The primary advantages of a sieving machine are its ability to deliver highly accurate, repeatable, and efficient particle size analysis. By automating the separation process, these machines eliminate the inconsistencies of manual methods and ensure that materials meet precise quality control standards, leveraging durable, high-quality components for reliable performance.

The true value of a sieving machine isn't just separating particles; it's the standardization of that separation. This provides a reliable, data-driven foundation for quality control, research, and production processes that is impossible to achieve by hand.

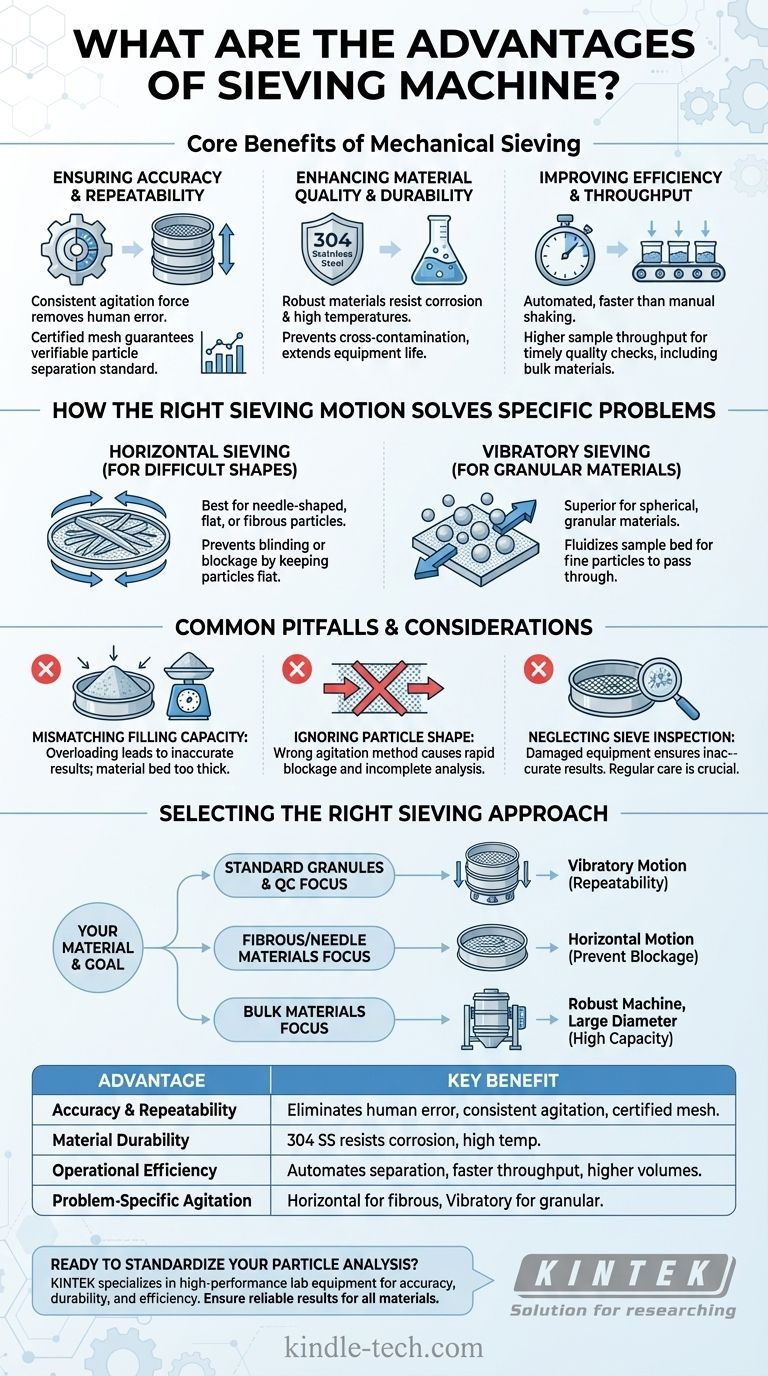

The Core Benefits of Mechanical Sieving

Modern sieving machines are engineered to provide definitive advantages over manual techniques, centering on precision, durability, and operational efficiency.

Ensuring Accuracy and Repeatability

A sieving machine provides a consistent agitation force and duration for every test. This removes the variable of human error, ensuring that results from different batches or operators are directly comparable.

The use of certified, precision-woven mesh with exact aperture sizes, from several millimeters down to a few microns, guarantees that particle separation is based on a verifiable standard.

Enhancing Material Quality and Durability

High-quality machines utilize robust materials like 304 stainless steel. This provides excellent corrosion resistance and chemical stability, making them suitable for a wide range of materials.

This durability also translates to high-temperature resistance and easy cleaning, preventing cross-contamination between samples and extending the life of the equipment.

Improving Efficiency and Throughput

Automated sieving is significantly faster than manual shaking, allowing for higher sample throughput. This is critical in production environments where timely quality checks are essential.

Certain designs also accommodate larger sieve stacks and higher sample volumes, enabling the analysis of bulk materials like construction aggregates in a single, efficient run.

How the Right Sieving Motion Solves Specific Problems

The method of agitation is not a minor detail; it is a critical factor that determines the effectiveness of the separation for different types of materials.

The Importance of Agitation Method

The goal of the machine's movement is to give each particle multiple opportunities to pass through a sieve aperture. The optimal motion depends entirely on the particle's shape and size.

Horizontal Sieving for Difficult Shapes

A horizontal sieving motion is exceptionally advantageous for particles that are needle-shaped, flat, long, or fibrous.

This circular movement keeps the particles oriented horizontally on the mesh. It prevents them from trying to pass through vertically, which would quickly lead to blinding or blockage of the sieve openings.

Vibratory Sieving for Granular Materials

For more spherical or granular materials, a three-dimensional vibratory or tapping motion is often superior. This movement lifts the material and reorients it, effectively fluidizing the sample bed and ensuring fine particles work their way down through the sieve stack.

Common Pitfalls and Considerations

To fully realize the advantages of a sieving machine, it is crucial to select the right device and operate it correctly.

Mismatching the Filling Capacity

The volume of material you analyze must be appropriate for the size of your sieves and the power of the machine.

Overloading a sieve stack leads to inaccurate results because the material bed is too thick for particles to effectively reach the mesh surface.

Ignoring Particle Shape

Using the wrong agitation method for your material is a common mistake. As noted, trying to separate fibrous material with a simple vertical tap shaker will result in rapid sieve blockage and an incomplete, inaccurate analysis.

Neglecting Sieve Inspection and Care

Even the best machine cannot compensate for damaged equipment. Sieves must be regularly inspected for dents, stretched mesh, or clogged apertures to ensure the accuracy of your results.

Selecting the Right Sieving Approach

Your choice should be dictated by your material and your analytical goal.

- If your primary focus is quality control of standard granules: A machine with a consistent vibratory or tapping motion is ideal for ensuring repeatability.

- If your primary focus is analyzing fibrous or needle-shaped materials: A horizontal sieving machine is essential to prevent mesh blockage and achieve an accurate separation.

- If your primary focus is processing large volumes of bulk material: Prioritize a robust machine with a large sieve diameter and high filling capacity.

Ultimately, the right sieving machine transforms particle analysis from a subjective task into a precise, reliable, and efficient scientific method.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Accuracy & Repeatability | Eliminates human error with consistent agitation and certified mesh. |

| Material Durability | 304 stainless steel construction resists corrosion and high temperatures. |

| Operational Efficiency | Automates separation for faster throughput and higher sample volumes. |

| Problem-Specific Agitation | Horizontal motion for fibrous materials; vibratory for granular materials. |

Ready to standardize your particle analysis and enhance your quality control?

KINTEK specializes in high-performance lab equipment, including sieving machines designed for accuracy, durability, and efficiency. Whether you're in quality control, research, or production, our solutions ensure reliable, repeatable results for a wide range of materials.

Contact us today to find the perfect sieving solution for your specific needs and let our experts help you optimize your processes. Get in touch now!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What is the machine used for sieve? Automate Your Particle Analysis with a Sieve Shaker

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- What is a sieve shaker used in a laboratory? Automate Particle Size Analysis for Accurate Results

- What is the role of crushing and sieving systems in wheat straw pretreatment? Maximize Sugar Yield through Particle Sizing

- What is the disadvantage of sieve shaker? Key Limitations in Particle Size Analysis

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability

- What is a shaking machine for wet sieving? Achieve Accurate Particle Size Analysis for Fine Powders

- What is a vibrating sieve? A Precision Tool for Particle Size Analysis