In any milling process, the final particle size distribution is primarily determined by the physical characteristics of the grinding media, the duration of the milling, and the operational speed of the mill. These core parameters dictate the frequency and energy of the impacts that break down the material, directly shaping its final fineness and consistency.

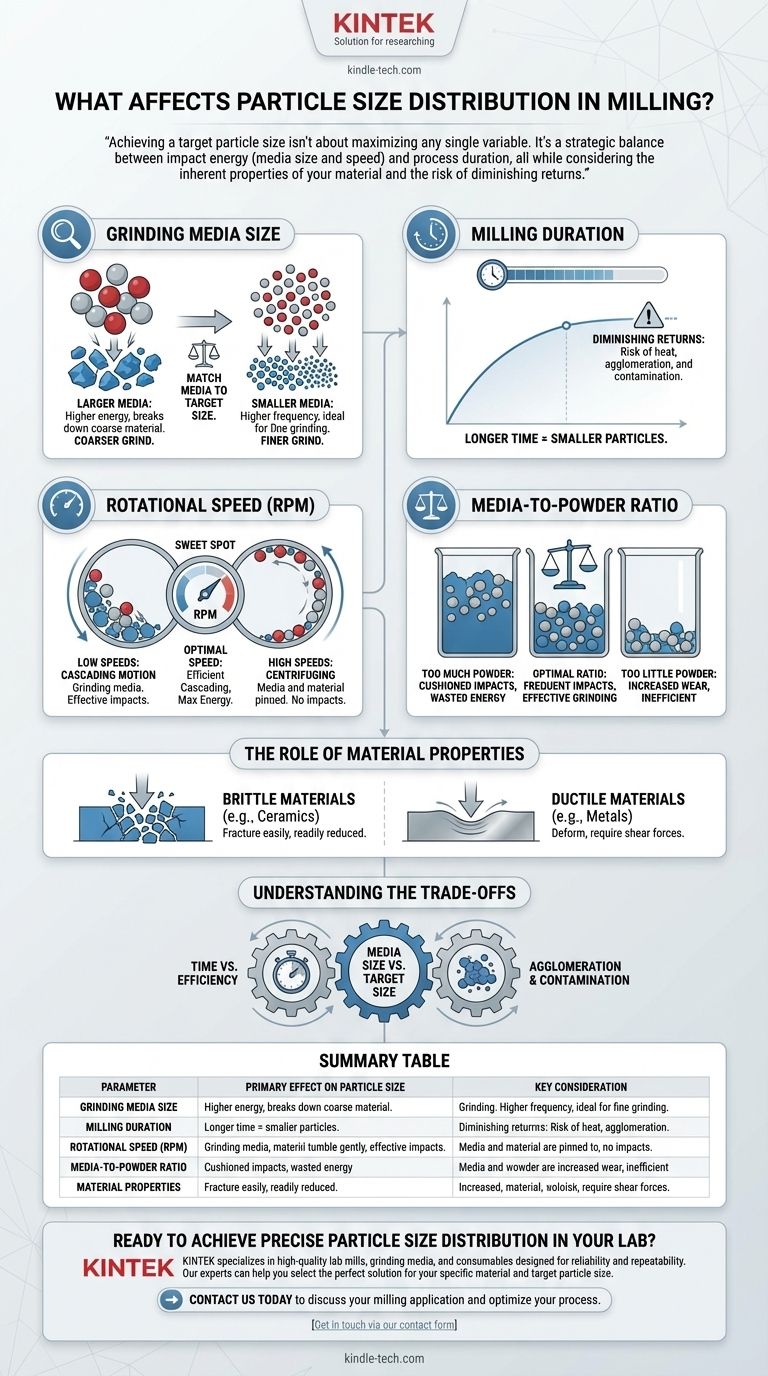

Achieving a target particle size isn't about maximizing any single variable. It's a strategic balance between impact energy (media size and speed) and process duration, all while considering the inherent properties of your material and the risk of diminishing returns.

The Core Parameters of Milling

To effectively control the outcome of a milling operation, you must understand how each key variable influences the process. These factors do not work in isolation; they interact to create a specific grinding environment.

Grinding Media Size

The size of the grinding media (e.g., the balls in a ball mill) is a primary lever for controlling impact dynamics.

There is a direct relationship between media size and impact energy. Larger media are heavier and deliver higher energy with each collision, making them effective for breaking down large, tough initial particles.

Conversely, smaller media create a much higher number of impact points. While each individual impact has less energy, the increased frequency is ideal for fine grinding and achieving a smaller final particle size.

Milling Duration

Milling time is the most straightforward variable but is often used inefficiently.

Generally, longer grinding times lead to smaller particles. The material is subjected to more impacts, leading to a progressive reduction in size.

However, the process is subject to diminishing returns. After a certain point, the energy input primarily generates heat, can cause particle agglomeration, or may lead to contamination from wear on the media and jar.

Rotational Speed (RPM)

The speed of the mill dictates the motion of the grinding media and the type of forces exerted.

At low speeds, media will simply tumble or cascade, which is an efficient motion for grinding. At high speeds, centrifugal force can pin the media and material against the wall of the milling jar, drastically reducing or even eliminating effective impacts.

There is an optimal speed for every mill and media combination that maximizes the energy of the cascading impacts without causing centrifuging.

Media-to-Powder Ratio

The ratio of the volume or weight of the grinding media to the material being processed is critical for efficiency.

An optimal ratio ensures that there is enough media to create frequent impacts but also enough free space for the powder to move and be effectively ground. Too much powder will cushion the impacts, while too little will result in wasted energy and increased wear.

The Role of Material Properties

The material itself is not a passive participant. Its inherent characteristics will profoundly affect how it responds to the milling process.

Hardness and Brittleness

Brittle materials, like ceramics, fracture easily upon impact and are readily reduced in size.

Ductile materials, like certain metals, may deform or flatten rather than shatter. This requires a different milling strategy, often involving shear forces in addition to direct impacts.

Understanding the Trade-offs

Effective milling requires balancing competing factors. Pushing one variable to its extreme often creates negative consequences.

Time vs. Efficiency

Milling for excessively long periods does not guarantee finer particles. It often leads to wasted energy, potential sample contamination from media erosion, and undesirable temperature increases that can alter the material's properties.

Media Size vs. Target Particle Size

Using large media to achieve very fine particles is highly inefficient. The high-energy impacts are not effective on tiny particles. You must match the media size to the target particle size—start with larger media for coarse material and switch to smaller media for fine grinding.

Agglomeration and Contamination

Overly aggressive or prolonged milling, especially in a dry environment, can increase the surface energy of particles, causing them to clump together (agglomerate). This negates the size reduction effort. Furthermore, long milling times increase the risk of introducing contaminants from the grinding media or jar into your sample.

How to Control Your Particle Size Distribution

Your milling strategy should be dictated by your end goal. Use these principles to guide your decisions.

- If your primary focus is breaking down large, coarse material: Use larger grinding media at an optimal cascading speed to maximize impact energy.

- If your primary focus is producing very fine or nano-sized particles: Use smaller grinding media for longer durations to maximize the number of impact events. Consider wet milling to prevent agglomeration and manage heat.

- If your primary focus is achieving a narrow particle size distribution: Begin with optimized parameters (media size, speed, and time) and consider using a classification system to separate particles after an initial milling stage.

By methodically adjusting these variables, you can transform milling from a brute-force process into a precise engineering tool.

Summary Table:

| Parameter | Primary Effect on Particle Size | Key Consideration |

|---|---|---|

| Grinding Media Size | Larger media = coarser grind; Smaller media = finer grind | Match media size to target particle size for efficiency |

| Milling Duration | Longer time = smaller particles | Diminishing returns; risk of heat and contamination |

| Rotational Speed (RPM) | Optimal speed = efficient impacts; Too high = centrifuging | Find the balance between cascading and centrifuging |

| Media-to-Powder Ratio | Optimal ratio = efficient grinding; Imbalance = cushioning or wear | Ensure enough space for powder movement |

| Material Properties | Brittle materials fracture easily; Ductile materials deform | Adjust strategy based on material hardness and brittleness |

Ready to achieve precise particle size distribution in your lab? The right equipment is key to mastering these parameters. KINTEK specializes in high-quality lab mills, grinding media, and consumables designed for reliability and repeatability. Our experts can help you select the perfect solution for your specific material and target particle size.

Contact us today to discuss your milling application and optimize your process. ➡️ Get in touch via our contact form

Visual Guide

Related Products

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the milling process? A Guide to Shaping & Particle Reduction

- Why are high-power ultrasonic homogenizers essential for liquid metal nanodroplets? Overcome Surface Tension Barriers

- Why have we used ball milling for materials? Achieve Precise Particle Size Reduction and Material Synthesis

- What is the purpose of grinding bulk solid catalysts into fine powder? Maximize Surface Area and Catalytic Efficiency

- What are the negative impacts of excessive grinding time for Li3V2(PO4)3? Prevent WC Contamination & Lattice Defects

- What is a hammer mill used for in pharmaceuticals? Achieve Precise Particle Size Control for Better Drug Efficacy

- What role does a vibration mill play in Zeta potential measurements? Prepare Ultrafine Samples for Accurate Analysis

- What is the difference between a bead mill and a ball mill? A Guide to Choosing the Right Grinding Technology