At its core, a ball mill’s primary advantage is its exceptional capability to produce extremely fine, consistent powders from hard and abrasive materials. It achieves this through a simple, reliable mechanism that is adaptable to a wide range of industrial applications, from mineral processing and ceramics to pharmaceuticals and pyrotechnics. Its enclosed design also provides critical benefits for handling sensitive or hazardous substances safely.

The true value of a ball mill lies not in its speed, but in its reliability and versatility. It is an indispensable tool for achieving a very fine particle size, especially when working with difficult materials or when process containment is a priority.

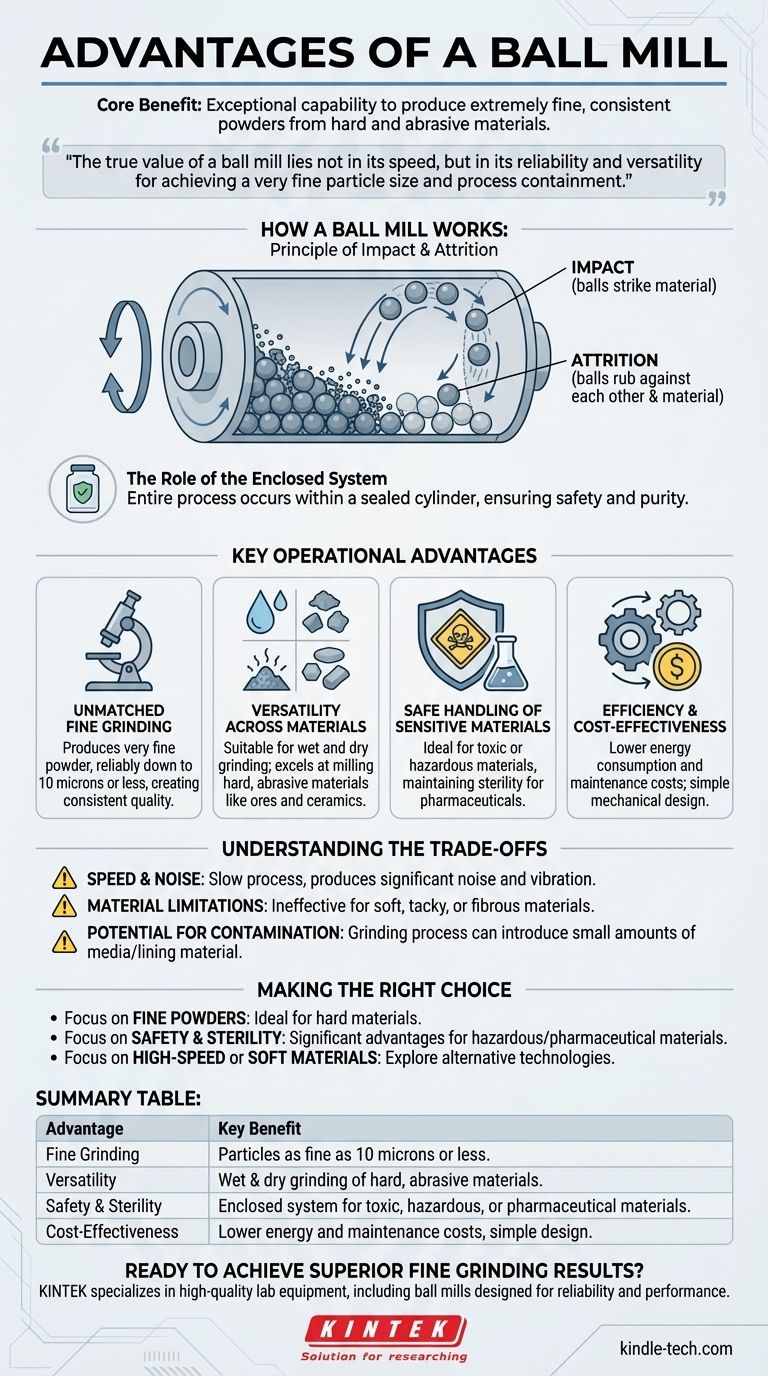

How a Ball Mill Works

To understand its advantages, it's essential to first grasp its fundamental operating principle. A ball mill is a simple device with powerful results.

The Principle of Impact and Attrition

A ball mill is a hollow cylinder that rotates on its axis. This cylinder is filled with the material to be ground, along with a grinding medium—typically steel or ceramic balls.

As the cylinder rotates, the balls are lifted up the side and then cascade down. This action grinds the material in two ways: through impact (as balls fall and strike the material) and attrition (as balls rub against each other and the material).

