In short, the primary advantages of using a sieve are its simplicity, low cost, and ability to produce highly accurate and reproducible results. This method allows for the rapid, direct physical separation of particles by size, making it a foundational and trusted technique in laboratories and industrial settings for quality control and material analysis.

Sieving stands as a cornerstone of particle analysis because it provides reliable, repeatable results with unmatched simplicity and cost-efficiency. While more advanced methods exist, sieving remains the optimal choice for a vast range of routine particle sizing and separation tasks.

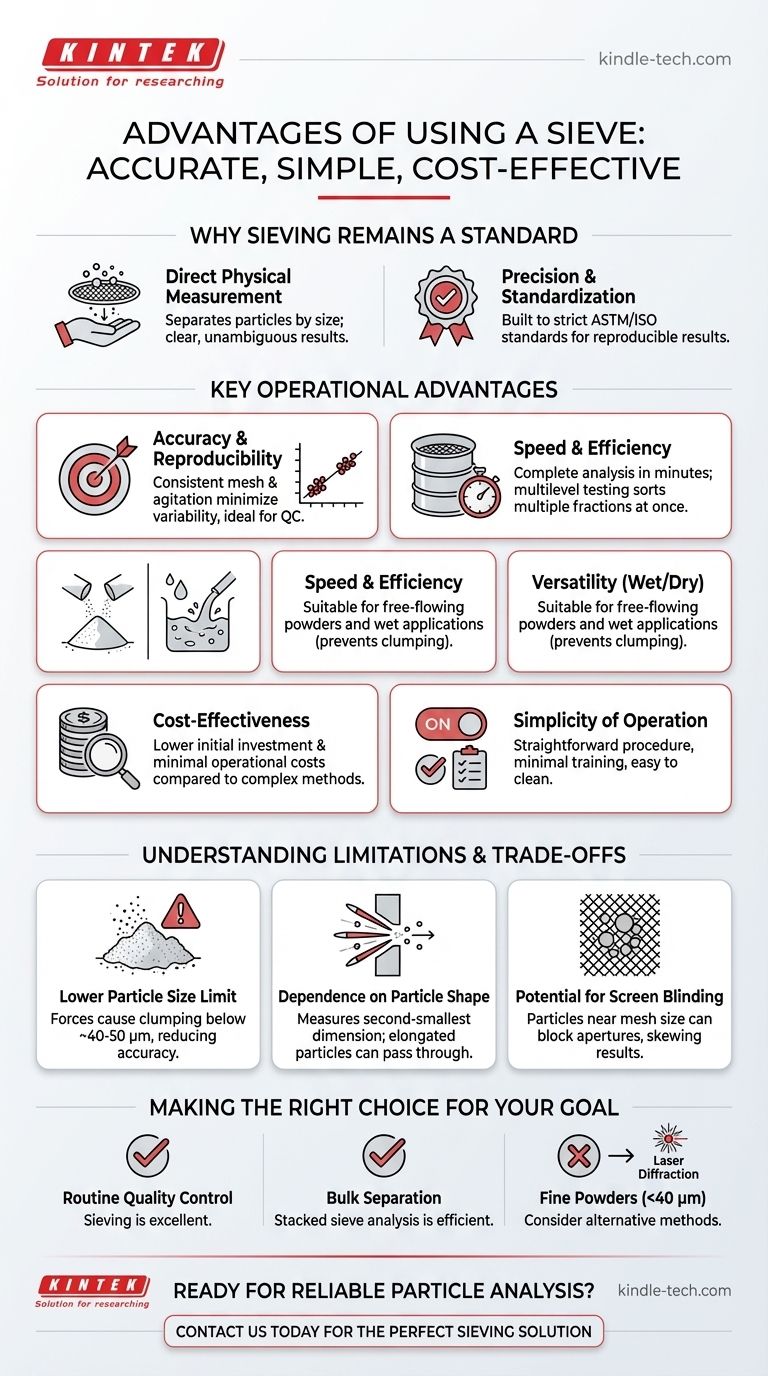

Why Sieving Remains a Standard Technique

Sieving is more than just a filtering process; it's a precise analytical method. Its enduring popularity comes from a unique combination of reliability, efficiency, and accessibility.

The Principle: Direct, Physical Measurement

At its core, sieving is a direct measurement. It physically separates particles based on whether they can pass through a precisely manufactured mesh aperture. This is fundamentally different from indirect methods (like laser diffraction) which infer size from other properties.

