At their core, ultra-low temperature (ULT) freezers are defined by three categories of features: advanced refrigeration systems for precise temperature control, comprehensive security and monitoring to protect samples, and robust construction designed for long-term reliability in demanding environments. These systems are engineered to maintain temperatures as low as -86°C, ensuring the viability of sensitive biological materials.

The collection of features in a ULT freezer is not a simple checklist. It is an integrated system designed for one primary purpose: to create an exceptionally stable and secure environment that guarantees the integrity of invaluable and often irreplaceable biological samples.

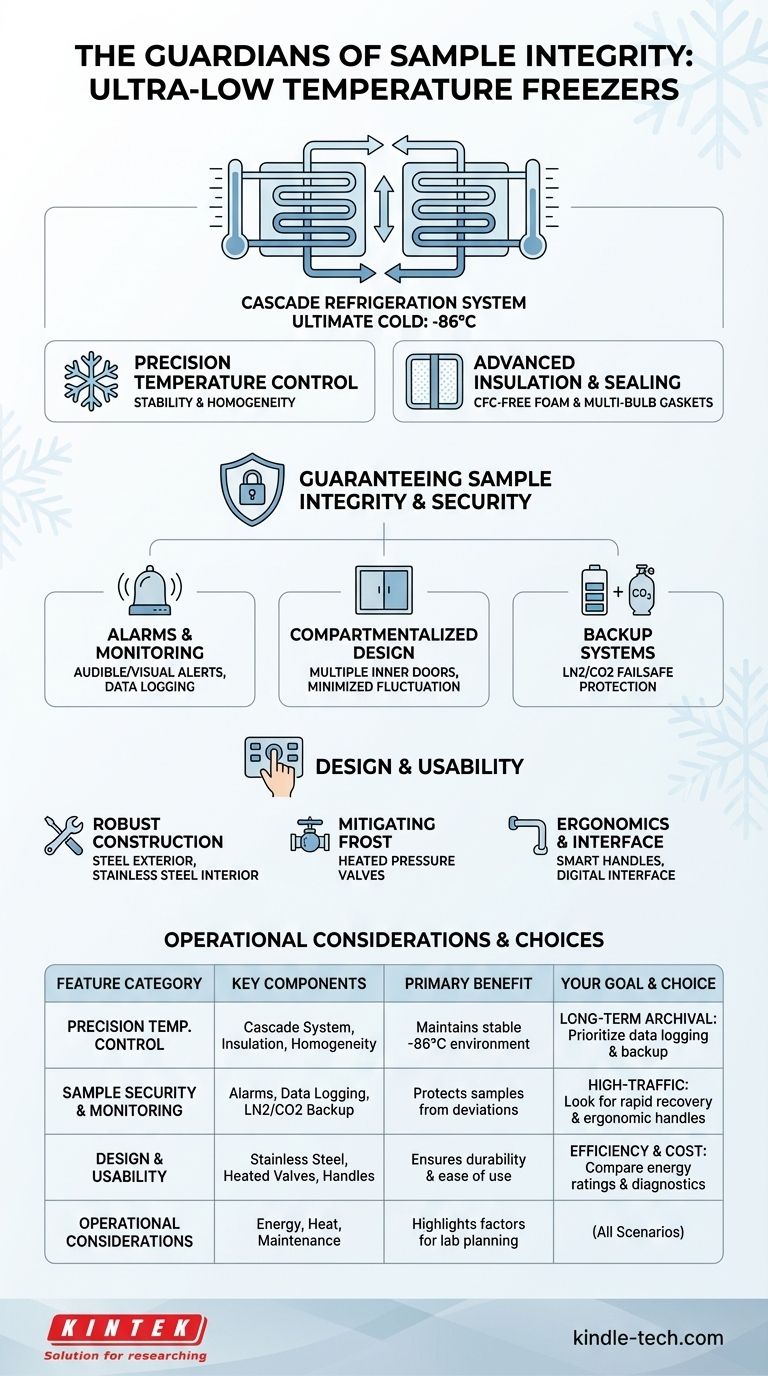

The Foundation: Precision Temperature Control

The most fundamental feature of a ULT freezer is its ability to create and maintain an extremely cold, stable environment. This is achieved through a combination of powerful cooling technology and superior physical design.

The Cascade Refrigeration System

A ULT freezer doesn't use a single cooling mechanism. It uses a cascade refrigeration system, which involves two separate refrigeration circuits working in tandem.

The first circuit cools the second, allowing the second circuit to achieve far lower temperatures than a single system could alone. This is the core technology that enables temperatures to reach -86°C.

Key Performance Metrics

Beyond just reaching a low temperature, a freezer's performance is measured by its stability. Key metrics include quick temperature pull-down (how fast it gets cold initially) and rapid temperature recovery after a door opening.

Another critical factor is temperature homogeneity, which ensures that the temperature is uniform throughout the entire internal chamber, preventing dangerous warm spots.

Advanced Insulation and Sealing

To maintain these extreme temperatures efficiently, ULT freezers use thick, CFC-free foam insulation.

