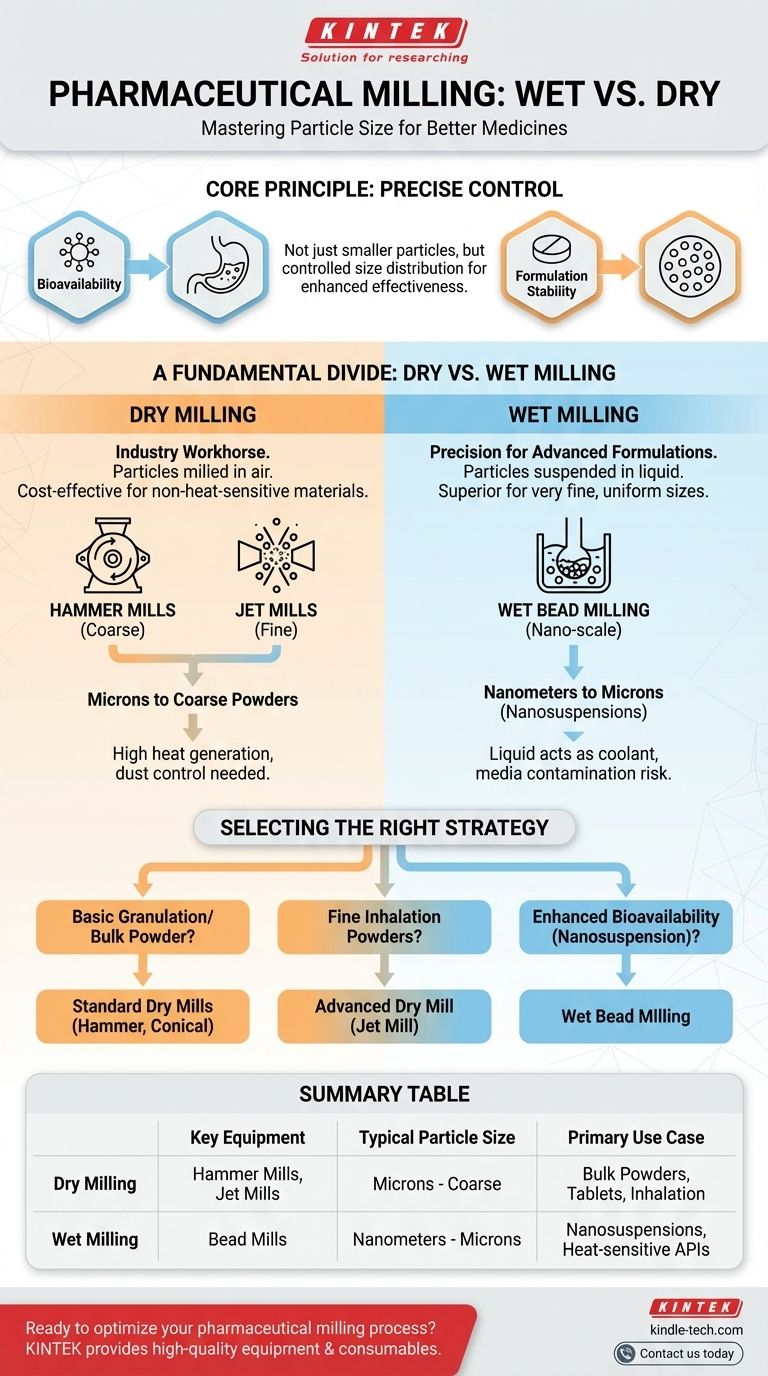

In the pharmaceutical industry, milling is broadly categorized by the medium used: wet milling, where particles are suspended in liquid, and dry milling, where they are not. The choice depends on the material's properties and the desired final particle size, which is a critical factor in determining a drug's effectiveness.

The central goal of pharmaceutical milling is not simply to make particles smaller, but to precisely control their size distribution. This control is essential for enhancing drug solubility, bioavailability, and overall therapeutic performance.

The Core Principle: Why Milling is Critical

Milling, or comminution, is the process of reducing the particle size of a solid substance. In pharmaceuticals, this is not just a preparatory step; it is a fundamental part of drug formulation.

The Link to Bioavailability

Many new drug compounds are poorly soluble in water. Reducing their particle size dramatically increases the surface area available for dissolution in the body, which can significantly improve their absorption and bioavailability.

Impact on Formulation Stability

Uniform particle size is crucial for creating stable and consistent formulations. It ensures even distribution of the Active Pharmaceutical Ingredient (API) in a tablet or suspension, leading to predictable and reliable dosing.

A Fundamental Divide: Wet vs. Dry Milling

The primary distinction in pharmaceutical milling techniques is whether the process occurs in a liquid suspension (wet) or in the air (dry).

Dry Milling: The Industry Workhorse

Dry milling is a common, cost-effective method for particle size reduction, especially for materials that are not heat-sensitive or prone to dust explosions.

It typically involves mechanical forces like impact, attrition (rubbing), or shearing. Common equipment includes hammer mills, which use swinging hammers for coarse grinding, and jet mills, which use high-velocity jets of air or gas to make particles collide with each other for fine grinding.

Wet Milling: Precision for Advanced Formulations

Wet milling involves dispersing the API in a liquid carrier, creating a slurry that is then milled. This technique is superior for achieving very fine and uniform particle sizes.

The most prominent example is wet bead milling. As noted in research, this method allows for precise control down to the nanometer scale, which is essential for developing modern drug delivery systems like nanosuspensions. The liquid medium helps dissipate heat and prevents issues like dust contamination.

Understanding the Trade-offs and Key Considerations

Choosing the right milling technique requires a careful analysis of the drug substance, the formulation goal, and processing constraints.

Material Properties and Heat Sensitivity

High-energy dry milling methods, like jet milling, can generate significant heat. This can degrade heat-sensitive APIs. Wet milling is often the superior choice for these compounds, as the liquid medium acts as an effective coolant.

Target Particle Size and Distribution

For basic powders used in tablets or capsules, dry methods like hammer or pin mills are often sufficient. To produce fine powders for inhalation, a jet mill is necessary. However, to create stable nanosuspensions for injectable or oral liquid dosage forms, wet bead milling is the industry standard.

Contamination and Process Safety

Dry milling of fine powders can create a significant dust explosion hazard and requires stringent containment measures. Wet milling inherently mitigates this risk. However, wet milling introduces the risk of media contamination from the grinding beads, which must be carefully managed.

Formulation and Downstream Processing

The output of the milling process directly impacts subsequent steps. Dry milling produces a powder that needs to be blended, granulated, or dissolved. Wet milling directly produces a suspension, which may be the final dosage form or require a further step like spray drying to be converted back into a solid.

Selecting the Right Milling Strategy

Your choice of milling technology should be directly aligned with the therapeutic objective and the properties of your drug molecule.

- If your primary focus is basic granulation or bulk powder for simple tablets: Standard dry methods like hammer or conical mills are efficient and cost-effective.

- If your primary focus is producing fine, micron-sized powders for inhalation products: An advanced dry method like a jet mill is the appropriate choice.

- If your primary focus is enhancing the bioavailability of a poorly soluble drug by creating a nanosuspension: Wet bead milling is the definitive technology to achieve the necessary particle size and stability.

Ultimately, mastering milling techniques empowers formulators to overcome drug delivery challenges and design more effective medicines.

Summary Table:

| Milling Type | Key Equipment | Typical Particle Size | Primary Use Case |

|---|---|---|---|

| Dry Milling | Hammer Mills, Jet Mills | Microns to Coarse Powders | Bulk powders, tablets, inhalation products |

| Wet Milling | Bead Mills | Nanometers to Microns | Nanosuspensions, heat-sensitive APIs, bioavailability enhancement |

Ready to optimize your pharmaceutical milling process? The right milling strategy is critical for drug solubility, bioavailability, and formulation success. KINTEK specializes in providing high-quality lab equipment and consumables for both wet and dry milling applications. Our experts can help you select the perfect solution for your API and formulation goals. Contact us today to discuss your specific needs and enhance your drug development process!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- Why use zirconia ball milling jars for SiC/ZTA composite powders? Ensure High Purity & Efficient Particle Refinement

- Why are zirconia (ZrO2) milling jars recommended for sulfide electrolytes? Ensure Purity in Li6PS5Cl Synthesis

- Why is a ball mill jar lined with Y-ZrO2 required for Na3PS4 synthesis? Ensuring Purity in Sulfide Electrolytes

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results

- Why are tungsten carbide grinding jars and balls preferred for high-purity lithium ceramic powders? Ensure Peak Purity.