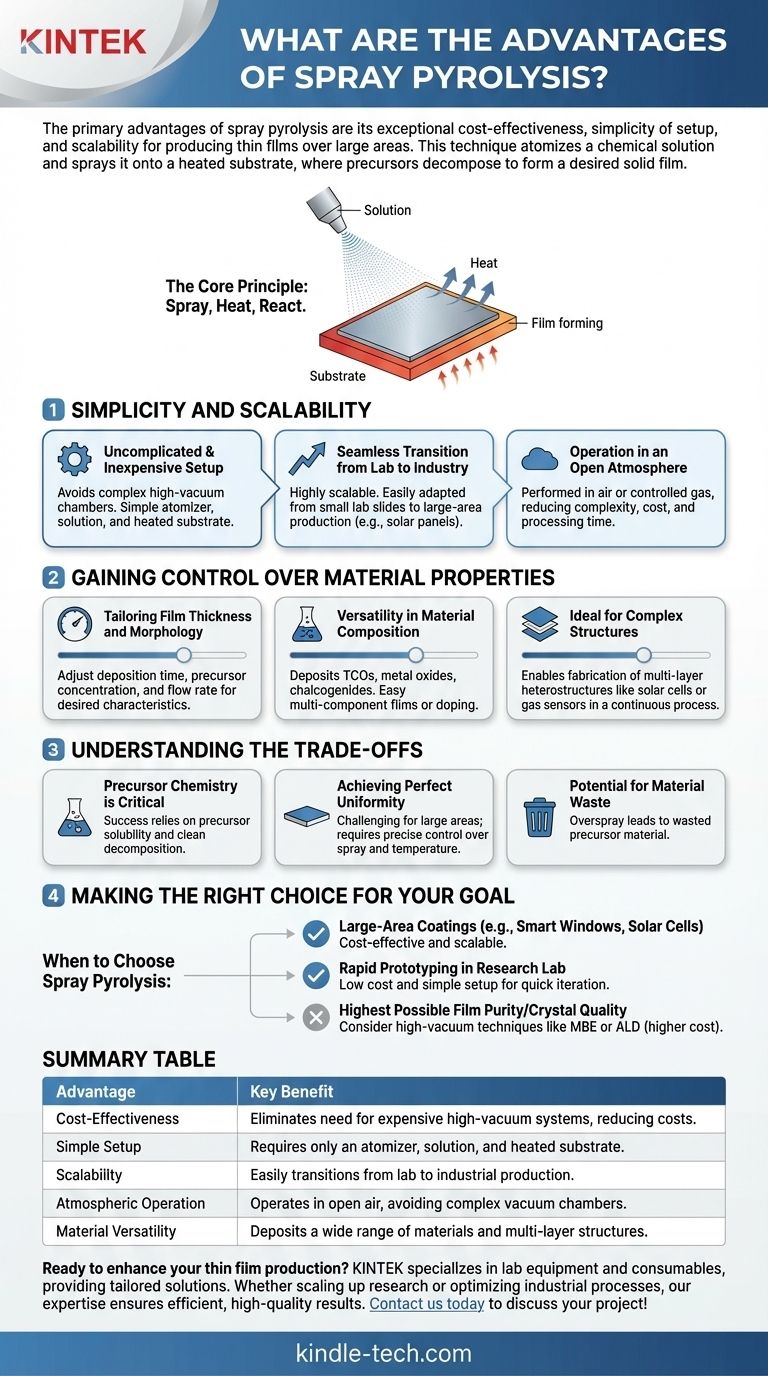

The primary advantages of spray pyrolysis are its exceptional cost-effectiveness, simplicity of setup, and scalability for producing thin films over large areas. This technique atomizes a chemical solution and sprays it onto a heated substrate, where the precursors decompose and react to form a desired solid film, making it a highly practical method for numerous electronic and material science applications.

Spray pyrolysis stands out as a powerful deposition technique because it elegantly bypasses the need for high vacuum and complex machinery. This makes it an accessible and economically viable choice for moving from laboratory research to industrial-scale production of functional thin films.

The Core Principle: Simplicity and Scalability

Spray pyrolysis operates on a straightforward principle: spray, heat, react. This inherent simplicity is the source of its most significant advantages, allowing for rapid and efficient film deposition without the overhead of more complex methods.

Uncomplicated and Inexpensive Setup

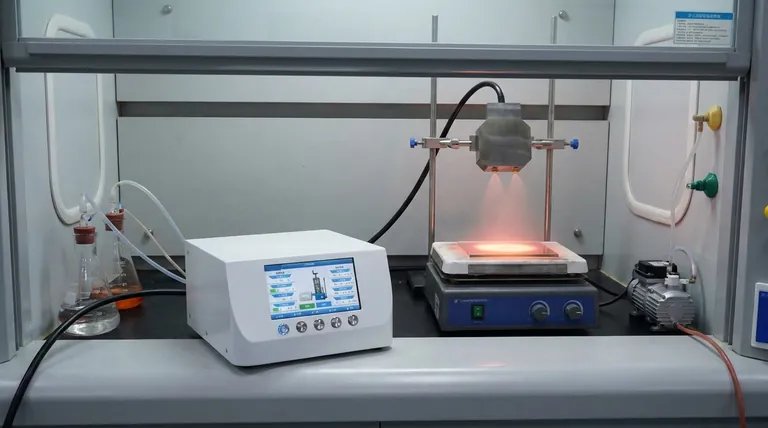

The equipment required for spray pyrolysis is relatively simple. It primarily consists of an atomizer (like a perfume sprayer or ultrasonic nozzle), a precursor solution, and a heated substrate. This avoids the need for expensive high-vacuum chambers common in techniques like sputtering or chemical vapor deposition (CVD).