The Role of the Enclosed System

The entire process occurs within this sealed cylinder. This simple fact is the source of several of its most significant advantages, particularly regarding safety and purity.

Key Operational Advantages

The simple design of the ball mill gives rise to several powerful benefits that make it a cornerstone of many industrial processes.

Unmatched Fine Grinding Capability

The most cited advantage of a ball mill is its ability to produce a very fine powder. It can reliably reduce particle sizes to 10 microns or less, creating a consistent, high-quality product that is difficult to achieve with other methods.

Versatility Across Materials and Processes

Ball mills are suitable for both wet and dry grinding processes, adding to their flexibility. They excel at milling hard, abrasive materials like ores and ceramics that would quickly wear down other types of grinders.

Safe Handling of Sensitive Materials

Because the entire process occurs in a sealed container, ball mills are ideal for milling toxic or hazardous materials, preventing exposure to operators and the environment.

This same enclosed system allows for maintaining sterility, a critical requirement in the manufacturing of pharmaceutical products like parenteral and ophthalmic drugs.

Efficiency and Cost-Effectiveness

Compared to other grinding technologies, ball mills often have lower energy consumption and maintenance costs. Their simple mechanical design means there are fewer complex parts to fail, and they are generally easy to clean and operate with a minimal installation footprint.

Understanding the Trade-offs

No technology is perfect, and a ball mill's strengths come with inherent limitations. Acknowledging these is key to making an informed decision.

Speed and Noise Considerations

Ball milling is a slow process. Achieving the desired fineness can take a significant amount of time, making it less suitable for high-throughput applications where speed is the primary concern. The tumbling action also produces considerable noise and vibration.

Material Limitations

Ball mills are ineffective for processing soft, tacky, or fibrous materials. These substances tend to coat the grinding media or agglomerate rather than breaking down under impact and attrition.

The Potential for Contamination

While the enclosed system protects against external contaminants, the grinding process itself can be a source of contamination. The constant wear on the grinding balls and the inner lining of the cylinder can introduce small amounts of material into the final product, which may be unacceptable for certain high-purity applications.

Making the Right Choice for Your Goal

Selecting a ball mill depends entirely on balancing its powerful advantages against its specific limitations for your application.

- If your primary focus is producing extremely fine, consistent powders from hard materials: A ball mill is an ideal and reliable choice that consistently delivers high-quality results.

- If your primary focus is safety and sterility: The enclosed system of a ball mill offers significant advantages for processing toxic, hazardous, or pharmaceutical-grade materials.

- If your primary focus is high-speed processing or milling soft, fibrous materials: You should explore alternative grinding technologies better suited for those specific requirements.

Ultimately, the ball mill remains a trusted industrial workhorse because it performs its core function—fine grinding of difficult materials—with exceptional reliability.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Fine Grinding | Produces particles as fine as 10 microns or less. |

| Versatility | Suitable for both wet and dry grinding of hard, abrasive materials. |

| Safety & Sterility | Enclosed system for handling toxic, hazardous, or pharmaceutical materials. |

| Cost-Effectiveness | Lower energy consumption and maintenance costs with a simple design. |

Ready to achieve superior fine grinding results in your lab?

KINTEK specializes in high-quality lab equipment, including ball mills designed for reliability and performance. Whether you're processing hard minerals, ceramics, or sensitive pharmaceutical compounds, our solutions are built to meet your precise needs for particle size reduction, safety, and efficiency.

Contact our experts today to find the perfect ball mill for your application and discover how KINTEK can enhance your laboratory's capabilities.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the primary function of a planetary ball mill in Fe-Ni alloy prep? Master Mechanical Alloying Efficiency

- What industries use ball mills? A Guide to Grinding Applications in Mining, Cement, and More

- What is the role of a high-energy ball mill in CoCr composite mixing? Unlock Superior Structural Refinement

- What role does a high-energy ball mill play in Pt/Pd alloy metallurgy? Unlock Superior Catalytic & Mechanical Power

- What is the function of high-energy ball milling for Ti-3Al-2.5V master alloys? Optimize Particle Size and Diffusion

- What is the role of a planetary ball mill in preparing Cu-doped TiO2? Optimize Your Solid-State Synthesis

- What is the primary function of a planetary ball mill in tantalum oxyfluoride prep? Master High-Energy Dispersion

- What is the primary function of a planetary ball mill in graphite regeneration? Enhance Recycled Battery Capacity