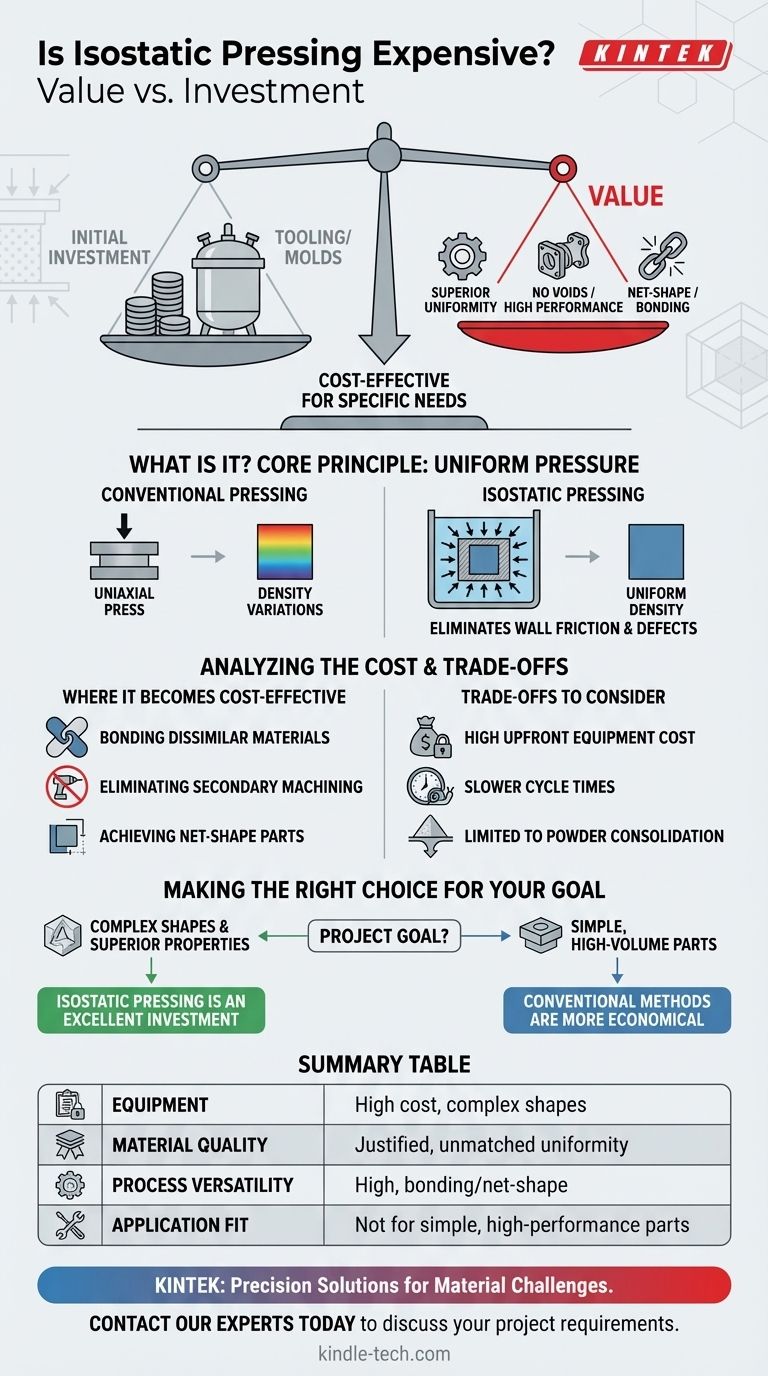

To be direct, the cost of isostatic pressing is a matter of perspective. While the initial investment in equipment can be substantial, the process is often highly cost-effective—and sometimes the only viable option—for manufacturing parts where uniform density, complex geometry, and superior material properties are critical.

The core takeaway is this: Isostatic pressing is not a low-cost commodity process. Its value and cost-effectiveness are realized when its unique ability to produce highly uniform, high-performance components solves problems that less-advanced manufacturing methods cannot.

What is Isostatic Pressing and Why Is It Used?

To understand the cost, you must first understand the value. Isostatic pressing is a powder processing technique that compacts materials by subjecting them to uniform pressure from all directions.

The Core Principle: Uniform Pressure

Unlike conventional pressing that applies force along a single axis (uniaxially), isostatic pressing immerses a powdered material sealed in a flexible mold into a fluid. This fluid is then pressurized, exerting an equal, simultaneous force over the entire surface of the part.

This method completely eliminates the wall friction found in die pressing, which is a common source of defects and density variations.

The Primary Benefit: Unmatched Material Uniformity

The application of uniform pressure results in a finished product with a remarkably consistent grain structure and density. This process eliminates voids and internal air pockets, leading to parts with significantly increased strength, reliability, and dimensional accuracy.

It unlocks the ability to create complex shapes that would be impossible to press uniformly with traditional methods.

Key Techniques: Wet-Bag vs. Dry-Bag

There are two main approaches to the process:

- Wet-Bag Isostatic Pressing: The flexible mold containing the powder is fully submerged in a pressure vessel filled with the pressurizing fluid. This method is highly versatile for various shapes and R&D.

- Dry-Bag Isostatic Pressing: The flexible mold is integrated directly into the pressure vessel. Powder is loaded, pressed, and ejected without removing the mold, which is better suited for higher-volume production.

Analyzing the True Cost of Isostatic Pressing

The "expense" of the process is a balance between its upfront costs and the savings or value it generates compared to alternatives.

Initial Capital Investment

The most significant cost factor is the pressure vessel and its associated high-pressure generation system. This equipment is specialized and represents a substantial capital investment, particularly for large parts or very high pressures.

Tooling and Molds

The flexible molds, often made of polyurethane or other elastomers, are another cost center. While less expensive than the hardened steel dies used in uniaxial pressing, their lifespan is shorter, making them a recurring operational expense.

Where It Becomes Cost-Effective

The process proves its financial worth in specific scenarios. For example, when bonding dissimilar materials, isostatic pressing can replace extremely costly and complex diffusion bonding processes, saving significant money.

It also becomes cost-effective when it eliminates the need for extensive and expensive secondary machining operations that would otherwise be required to correct for the non-uniformities of other methods.

Understanding the Trade-offs

No manufacturing process is without its limitations. Objectivity requires acknowledging where isostatic pressing may not be the best fit.

High Upfront Equipment Cost

The primary barrier to entry is the initial capital expenditure. For companies not requiring its specific benefits, this cost can be prohibitive.

Slower Cycle Times

Compared to high-speed automated processes like uniaxial pressing, isostatic pressing is generally slower. This can make it less economical for very simple, high-volume parts where maximum throughput is the main driver.

Limited to Powder Consolidation

The process is fundamentally designed for consolidating powders. It is not a universal solution for all manufacturing challenges and must be applied where its unique capabilities with powdered materials are needed.

Making the Right Choice for Your Goal

Whether isostatic pressing is "expensive" depends entirely on your project's definition of value.

- If your primary focus is creating complex shapes with superior and uniform material properties: Isostatic pressing is an excellent investment, as it can produce net-shape or near-net-shape parts that other methods simply cannot.

- If your primary focus is bonding difficult materials or composites: The process is often a highly cost-effective alternative to more complex, multi-step fabrication and bonding techniques.

- If your primary focus is mass-producing simple, low-cost parts: A more conventional method like uniaxial die pressing will almost certainly be a more economical choice.

Ultimately, isostatic pressing is a precision tool for solving complex material and geometric challenges, and its cost is justified by the exceptional quality of its results.

Summary Table:

| Aspect | Cost Factor | Benefit |

|---|---|---|

| Equipment | High initial investment | Enables production of complex shapes impossible with other methods |

| Material Quality | Justified by superior results | Unmatched density uniformity, eliminating voids and increasing strength |

| Process Versatility | Higher than uniaxial pressing | Ideal for bonding dissimilar materials and creating net-shape parts |

| Application Fit | Not for high-volume, simple parts | Highly cost-effective for high-performance components where quality is critical |

Ready to achieve superior material performance with precision isostatic pressing?

KINTEK specializes in advanced lab equipment and consumables, providing solutions for laboratories that demand the highest quality in material processing. Our expertise can help you determine if isostatic pressing is the right, cost-effective solution for your specific application, ensuring you get the uniform density and complex geometries you need.

Contact our experts today to discuss your project requirements and discover the value we can bring to your lab.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance

- What are the components of a hot isostatic pressing system? A Guide to Core HIP Equipment

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- What is the HIP material process? Achieve Near-Perfect Density and Reliability