Seamless Transition from Lab to Industry

The process is highly scalable. What works on a small glass slide in a research lab can be adapted to coat large-area surfaces, such as architectural glass or solar panels, by using an array of nozzles on an industrial line. This direct scalability is a major advantage for commercialization.

Operation in an Open Atmosphere

Unlike vacuum-based techniques, spray pyrolysis is typically performed in air or a controlled gas environment at atmospheric pressure. This drastically reduces equipment complexity, cost, and processing time, as there is no need to pump down a vacuum chamber between samples.

Gaining Control Over Material Properties

While simple in principle, spray pyrolysis offers a surprising degree of control over the final film's characteristics. By manipulating key parameters, researchers and engineers can fine-tune the material for specific applications.

Tailoring Film Thickness and Morphology

The thickness of the deposited film is easily controlled by adjusting the deposition time, precursor concentration, or solution flow rate. Furthermore, by changing the substrate temperature or solvent properties, one can influence the film's morphology—from dense and smooth to porous and textured.

Versatility in Material Composition

The technique is remarkably versatile, capable of depositing a wide range of materials, including transparent conducting oxides (TCOs), metal oxides, chalcogenides, and more. Creating multi-component films or doping a material is as simple as mixing the desired precursor salts into the initial spray solution.

Ideal for Complex Structures

The ability to easily change spray solutions makes it well-suited for creating multi-layer heterostructures. One layer can be deposited, followed immediately by another from a different solution, enabling the fabrication of complex devices like solar cells or gas sensors in a continuous process.

Understanding the Trade-offs

No technique is perfect, and objectivity requires acknowledging the limitations of spray pyrolysis. Understanding these challenges is key to using the method effectively.

Precursor Chemistry is Critical

The success of the process heavily relies on the "sprayability" of the precursor solution and its decomposition behavior. Precursors must be soluble in a suitable solvent and must decompose cleanly at the desired temperature to form the correct material phase without leaving behind unwanted residues.

Achieving Perfect Uniformity

While scalable, achieving perfectly uniform film thickness and properties over very large areas can be challenging. It requires precise control over the spray pattern, droplet size distribution, and temperature consistency across the entire substrate.

Potential for Material Waste

During the process, not all of the atomized spray lands on and adheres to the substrate. This "overspray" represents wasted precursor material, which can be a cost consideration, especially when using expensive chemicals.

Making the Right Choice for Your Goal

Spray pyrolysis is an excellent choice when the balance of cost, throughput, and performance is a key driver.

- If your primary focus is large-area coatings (e.g., smart windows, solar cells): Spray pyrolysis is one of the most cost-effective and scalable methods available for these applications.

- If your primary focus is rapid prototyping in a research lab: The low cost and simplicity of the setup allow for quick iteration and testing of new materials and device concepts.

- If your primary focus is achieving the highest possible film purity and crystal quality: High-vacuum techniques like molecular beam epitaxy (MBE) or atomic layer deposition (ALD) may be more suitable, albeit at a significantly higher cost.

Ultimately, spray pyrolysis provides a pragmatic and powerful pathway for creating functional thin films where industrial viability and cost are as important as performance.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Cost-Effectiveness | Eliminates need for expensive high-vacuum systems, reducing setup and operational costs. |

| Simple Setup | Requires only an atomizer, precursor solution, and heated substrate for easy implementation. |

| Scalability | Easily transitions from lab-scale research to industrial production for large-area coatings. |

| Atmospheric Operation | Operates in open air or controlled gas environments, avoiding complex vacuum chambers. |

| Material Versatility | Deposits a wide range of materials, including oxides, chalcogenides, and multi-layer structures. |

Ready to enhance your thin film production with spray pyrolysis? KINTEK specializes in lab equipment and consumables, providing tailored solutions for your laboratory's deposition needs. Whether you're scaling up research or optimizing industrial processes, our expertise ensures you achieve efficient, high-quality results. Contact us today to discuss how we can support your project!

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Thin-Layer Spectral Electrolysis Electrochemical Cell

People Also Ask

- Why is it necessary to use high-precision temperature-controlled heating furnaces? Secure Natural Fiber Integrity.

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- What is the hot press molding method? A Guide to Shaping Materials with Heat & Pressure

- What role does a benchtop hot press play in densifying composite cathodes? Achieve <10% Porosity with Thermo-Mechanical Flow

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing