Yes, biofuels are classified as a renewable energy source. They are derived from biomass—organic matter like plants, algae, or animal waste—which can be replenished in a relatively short period. Unlike finite fossil fuels, the raw materials for biofuels can be grown and harvested, making them part of a continuous cycle.

The core distinction is that biofuels originate from recently living organic matter that can be regrown, placing them in the renewable category. However, their true sustainability and environmental benefit depend entirely on how the source biomass is cultivated, harvested, and processed.

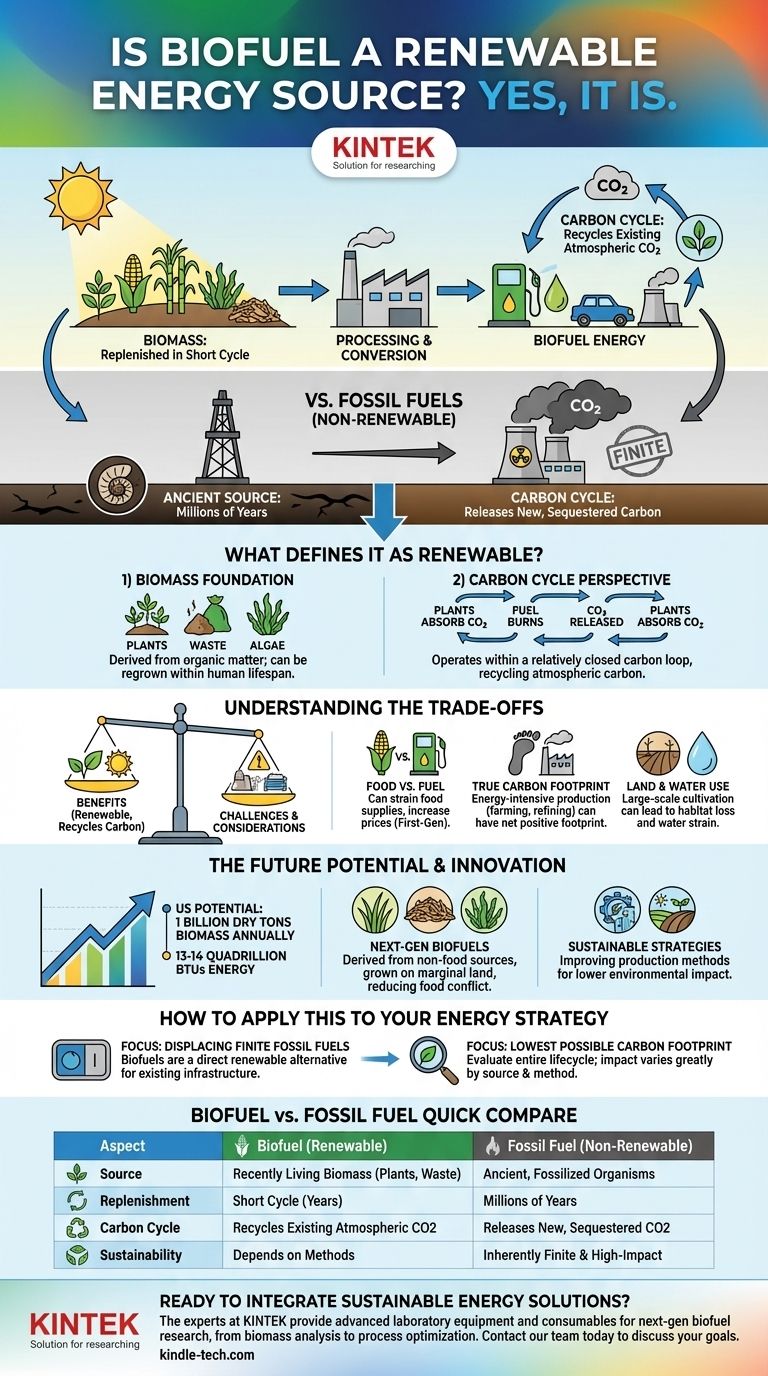

What Defines Biofuel as Renewable?

