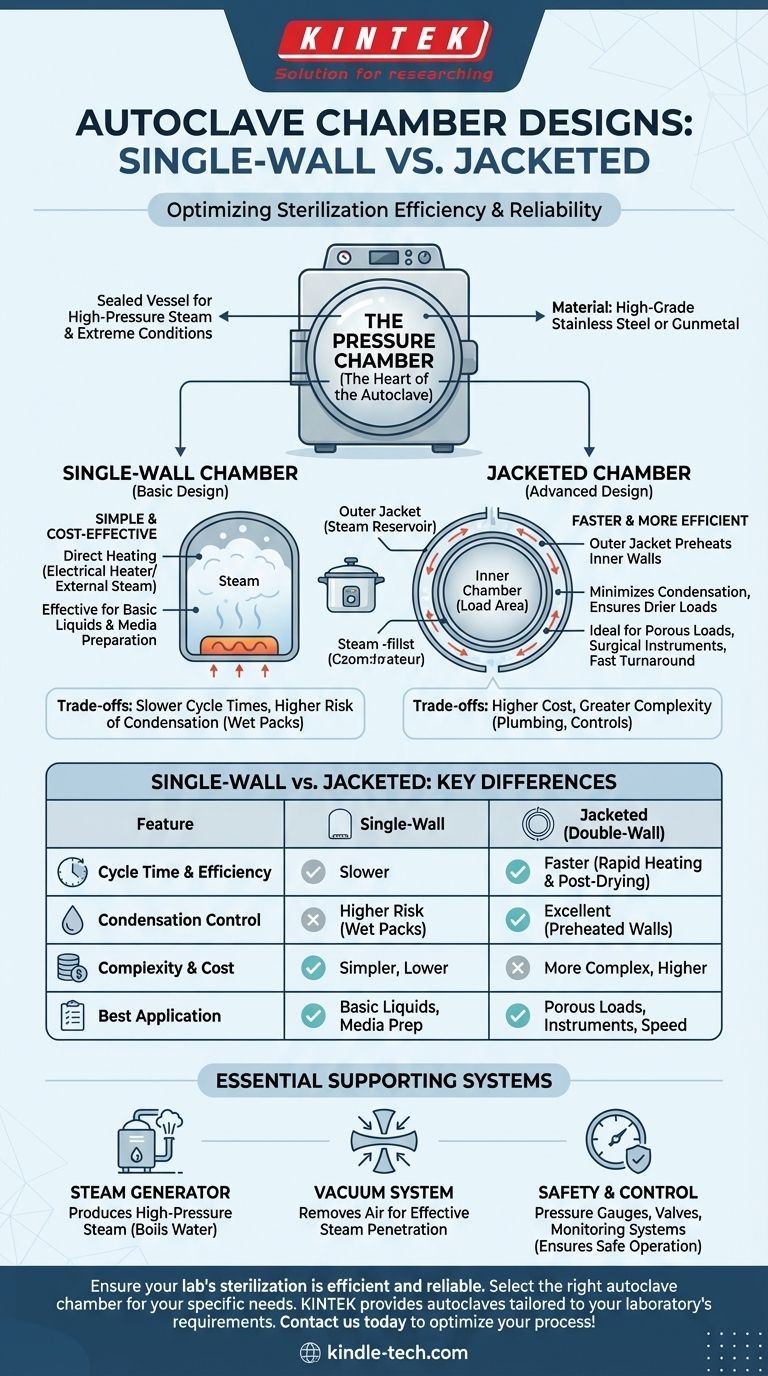

At the core of an autoclave's function is its pressure chamber, the primary vessel where sterilization takes place. While simple models use a single-walled chamber, most modern laboratory and hospital autoclaves feature a more sophisticated two-part system: an inner chamber that holds the items to be sterilized and a surrounding outer jacket. This design is not redundant; it is critical for achieving rapid, consistent, and effective sterilization.

The key distinction to understand is between a basic single-wall chamber and an advanced double-wall (jacketed) chamber. The outer jacket acts as a high-temperature steam reservoir, preheating the inner chamber to reduce condensation, shorten cycle times, and ensure a more uniform sterilization environment.

The Fundamental Role of the Pressure Chamber

The chamber is the heart of the autoclave, engineered to withstand extreme conditions and facilitate the sterilization process.

The Primary Vessel

The chamber is a robust container, typically constructed from high-grade stainless steel or gunmetal. Its primary purpose is to create a sealed environment that can safely contain high-pressure steam at temperatures well above the boiling point of water.

Creating the Sterilization Environment

All components, from the door to the safety valves, work to support the chamber's function. The goal is to evacuate all air and allow high-temperature steam to penetrate every surface of the items placed inside, ensuring the deactivation of all microorganisms.

Single-Wall vs. Jacketed Chambers: The Critical Distinction

The configuration of the chamber walls directly impacts the autoclave's performance, efficiency, and suitability for different tasks.

The Single-Wall Chamber

The simplest design features a single-walled vessel. An electrical heater or external steam source heats the water within this chamber directly to create steam. This design is analogous to a common pressure cooker and is effective for basic applications.

The Jacketed (Double-Wall) Chamber

Most professional-grade autoclaves use a jacketed chamber. This consists of the main inner chamber where you place your load, which is completely surrounded by the outer jacket.

The Function of the Outer Jacket

The outer jacket is filled with steam before and during the sterilization cycle. This serves several critical purposes. It preheats the walls of the inner chamber, preventing cooler surfaces that cause steam to condense into water when the cycle begins. This leads to drier, more effective sterilization.

Understanding the Trade-offs

The choice between a single-wall and a jacketed design involves clear trade-offs in performance and complexity.

Cycle Time and Efficiency

Jacketed autoclaves are significantly faster. By keeping the chamber walls hot, the time needed to reach sterilization temperature is reduced, and post-cycle drying is more rapid.

Condensation and "Wet Packs"

A primary challenge in sterilization is preventing condensation, which can leave loads damp (a "wet pack") and compromise sterility. The heated walls of a jacketed chamber are the most effective defense against this problem, especially for porous materials like fabrics or complex instruments.

Cost and Complexity

A single-wall design is simpler, less expensive to manufacture, and easier to maintain. Jacketed systems involve more complex plumbing, steam traps, and control systems, which increases their initial cost and ongoing maintenance requirements.

Essential Supporting Systems

The chamber does not operate in isolation. It relies on a series of integrated systems to function correctly and safely.

The Steam Generator

This component, which can be an integrated electrical heater or an external steam line, boils water to produce the high-pressure steam required for sterilization.

The Vacuum System

More advanced autoclaves use a vacuum generator. Before introducing steam, this system actively removes air from the chamber. Removing air is crucial because air pockets can insulate items and prevent steam from making direct contact, leading to failed sterilization.

Safety and Control Mechanisms

A network of pressure gauges, safety valves, and control systems constantly monitors and manages the conditions within the chamber. These components ensure the unit operates within safe pressure limits and that the correct temperature is maintained for the required duration.

Making the Right Choice for Your Application

Selecting the appropriate autoclave design is crucial for ensuring reliable and compliant sterilization outcomes.

- If your primary focus is basic liquid sterilization or media preparation: A simpler, non-jacketed autoclave is often sufficient and more cost-effective.

- If your primary focus is sterilizing porous loads, surgical instruments, or ensuring fast turnaround times: A jacketed autoclave is essential for minimizing condensation and achieving efficient, reliable results.

Understanding the chamber's design is the first step toward ensuring your sterilization processes are both effective and efficient.

Summary Table:

| Chamber Type | Key Features | Best For |

|---|---|---|

| Single-Wall | Simple design, cost-effective, direct heating | Basic liquid sterilization, media preparation |

| Jacketed (Double-Wall) | Outer steam jacket, pre-heated walls, faster cycles, reduces condensation | Porous loads, surgical instruments, fast turnaround times |

Ensure your lab's sterilization is efficient and reliable. The right autoclave chamber design is critical for your specific applications, from preparing media to sterilizing complex instruments. KINTEK specializes in lab equipment and consumables, providing autoclaves tailored to your laboratory's needs. Our experts can help you select the perfect system for superior performance and compliance. Contact us today to optimize your sterilization process!

Visual Guide

Related Products

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What are the functions of an autoclave and alumina liner in LBE experiments? Protect Your Research & Data Integrity.

- What are the two types of autoclave used in the laboratory? Gravity vs. Pre-Vacuum Explained

- Why are the design pressure and temperature ranges of high-pressure autoclaves critical for biomass HTL processes?

- How does autoclave destroy bacteria? Harness the Power of Pressurized Steam for Sterility

- What is the benefit of autoclave? Achieve Rapid, Reliable Sterilization for Your Lab

- What is the principle of autoclave in microbiology? The Key to Complete Sterilization

- Why are silver or platinum liners utilized in GaN synthesis? Protecting Purity and Autoclave Integrity

- Why is the temperature of an autoclave 121? The Science of Reliable Sterilization