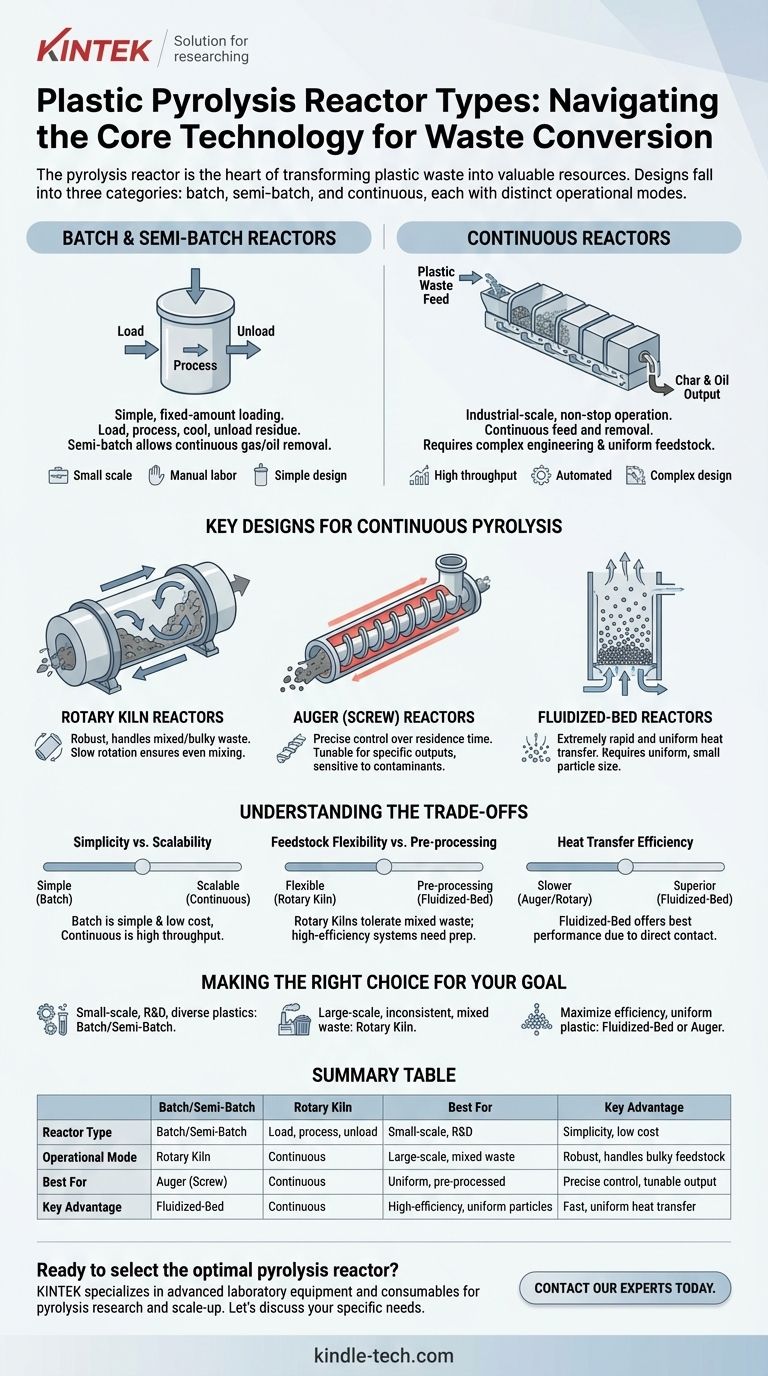

When converting plastic waste into valuable resources, the pyrolysis reactor is the core technology where the transformation happens. While numerous designs exist, they primarily fall into three categories based on their operational mode: batch, semi-batch, and continuous systems, with continuous reactors like rotary kilns, auger, and fluidized-bed designs being common for industrial applications.

The "best" type of pyrolysis reactor does not exist. The optimal choice depends entirely on balancing operational scale, the type and consistency of the plastic feedstock, and the desired efficiency of the heat transfer process.

The Core Operational Divide: Batch vs. Continuous

The most fundamental distinction between pyrolysis reactors is how they handle the plastic waste feed. This single choice dictates the scale, labor requirements, and overall workflow of the entire facility.

Batch and Semi-Batch Reactors

A batch reactor is the simplest design. A fixed amount of plastic waste is loaded into the chamber, sealed, heated to complete the pyrolysis process, and then cooled before the solid residue (char) is removed.

Semi-batch systems are similar but allow for the continuous removal of the gases and oils produced during the process, while the solid waste remains inside until the cycle is complete. These are often based on a fixed-bed design where the plastic remains stationary.

Continuous Reactors

Continuous reactors are designed for industrial-scale operations. Plastic waste is continuously fed into the reactor at one end and the resulting char is continuously removed from the other, allowing the system to run for long periods without shutdown.

This approach offers higher throughput and process consistency but requires more sophisticated engineering, automation, and uniform feedstock preparation.

Key Designs for Continuous Pyrolysis

Most innovation in pyrolysis technology focuses on continuous reactor designs, as they are essential for making the process economically viable at a large scale. The primary difference between them is the mechanism used to move and heat the material.

Rotary Kiln Reactors

A rotary kiln is a large, rotating cylindrical vessel inclined at a slight angle. As the kiln slowly rotates, the plastic waste tumbles and moves from the higher end to the lower end, ensuring it is mixed and heated evenly.

This design is robust and excellent at handling non-uniform, bulky, or mixed plastic waste with minimal pre-processing.

Auger (Screw) Reactors

An auger reactor, also known as a screw reactor, uses a large screw mechanism to transport plastic material through a heated tube. The speed of the screw provides precise control over how long the plastic stays in the reactor.

This precise control makes it possible to fine-tune the process for specific feedstocks and desired outputs, though it can be more sensitive to contaminants or large variations in plastic size.

Fluidized-Bed Reactors

In a fluidized-bed reactor, pre-shredded plastic particles are suspended by an upward flow of hot, inert gas. This creates a "fluid-like" bed of material where particles are vigorously mixed, resulting in extremely rapid and uniform heat transfer.

This is one of the most efficient reactor designs, but it is also the most complex. It demands very uniform, small particle sizes and is less tolerant of variations in feedstock.

Understanding the Trade-offs

Choosing a reactor involves navigating a series of critical engineering and economic trade-offs. There is no single solution that excels in all areas.

Simplicity vs. Scalability

Batch reactors offer simplicity and lower initial capital costs, making them ideal for research, pilot projects, or smaller community-level operations. However, their start-and-stop nature makes them inefficient for large-scale industrial production. Continuous reactors are complex and expensive but are the only viable option for high-throughput processing.

Feedstock Flexibility vs. Pre-processing

A key challenge in plastic recycling is the inconsistent nature of the waste. Rotary kilns are highly tolerant of mixed and poorly prepared feedstock. In contrast, high-efficiency systems like fluidized-bed reactors require extensive pre-processing, including shredding and drying, adding cost and complexity to the overall operation.

Heat Transfer Efficiency

The speed and uniformity of heat transfer directly impact the quality and consistency of the pyrolysis oil. Fluidized-bed reactors offer the best performance due to the direct contact between the hot gas and each plastic particle. Auger and rotary kiln reactors rely more on conduction and convection, which can be slower and less uniform.

Making the Right Choice for Your Goal

Your selection must be guided by the specific goals of your project, the nature of your available plastic waste, and your desired operational scale.

- If your primary focus is small-scale operations or testing diverse plastics: A batch or semi-batch reactor offers the most flexibility and the lowest barrier to entry.

- If your primary focus is large-scale industrial processing of inconsistent, mixed waste: A robust continuous system like a rotary kiln is often the most practical choice.

- If your primary focus is maximizing efficiency with uniform, pre-processed plastic: A continuous fluidized-bed or auger reactor provides superior heat transfer and process control.

Ultimately, the most effective reactor is the one that aligns its mechanical design with your specific feedstock characteristics and operational goals.

Summary Table:

| Reactor Type | Operational Mode | Best For | Key Advantage |

|---|---|---|---|

| Batch/Semi-Batch | Load, process, unload | Small-scale, R&D, testing | Simplicity, low cost |

| Rotary Kiln | Continuous | Large-scale, mixed/uniform waste | Robust, handles bulky feedstock |

| Auger (Screw) | Continuous | Uniform, pre-processed plastic | Precise control, tunable output |

| Fluidized-Bed | Continuous | High-efficiency, uniform particles | Fast, uniform heat transfer |

Ready to select the optimal pyrolysis reactor for your plastic waste conversion project?

At KINTEK, we specialize in advanced laboratory equipment and consumables for pyrolysis research and scale-up. Whether you're testing feedstocks in a batch reactor or scaling up to a continuous system, our expertise and reliable solutions help you achieve efficient, consistent results. Let's discuss your specific needs and find the right reactor technology for your goals.

Contact our experts today to get started!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

People Also Ask

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields