Yes, for the vast majority of applications, PVD coating is considered food-safe. This advanced finishing process creates a surface that is chemically and biologically inert, meaning it does not react with or leach into food. Because the coating forms an extremely strong molecular bond with the underlying material, it is highly resistant to flaking, wear, and corrosion.

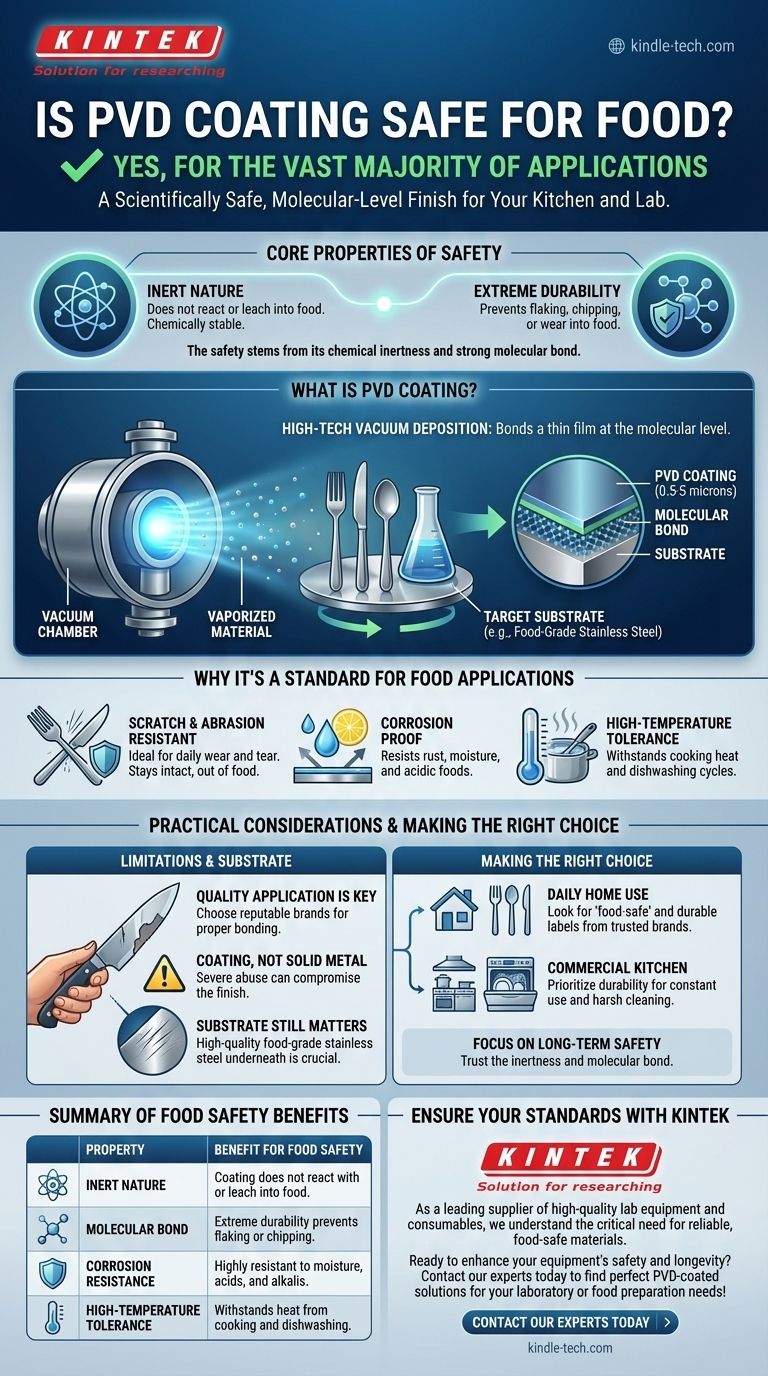

The safety of PVD coatings for food contact stems from two core properties: the inert nature of the materials used and the extreme durability of the finish, which prevents the coating from chipping or degrading into your food.

What Exactly is PVD Coating?

Physical Vapor Deposition (PVD) is not a paint or a simple plating process. It is a high-tech vacuum deposition method that bonds a very thin film of material to a surface on a molecular level.

A Molecular-Level Finish

The process involves vaporizing a solid material in a vacuum and depositing it onto the target object, often stainless steel. This creates an incredibly thin—typically 0.5 to 5 microns—but exceptionally hard and durable surface layer.

Inert and Biocompatible

Most materials used for PVD coatings intended for food contact are chosen for their biocompatibility. They are chemically inert, meaning they won't corrode, oxidize, or react when they come into contact with acids or alkalis in food.

The Importance of the Substrate

The final properties of a PVD-coated item depend heavily on the substrate, or the material underneath. The coating enhances the properties of the base metal, but the core material (like food-grade stainless steel) provides the foundational structure.

Why PVD is a Standard in Food Applications

The physical properties that make PVD coatings so resilient are the same ones that ensure their safety. A finish that cannot be easily damaged is one that will not contaminate its surroundings.

Extreme Durability and Resistance

PVD coatings are renowned for their hardness and resistance to abrasion and scratches. This is critical for items like cutlery and commercial kitchen equipment that face significant daily wear and tear. A coating that doesn't scratch off stays out of your food.

Superior Corrosion Proofing

The coating creates a seamless barrier that is highly resistant to corrosion and oxidation. This prevents rust or other chemical reactions that can occur when metal is exposed to moisture, detergents, and acidic foods.

High-Temperature Tolerance

The finish can withstand high temperatures without degrading, making it suitable for various kitchen tools and equipment that may be exposed to heat during cooking or commercial dishwashing cycles.

Understanding the Practical Limitations

While PVD is an excellent and safe technology, its effectiveness is rooted in the quality of its application and the context of its use.

Safety Depends on Quality Application

The exceptional bond strength of a PVD coating is central to its safety. A finish from a reputable manufacturer will adhere properly, but a poorly applied coating could theoretically fail. Always choose products from trusted brands that specify food-safe usage.

It's a Coating, Not Solid Metal

Remember that PVD is an extremely durable surface layer, not the core material. While it can withstand immense wear, severe abuse with highly abrasive tools or cleaners could eventually compromise the finish.

The Substrate Still Matters

In the unlikely event that the coating is breached, the safety of the item then depends on the underlying material. This is why high-quality, food-grade stainless steel is the preferred substrate for kitchen applications.

Making the Right Choice for Your Needs

Selecting and maintaining PVD-coated items is straightforward when you understand what to look for.

- If your primary focus is daily home use: Look for reputable brands for cutlery or fixtures that explicitly market their PVD products as food-safe and durable for everyday life.

- If your primary focus is a commercial kitchen: Prioritize PVD for its ability to withstand constant use, harsh cleaning cycles, and high temperatures, which extends the life of your equipment.

- If your primary focus is long-term safety: Trust that PVD's inertness and molecular bond are its key safety features, preventing any material from ever migrating into your food.

By choosing quality PVD-coated products, you are selecting a finish engineered for both exceptional performance and food-grade safety.

Summary Table:

| Property | Benefit for Food Safety |

|---|---|

| Inert Nature | Coating does not react with or leach into food, ensuring no contamination. |

| Molecular Bond | Extreme durability prevents flaking, chipping, or wear into food. |

| Corrosion Resistance | Highly resistant to moisture, acids, and alkalis, preventing rust and degradation. |

| High-Temperature Tolerance | Withstands heat from cooking and commercial dishwashing without degrading. |

Ensure your lab or kitchen equipment meets the highest safety standards with KINTEK.

As a leading supplier of high-quality lab equipment and consumables, we understand the critical need for reliable, food-safe materials. Our expertise in durable, chemically inert coatings ensures your tools perform safely and effectively, day after day.

Ready to enhance your equipment's safety and longevity? Contact our experts today to find the perfect PVD-coated solutions for your laboratory or food preparation needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process