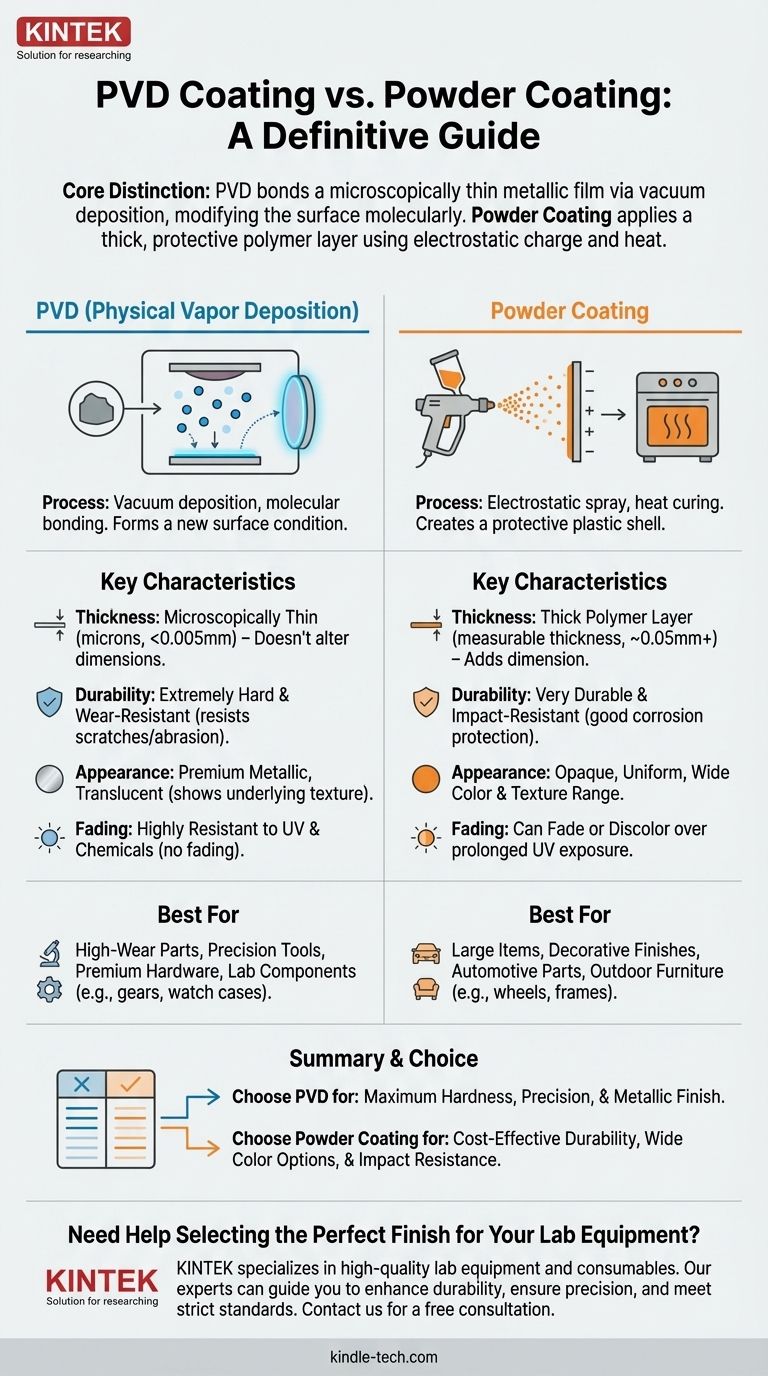

No, PVD is not the same as powder coating. They are fundamentally different finishing processes in terms of application, material, and final properties. PVD (Physical Vapor Deposition) uses a vacuum to bond a microscopically thin metallic film to a surface, while powder coating applies a thick, paint-like polymer layer using an electrostatic charge and heat.

The core distinction is simple: PVD modifies the object's original surface on a molecular level to create a new, harder surface. Powder coating, in contrast, covers the object with a thick, protective plastic shell.

What is Powder Coating?

Powder coating is essentially a high-durability paint applied as a dry powder. It's a common and cost-effective method for adding a protective and decorative finish to a wide range of metal products.

The Application Process

The process involves spraying a finely ground powder of pigment and resin onto an electrostatically charged part. This charge makes the powder adhere to the surface. The part is then cured in an oven, which melts the powder into a smooth, continuous film that hardens as it cools.

The Resulting Finish

The result is a thick, hard, and opaque finish that is much more durable than conventional liquid paint. It creates a distinct layer over the object's surface, which can also help hide minor surface imperfections.

What is Physical Vapor Deposition (PVD)?

PVD is a high-tech vacuum deposition process that produces a very thin, yet extremely hard and durable, coating. It is often used for high-performance applications where wear resistance is critical.

The Application Process

Inside a vacuum chamber, a solid material (like titanium or chromium) is vaporized into a plasma of atoms or molecules. These vaporized particles are then deposited onto the target object, where they bond to the surface at a molecular level, forming a new, thin-film surface layer.

The Resulting Finish

PVD does not create a substantial coating; it forms a new surface condition. This bonded layer is often measured in microns (thousandths of a millimeter) and is so thin that it perfectly conforms to the original surface texture. The finish is typically a metallic or ceramic layer that is exceptionally durable.

Key Differences at a Glance

Understanding how these two processes differ in their core attributes is key to selecting the right one for your needs.

Material and Thickness

PVD coatings are metal or metal-ceramic films that are microscopically thin. This thinness means they do not significantly alter a part's dimensions.

Powder coatings are thick polymer (plastic) layers. This adds measurable thickness to the part, which must be accounted for in parts with tight tolerances.

Durability and Hardness

PVD is generally considered more durable and significantly harder than powder coating. It excels in resisting scratches, wear, and abrasion.

Powder coating is very durable and provides excellent impact and corrosion resistance, but it is not as hard or wear-resistant as PVD.

Appearance and Texture

PVD produces a premium metallic finish and is often translucent, allowing the underlying surface texture (like brushed or polished metal) to show through.

Powder coating is opaque and provides a more uniform, paint-like appearance. It is available in a vast range of colors, gloss levels, and textures.

Fading and Discoloration

PVD is extremely resistant to UV light and chemical exposure, making it far less prone to fading or discoloration over time.

Powder coatings, while durable, can fade or change color after prolonged exposure to the elements, similar to high-quality paints.

Understanding the Trade-offs

Neither process is universally superior; the right choice depends entirely on the application and your specific goals.

Cost and Complexity

The PVD process requires specialized vacuum equipment and is significantly more complex and expensive than powder coating. This makes it more suitable for high-value or high-performance components.

Substrate Compatibility

PVD is typically applied to metals and materials that can withstand the high temperatures and vacuum environment. Powder coating is also applied mainly to metals but is generally more forgiving in its application requirements.

Aesthetic Goals

If you need a wide variety of opaque colors or special effects like textures and wrinkles, powder coating is the far more versatile option. If you require a specific, durable metallic sheen (like gold, black, or rose gold) that won't chip or fade, PVD is the premier choice.

Making the Right Choice for Your Application

Your final decision should be driven by the primary requirement of your product.

- If your primary focus is maximum hardness and wear resistance: PVD is the superior choice for high-contact items like tools, watch casings, industrial parts, or premium hardware.

- If your primary focus is a wide range of color options and cost-effective durability: Powder coating is the ideal solution for larger items like automotive wheels, bicycle frames, or outdoor furniture.

- If your primary focus is preserving fine surface detail with a premium metallic finish: PVD's thin-film nature makes it the only viable option.

By understanding these core differences, you can choose a finish that truly matches your product's performance and aesthetic requirements.

Summary Table:

| Feature | PVD Coating | Powder Coating |

|---|---|---|

| Process | Vacuum deposition, molecular bonding | Electrostatic spray, heat curing |

| Thickness | Microscopically thin (microns) | Thick polymer layer |

| Durability | Extremely hard, wear-resistant | Durable, impact-resistant |

| Appearance | Premium metallic, translucent | Opaque, wide color range |

| Cost | Higher, specialized equipment | Lower, cost-effective |

| Ideal For | High-wear parts, premium hardware | Large items, decorative finishes |

Need Help Selecting the Perfect Finish for Your Lab Equipment?

Choosing between PVD and powder coating is critical for the longevity and performance of your laboratory instruments and components. KINTEK specializes in providing high-quality lab equipment and consumables, and we understand the importance of a durable, precise finish.

Let our experts guide you to the optimal solution for your specific needs. We can help you:

- Enhance durability for high-wear components like reactor parts or tooling.

- Select the right finish to meet strict laboratory cleanliness and corrosion resistance standards.

- Ensure precision with coatings that maintain critical part dimensions.

Contact us today to discuss your project requirements and discover how KINTEK's expertise can add value to your laboratory operations.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose