B4C composite slurry prep? Achieve Uniform Dispersion

- What is the specific role of a planetary ball mill in the preparation of Ag-SnO2-Y2O3 composite powders?

- What role does a planetary ball mill play in eggshell fertilizer production? Unlock Superior Chemical Reactivity

- What role does a planetary ball mill play in the solid-state synthesis of perovskite oxides? Master Material Activation

- What is the function of a ball mill in LATP preparation? Optimize Your Solid Electrolyte for High Conductivity

- What is the primary function of a planetary ball mill? Mastering SiC/Al Composite Mixing for Homogeneity

- What is the function of a planetary ball mill for all-solid-state batteries? Engineer Superior Solid-Solid Interfaces