The renewable status of biofuel is tied to its origin and its role in the carbon cycle. It stands in direct contrast to the finite nature of fossil fuels.

The Foundation: Biomass

Biofuels are generated from biomass. This is a broad term for any organic material, including agricultural crops like corn and sugarcane, wood, algae, and even organic waste streams.

Because these sources can be replenished through natural processes or farming within a human lifespan, the energy they contain is considered renewable.

The Carbon Cycle Perspective

In theory, biofuels operate within a relatively closed carbon loop. The plants used for biofuel absorb carbon dioxide (CO2) from the atmosphere as they grow.

When the biofuel is burned, it releases that same CO2 back into the atmosphere. This is fundamentally different from burning fossil fuels.

Contrast with Fossil Fuels

Fossil fuels like coal, oil, and natural gas are the remains of ancient organisms that have been buried for millions of years.

Burning them releases vast quantities of carbon that have been locked out of the active atmosphere for eons. This adds new carbon to the system, driving climate change. Biofuels, in contrast, recycle existing atmospheric carbon.

Understanding the Trade-offs

While renewable, biofuels are not a perfect solution. Their production and use come with significant environmental and economic considerations that must be carefully managed.

The "Food vs. Fuel" Dilemma

First-generation biofuels are often made from food crops like corn (for ethanol) and soybeans (for biodiesel). Diverting large amounts of these crops to fuel production can strain food supplies and potentially increase prices.

The True Carbon Footprint

The idea of a perfectly closed carbon loop is an oversimplification. The entire process of producing biofuel—from farming to refining—requires energy.

This includes running farm machinery, producing fertilizers, and powering the conversion process, all of which often rely on fossil fuels. This means most biofuels have a net positive carbon footprint, though it's typically lower than that of gasoline or diesel.

Land and Water Use

Cultivating crops for biofuel at a large scale requires significant land and water resources. If not managed sustainably, this can lead to deforestation, habitat loss, and strain on local water supplies, offsetting some of the environmental benefits.

The Future Potential of Biofuels

Despite these challenges, biofuels have the potential to be a major contributor to our energy portfolio. The key lies in improving production methods and shifting to more sustainable sources.

A Growing Energy Source

Research indicates that with advancements in agricultural practices and plant breeding, the United States alone could produce up to 1 billion dry tons of biomass annually.

This quantity of biomass could generate around 13–14 quadrillion BTUs of energy per year, a significant portion of a nation's energy needs.

Next-Generation Biofuels

Innovation is focused on second and third-generation biofuels. These are derived from non-food sources like switchgrass, wood chips, and agricultural waste, or are cultivated from algae.

These advanced biofuels significantly reduce the "food vs. fuel" conflict and can often be grown on marginal land, minimizing the impact on primary ecosystems.

How to Apply This to Your Energy Strategy

Understanding whether biofuel is the right choice depends on your specific goals.

- If your primary focus is displacing finite fossil fuels: Biofuels are a direct, renewable alternative that can often be used with existing infrastructure.

- If your primary focus is achieving the lowest possible carbon footprint: You must evaluate the entire lifecycle of a specific biofuel, as its true environmental impact varies greatly depending on its source and production method.

Ultimately, biofuel is a complex but vital component of the broader transition to a sustainable energy future.

Summary Table:

| Aspect | Biofuel (Renewable) | Fossil Fuel (Non-Renewable) |

|---|---|---|

| Source | Recently living biomass (plants, waste) | Ancient, fossilized organisms |

| Replenishment | Short cycle (years) | Millions of years |

| Carbon Cycle | Recycles existing atmospheric CO2 | Releases new, sequestered CO2 |

| Sustainability | Depends on farming & processing methods | Inherently finite & high-impact |

Ready to integrate sustainable energy solutions into your operations? The experts at KINTEK are here to help. We provide the advanced laboratory equipment and consumables necessary for researching and developing next-generation biofuels, from biomass analysis to process optimization. Contact our team today to discuss how we can support your renewable energy goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Evaporation Boat for Organic Matter

People Also Ask

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds