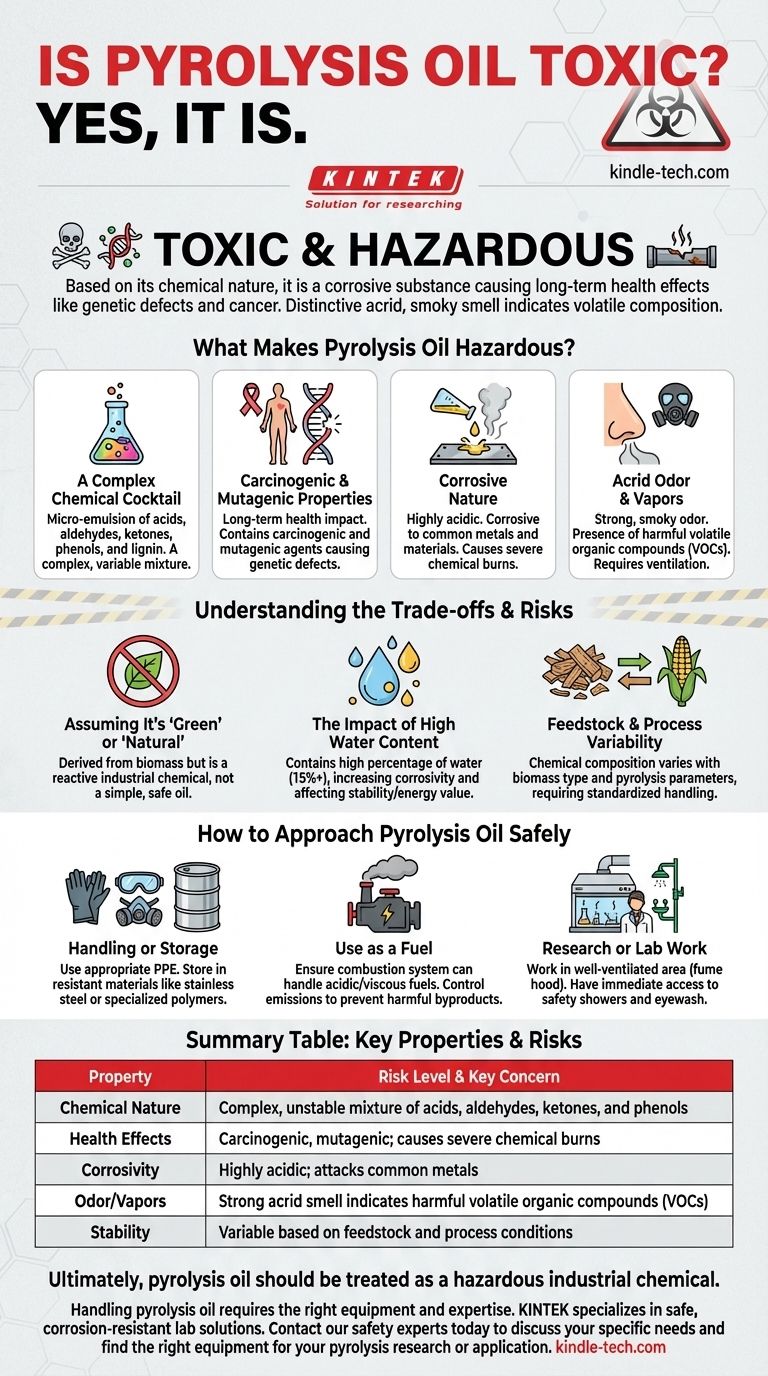

Yes, pyrolysis oil is toxic and hazardous. Based on its chemical nature, it is classified as a corrosive substance that can cause serious long-term health effects, including genetic defects and cancer. The oil's distinctive acrid, smoky smell is an immediate indicator of its volatile and reactive chemical composition.

The core issue with pyrolysis oil is that it's not a simple, refined product. It is a complex, unstable mixture of hundreds of organic compounds formed by the rapid, incomplete decomposition of biomass, resulting in a substance that is both corrosive and contains known carcinogenic and mutagenic agents.

What Makes Pyrolysis Oil Hazardous?

The toxicity of pyrolysis oil stems directly from how it is made. The process of fast pyrolysis rapidly heats organic materials like wood or agricultural waste in an oxygen-starved environment, essentially freezing the chemical breakdown process halfway.

A Complex Chemical Cocktail

The resulting liquid is not a uniform oil but a micro-emulsion. It contains a vast array of compounds, including acids, aldehydes, ketones, and phenols, suspended with larger molecules from lignin, a structural component of plants. This complex and variable mixture is the root cause of its hazardous properties.

Carcinogenic and Mutagenic Properties

The most severe risk associated with pyrolysis oil is its long-term health impact. It is known to contain compounds that are carcinogenic (cancer-causing) and mutagenic (capable of causing genetic defects). This requires strict handling protocols to prevent exposure.

Corrosive Nature

Pyrolysis oil is highly acidic, making it corrosive to many common metals and materials. This poses a significant risk to storage containers and equipment, and it can cause severe chemical burns upon contact with skin.

Acrid Odor and Vapors

The strong, smoky odor is a clear warning sign. It indicates the presence of volatile organic compounds (VOCs) that can be harmful when inhaled. Proper ventilation is non-negotiable when working with this substance.

Understanding the Trade-offs and Risks

While pyrolysis oil offers potential as a renewable fuel source, its hazardous properties create significant challenges that must be managed. Misunderstanding these risks can lead to serious safety and environmental incidents.

Assuming It's a "Green" or "Natural" Oil

Because it is derived from biomass, some mistakenly assume pyrolysis oil is as safe as a vegetable or mineral oil. This is incorrect. It is a reactive industrial chemical and must be treated with the same respect as other hazardous materials.

The Impact of High Water Content

The oil typically contains a high percentage of water (often over 15%). This water is mixed with the organic acids, contributing to the oil's corrosivity and affecting its stability and energy value as a fuel.

Feedstock and Process Variability

The exact chemical composition—and therefore the specific toxicity profile—of pyrolysis oil can change depending on the type of biomass used (e.g., pine wood vs. corn stover) and the precise parameters of the pyrolysis process. This variability makes standardized handling procedures essential.

How to Approach Pyrolysis Oil Safely

Your strategy for managing pyrolysis oil must be dictated by its hazardous properties. The goal is to minimize exposure and mitigate its corrosive effects.

- If your primary focus is handling or storage: You must use appropriate Personal Protective Equipment (PPE), including chemical-resistant gloves, splash-proof goggles, and respiratory protection, and store it in containers made of resistant materials like stainless steel or specialized polymers.

- If your primary focus is its use as a fuel: Ensure the combustion system is designed to handle acidic and viscous fuels, and that emissions are properly controlled to prevent the release of harmful byproducts into the atmosphere.

- If your primary focus is research or lab work: Always work in a well-ventilated area, preferably within a fume hood, and have immediate access to safety showers and eyewash stations.

Ultimately, pyrolysis oil should always be treated as a hazardous industrial chemical, not as a simple biofuel.

Summary Table:

| Property | Risk Level & Key Concern |

|---|---|

| Chemical Nature | Complex, unstable mixture of acids, aldehydes, ketones, and phenols |

| Health Effects | Carcinogenic, mutagenic; causes severe chemical burns |

| Corrosivity | Highly acidic; attacks common metals |

| Odor/Vapors | Strong acrid smell indicates harmful volatile organic compounds (VOCs) |

| Stability | Variable based on feedstock (wood, agricultural waste) and process conditions |

Handling pyrolysis oil requires the right equipment and expertise. KINTEK specializes in providing safe, corrosion-resistant lab equipment and consumables for handling hazardous materials like pyrolysis oil. From storage containers to fume hoods, our solutions are designed to protect your personnel and ensure operational safety.

Ensure your lab is equipped to manage these risks effectively. Contact our safety experts today to discuss your specific needs and find the right equipment for your pyrolysis research or application.

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

People Also Ask

- What is an autoclave used for in a lab? Achieve Total Sterilization for Lab Safety and Integrity

- What instruments are sterilized in an autoclave the temperature must be maintained at what? The Essential Guide to Effective Sterilization

- Why is it important to use the autoclave to sterilize laboratory tools? Ensure Complete Sterility for Reliable Results

- What equipment is used for laboratory sterilization? A Guide to Autoclaves, Ovens & Filtration

- Why is autoclave done for 15 minutes? The Science Behind Sterilization Cycles