This directness provides a clear, unambiguous result that is easy to interpret and defend.

The Tool: Precision and Standardization

Modern test sieves are not simple screens. They are highly engineered instruments built to conform to strict national and international standards (such as ASTM and ISO).

This standardization ensures that a 100-micron sieve in one lab will perform identically to a 100-micron sieve in another, guaranteeing reproducible results across different sites and times.

Key Operational Advantages

In practice, sieving delivers several key benefits that make it the preferred method for many applications.

Accuracy and Reproducibility

When performed correctly, especially with an automated sieve shaker, the process is exceptionally repeatable. The combination of a fixed mesh size and a consistent agitation motion (such as a 3-D throwing action) minimizes variability.

This makes sieving ideal for routine quality control, where consistency is paramount.

Speed and Efficiency

Modern sieve shakers can complete an analysis in minutes. Furthermore, sieves can be stacked in a "tower," allowing a sample to be sorted into multiple size fractions simultaneously.

This multilevel testing provides a complete particle size distribution curve eficiênciaquickly and with a single run.

Versatility for Wet and Dry Sieving

Sieving can be performed on dry, free-flowing powders or adapted for "wet sieving." Wetting agents can be used to wash fine particles through the mesh, preventing clumping and screen blinding, which is especially useful for materials under 75 microns.

Cost-Effectiveness

Compared to more complex particle analysis technologies, the initial investment for a set of certified sieves and a shaker is significantly lower.

Operational costs are also minimal, as the primary requirements are labor and occasional sieve verification or replacement.

Simplicity of Operation

The procedure for sieve analysis is straightforward and does not require extensive operator training. The small footprint of the equipment and ease of cleaning, particularly for smaller sieve frames, add to its practical appeal.

Understanding the Trade-offs and Limitations

No method is perfect for every scenario. To use sieving effectively, you must understand its practical limitations.

The Lower Particle Size Limit

Sieving becomes less practical and accurate for extremely fine powders. As particles get smaller (typically below 40-50 µm), forces like static electricity and cohesion cause them to agglomerate, or "clump."

This clumping prevents them from passing through the mesh, leading to inaccurate results. At this scale, other methods like laser diffraction or air jet sieving are often more appropriate.

Dependence on Particle Shape

A sieve measures a particle's second-smallest dimension. This means long, needle-like or flat, flake-like particles can pass through a mesh aperture end-on or sideways, even if their longest dimension is much larger than the mesh opening.

This is a critical factor to consider, as the results reflect a dimensional sorting, not necessarily one based on mass or volume.

Potential for Screen Blinding

During dry sieving, particles that are very close in size to the mesh openings can become lodged in the apertures, a phenomenon known as "blinding." This blocks the screen and skews the results, requiring a pause to clean the sieve.

Making the Right Choice for Your Goal

To determine if sieving is the right method, consider your primary objective.

- If your primary focus is routine quality control and process verification: Sieving is an excellent choice due to its low cost, high reproducibility, and established methodology.

- If your primary focus is physically separating bulk material into different size fractions: Stacked sieve analysis is an exceptionally efficient and direct method for this type of sorting.

- If your primary focus is high-resolution analysis of very fine powders (<40 µm): You should investigate alternative methods like laser diffraction, as sieving loses accuracy and efficiency at these scales.

By understanding its distinct advantages and practical limits, you can confidently leverage sieving as a foundational tool in your material analysis toolkit.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Accuracy & Reproducibility | Direct physical measurement with standardized sieves for consistent results. |

| Cost-Effectiveness | Lower initial investment and operational costs compared to advanced methods. |

| Speed & Efficiency | Rapid analysis with multilevel testing for complete size distribution. |

| Versatility | Suitable for both dry and wet sieving applications. |

| Simplicity | Easy to operate with minimal training required. |

Ready to enhance your lab's particle analysis with reliable, cost-effective sieving?

KINTEK specializes in high-quality lab equipment and consumables, including precision test sieves and sieve shakers designed for accuracy and durability. Our solutions are trusted by laboratories worldwide for routine quality control and material separation tasks.

Contact us today to find the perfect sieving solution for your specific needs and ensure reproducible results in your lab!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis

- How is a vibratory sieve shaker used in the particle size analysis of mechanically alloyed powders? Expert Guide

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis