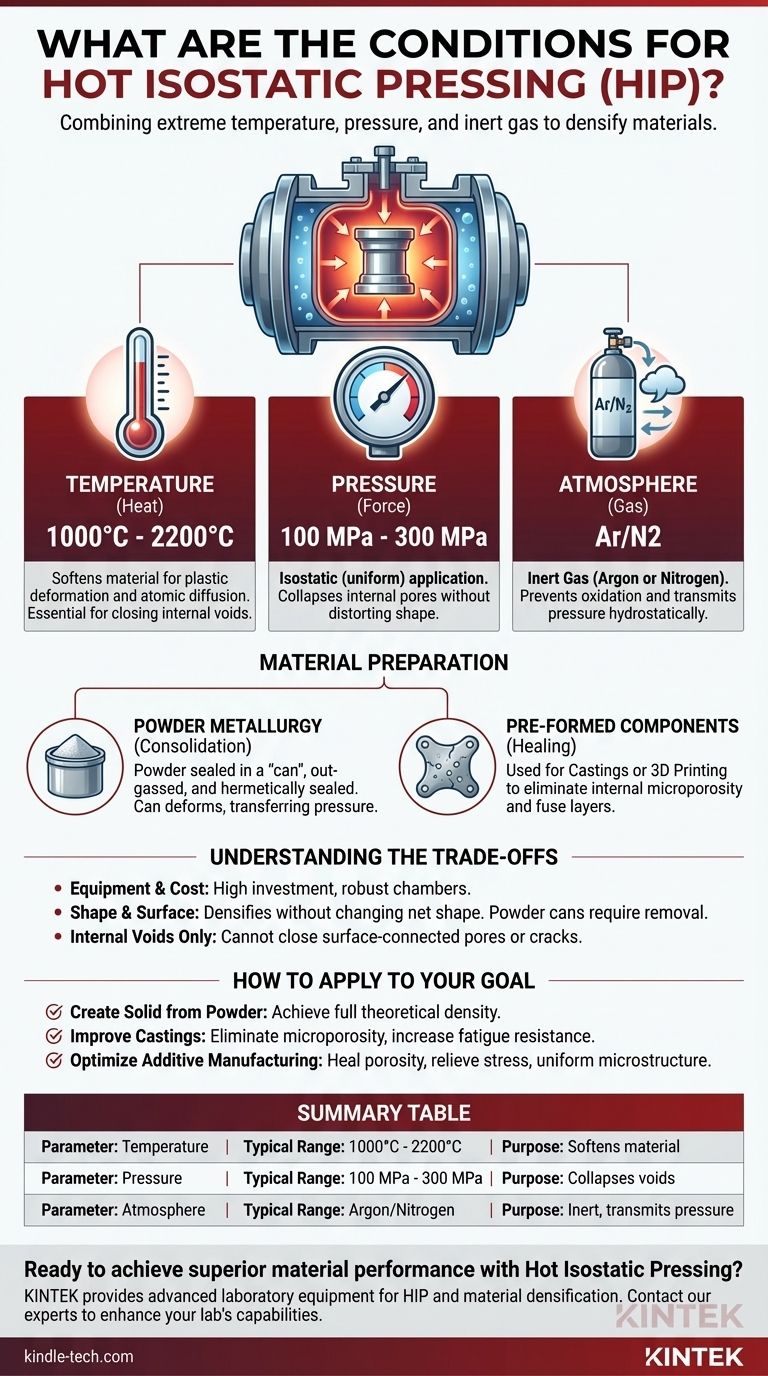

In short, Hot Isostatic Pressing (HIP) combines extremely high temperature, high pressure, and an inert gas atmosphere to densify materials. The process subjects a component to temperatures ranging from 1000°C to 2200°C and applies uniform, isostatic pressure of 100 to 300 MPa using a gas like Argon or Nitrogen.

Hot isostatic pressing is fundamentally a material consolidation process. Its precise conditions are designed to eliminate internal voids—like microporosity in castings or gaps between powder particles—to produce a fully dense component with superior mechanical properties.

The Core Parameters of HIP

To understand how HIP achieves its results, we must look at its three primary conditions: temperature, pressure, and atmosphere. Each plays a distinct and critical role.

The Role of Temperature

The process operates at very high temperatures, typically between 1000°C and 2200°C.

This intense heat is not meant to melt the material but to soften it. At these temperatures, the material's yield strength is significantly reduced, allowing it to deform plastically and enable atomic diffusion, which is essential for closing internal voids.

The Role of Pressure

Simultaneously, an extremely high pressure of 100 to 300 MPa is applied to the component.

This pressure is isostatic, meaning it is applied uniformly from all directions. This is the key to densifying the part without distorting its overall shape. The immense pressure physically collapses any internal pores or voids within the material.

The Role of Atmosphere

The pressure is transmitted through a high-purity inert gas, most commonly Argon or Nitrogen.

Using an inert gas is critical to prevent any chemical reactions, such as oxidation, with the component material at elevated temperatures. The gas acts as a perfectly uniform medium to transmit the pressure hydrostatically to every surface of the part.

Material Preparation and Requirements

The specific conditions of HIP depend on whether you are consolidating powder or densifying an existing solid part.

For Powder Metallurgy

When starting with metal or ceramic powders, they must first be sealed within a container, often called a "can."

This container is typically made of metal or glass. It is filled with the powder, out-gassed to create a vacuum, and then hermetically sealed. During the HIP cycle, the can deforms around the powder, transferring the isostatic pressure to consolidate it into a fully dense solid.

The powder itself must be free-flowing and easily compacted to ensure it packs uniformly within the can before the process begins.

For Pre-Formed Components

HIP is also widely used to heal defects in already-formed parts, such as those made by casting or additive manufacturing (3D printing).

In these cases, the goal is to eliminate internal microporosity from casting or to fuse layers and remove voids in 3D-printed parts. The component is simply placed in the HIP chamber, and the process closes any internal defects that are not connected to the surface.

Understanding the Trade-offs

While powerful, the HIP process involves specific considerations that are important for any technical evaluation.

Equipment and Cost

Hot isostatic pressing requires highly specialized and robust equipment. The cylindrical pressure chambers are precision-engineered to handle extreme conditions, making the process a significant investment compared to conventional heat treatment.

Shape and Surface Integrity

The process is designed to apply uniform pressure, which densifies the material without changing its net shape. This is a major advantage.

However, for powder consolidation, the "can" must be removed after the cycle, typically through machining or chemical etching.

Internal Defects Only

HIP is exceptionally effective at eliminating internal voids. It cannot, however, close any pores or cracks that are open to the surface, as the pressurizing gas will penetrate these defects, equalizing the pressure and preventing them from collapsing.

How to Apply This to Your Goal

The decision to use HIP should be driven by the final performance requirements of the component.

- If your primary focus is creating a solid from powder: HIP is the definitive process for achieving full theoretical density and creating high-performance components from powder materials.

- If your primary focus is improving critical castings: Use HIP to eliminate internal microporosity, which dramatically increases fatigue resistance, ductility, and overall part reliability.

- If your primary focus is optimizing additively manufactured parts: Apply HIP to heal porosity between layers, relieve internal thermal stresses, and create a uniform, robust microstructure.

Ultimately, hot isostatic pressing is the engineering solution for achieving maximum density and unlocking the full performance potential of advanced materials.

Summary Table:

| Parameter | Typical Range | Purpose |

|---|---|---|

| Temperature | 1000°C - 2200°C | Softens material for plastic deformation and atomic diffusion |

| Pressure | 100 MPa - 300 MPa | Uniformly collapses internal voids and pores (isostatic) |

| Atmosphere | Argon or Nitrogen | Inert gas prevents oxidation and transmits pressure uniformly |

Ready to achieve superior material performance with Hot Isostatic Pressing?

KINTEK specializes in providing advanced laboratory equipment and consumables to support your HIP and material densification processes. Whether you are working with powder metallurgy, optimizing castings, or improving additive manufacturing parts, our solutions help you eliminate internal defects and unlock full material potential.

Contact our experts today to discuss how we can enhance your lab's capabilities and drive your projects forward.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- When was hot isostatic pressing invented? The 1955 Breakthrough for Superior Material Integrity

- Why are Warm Isostatic Presses (WIP) necessary for solid-state batteries? Achieve Atomic-Level Contact

- Why is Hot Isostatic Pressing (HIP) Required for Additive Inconel 718? Achieve 100% Theoretical Density

- What is the working principle of hot isostatic pressing? Unlock Superior Material Density & Performance

- What is the sinter HIP process? Achieve Near-Perfect Density in a Single Cycle

- How does Hot Isostatic Pressing reduce porosity? Eliminate Internal Voids for Superior Material Density

- What is the hot isostatic process? Achieve Perfect Material Density for Critical Components

- What advantages does a warm isostatic press offer over a traditional uniaxial press for Li6PS5Cl electrolyte sheets?