The door seal is also critical. Many models use multi-bulb gaskets to create multiple points of contact, ensuring a tight seal that prevents cold air from escaping and ambient air from entering.

Guaranteeing Sample Integrity and Security

Because the samples stored in ULT freezers are often priceless, protecting them from equipment failure or temperature deviations is a top priority.

Alarms and Monitoring Systems

Virtually all ULT freezers include built-in audible and visual alarms that activate if the temperature deviates from the set point.

More advanced models also feature data logging capabilities to continuously monitor and record temperature data, providing a complete history for regulatory compliance and quality control. Optional features like phone dialers can alert personnel of a problem remotely.

Compartmentalized Interior Design

Opening the main door can cause a significant temperature fluctuation. To minimize this, ULT freezers have multiple separate internal storage compartments, each protected by its own insulated inner door.

This design allows a user to access one specific section without exposing the entire freezer's contents to warmer ambient air, drastically improving temperature recovery time.

Backup Systems for Failsafe Protection

For the most critical samples, backup systems provide an essential layer of security. In the event of a power failure, an LN2 (liquid nitrogen) or CO2 (carbon dioxide) backup system can be deployed to keep the freezer chamber cold for an extended period.

Understanding the Design and Usability

The physical design of a ULT freezer is engineered for durability, reliability, and ease of use in a laboratory setting.

Robust Physical Construction

ULT freezers are built to last. They typically feature robust steel construction for the exterior and stainless steel interiors for durability and ease of cleaning.

Mitigating Frost and Ice

Ice buildup is a constant challenge. Features like heated pressure release valves warm the air vent just enough to make opening the door easier by breaking the powerful vacuum seal created by the cold. This, along with tight door seals, helps reduce frost formation.

Ergonomics and User Interface

Modern freezers include user-friendly digital interfaces for setting and monitoring temperature. Features like ergonomic smart handles require less force to open the door, reducing physical strain on lab personnel.

Common Pitfalls and Operational Considerations

While their features are advanced, operating a ULT freezer involves understanding key trade-offs and requirements that are often overlooked.

High Energy Consumption

Cascade refrigeration systems are powerful and consume a significant amount of electricity. This is a major operational cost that must be factored into any lab's budget.

Heat Output and Ventilation

These freezers work by removing heat from the inside and exhausting it into the room. They generate substantial heat and require placement in a well-ventilated area with adequate clearance to prevent overheating.

The Need for Regular Maintenance

Proper function depends on routine care. This includes regularly clearing away any ice or frost buildup from the interior and gaskets, as well as cleaning the refrigeration system's filters to ensure proper airflow and cooling efficiency.

Making the Right Choice for Your Goal

The most important features depend entirely on your lab's specific application and workflow.

- If your primary focus is long-term archival of critical samples: Prioritize units with robust data logging, remote alarm capabilities, and an integrated LN2 or CO2 backup system.

- If your primary focus is high-traffic daily access: Look for rapid temperature recovery rates, multiple inner doors, and ergonomic handles to withstand frequent use.

- If your primary focus is operational efficiency and cost: Compare energy consumption ratings and look for models with on-board system diagnostics to simplify maintenance.

Ultimately, understanding these key features empowers you to select a freezer that will serve as a reliable guardian for your most critical work.

Summary Table:

| Feature Category | Key Components | Primary Benefit |

|---|---|---|

| Precision Temperature Control | Cascade Refrigeration System, Advanced Insulation, Temperature Homogeneity | Maintains stable -86°C environment for sample integrity |

| Sample Security & Monitoring | Multi-level Alarms, Data Logging, LN2/CO2 Backup Systems | Protects invaluable samples from temperature deviations |

| Design & Usability | Stainless Steel Interior, Heated Pressure Valves, Ergonomic Handles | Ensures durability and ease of use in lab environments |

| Operational Considerations | Energy Consumption, Heat Output, Maintenance Requirements | Highlights important factors for lab planning and budgeting |

Ready to secure your critical samples with a reliable ultra-low temperature freezer?

At KINTEK, we understand that your laboratory's success depends on preserving the integrity of sensitive biological materials. Our range of ULT freezers combines advanced temperature control, comprehensive security features, and robust construction to meet the demanding needs of research, clinical, and biobanking facilities.

Why choose KINTEK for your lab equipment needs?

- Precision Performance: Our freezers deliver exceptional temperature stability and rapid recovery times

- Unmatched Security: Advanced monitoring systems and backup options protect your invaluable samples

- Long-Term Reliability: Durable construction ensures consistent performance in high-use environments

- Expert Support: Our team provides personalized guidance to select the perfect solution for your specific workflow

Don't leave your sample integrity to chance—contact our experts today to discuss how KINTEK's ultra-low temperature freezers can enhance your laboratory's capabilities and safeguard your most important work.

Visual Guide

Related Products

- 108L Vertical Ultra Low Temperature ULT Freezer

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 308L Precision Ultra Low Temperature Freezer for Laboratory Applications

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 28L Compact Upright Ultra Low Temperature Freezer for Laboratory

People Also Ask

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C