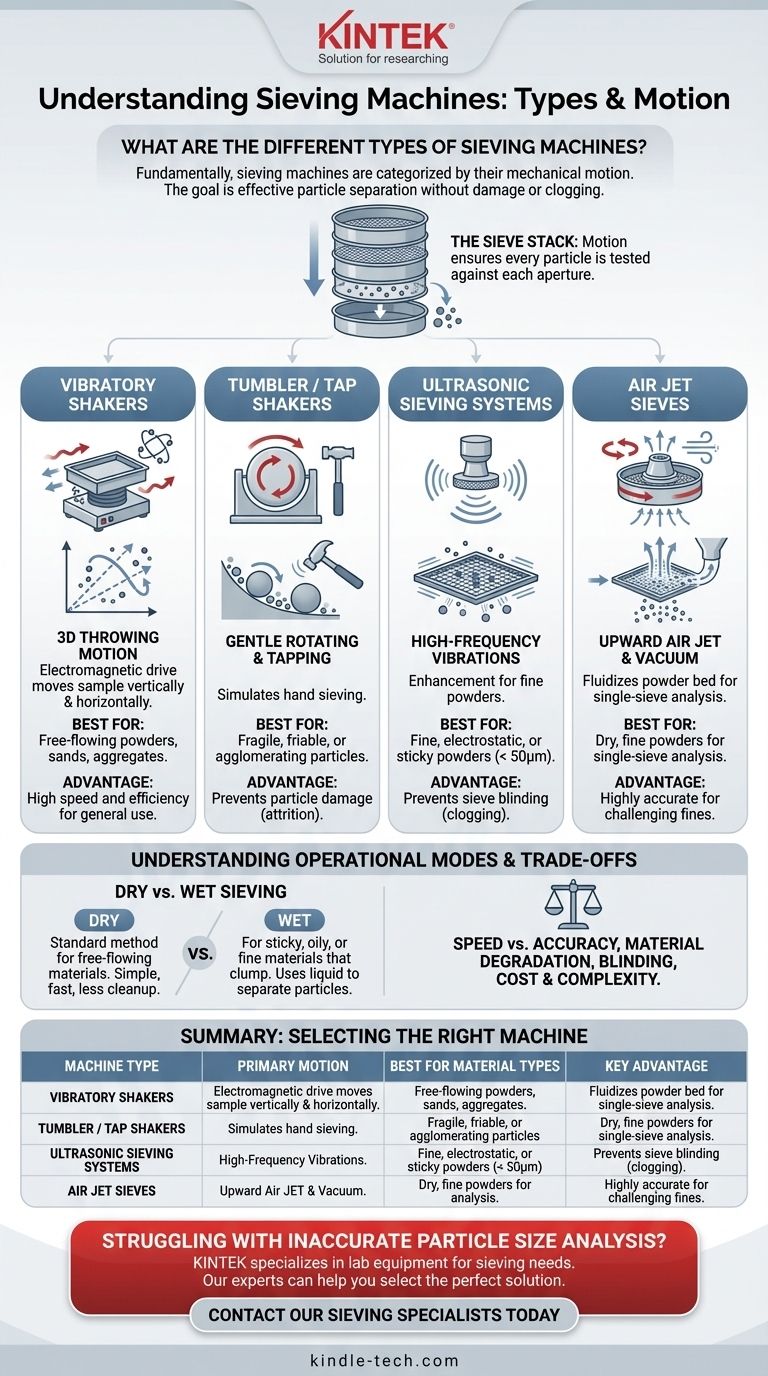

Fundamentally, sieving machines are categorized by the type of mechanical motion they use to separate particles. The most common types are vibratory shakers, which use a three-dimensional throwing motion, and tumbler or tap shakers, which use a gentler rotating and tapping action. More specialized systems use ultrasonics or air jets for very fine or difficult-to-sieve materials.

The choice of a sieving machine is not about which is "best," but which motion is most effective for your specific material's properties and analysis goals. The core challenge is ensuring every particle has a chance to pass through a sieve aperture without damaging the particle or clogging the mesh.

The Core Principle: Motion and Separation

Every sieving machine is designed to solve a simple problem: how to move a stack of test sieves in a way that gives particles the maximum opportunity to be tested against each sieve opening. The method of agitation is the primary differentiator.

The Sieve Stack

All analytical sieving is performed with a sieve stack, which is a column of test sieves with progressively finer mesh sizes from top to bottom. A pan at the bottom collects the finest particles.

The Role of Mechanical Motion

The machine's job is to impart energy to the material on each sieve. This motion lifts the particles, rotates them, and reorients them, preventing the sieve from becoming clogged and ensuring an accurate separation based on size.

Primary Types of Sieving Machines by Motion

The method of agitation directly impacts efficiency, analysis time, and suitability for different material types.

Vibratory Sieve Shakers (The Workhorse)

This is the most common type of sieving machine. It uses an electromagnetic drive to create a 3D throwing motion, which moves the sample both vertically and horizontally.

This combined motion spreads the material evenly across the sieve surface and continuously reorients the particles, making it highly efficient for a wide range of free-flowing powders, sands, and aggregates.

Tumbler (or Tap) Sieve Shakers (The Gentle Giant)

These machines simulate the motion of hand sieving. They use a horizontal, circular motion combined with a periodic vertical tapping action.

This gentler motion is ideal for materials that are fragile, prone to breaking, or tend to agglomerate. The tapping helps break up light clumps and de-blind the sieve mesh without destroying the primary particles.

Ultrasonic Sieving Systems (The Specialist)

This is not a standalone machine but an enhancement, typically for vibratory shakers. A transducer transmits high-frequency ultrasonic vibrations directly to the sieve mesh.

These micro-vibrations are exceptionally effective at preventing blinding (clogging) of the sieve mesh when working with very fine, electrostatically charged, or slightly sticky powders, often below 50 microns.

Air Jet Sieves (The Fine Powder Expert)

An air jet sieving machine is designed for single-sieve analysis of fine, dry powders. It uses a rotating nozzle below the sieve mesh to blow a jet of air upwards.

This air jet fluidizes the powder bed, lifting the fine particles and carrying them through the mesh, while a vacuum pulls them away. This is extremely effective for powders that would otherwise blind a standard sieve stack.

Understanding Key Operational Modes

Beyond the machine's motion, the process can be run dry or wet, depending entirely on the material's characteristics.

Dry Sieving: The Standard Method

Dry sieving is the default method for most materials that are free-flowing and do not clump together. It is simpler, faster, and requires less cleanup.

Wet Sieving: For Difficult Materials

Wet sieving is necessary for materials that agglomerate, are oily, or contain very fine particles that stick together due to static or moisture. A liquid (usually water) is used to wash the material through the sieve stack. This breaks surface tension and separates individual particles for an accurate analysis.

Understanding the Trade-offs

Selecting a machine involves balancing speed, accuracy, and compatibility with your specific material.

Speed vs. Accuracy

Vibratory shakers are generally the fastest for standard materials. However, for fine powders that blind the mesh, an ultrasonic or air jet system will ultimately be more accurate and repeatable, even if the setup is more involved.

Material Degradation

An aggressive vibratory motion can break down friable or needle-shaped particles, a phenomenon known as attrition. This skews results by creating more fines than were originally present. A gentler tumbler shaker is the correct choice to prevent this.

The Problem of "Blinding"

Blinding occurs when particles become lodged in the sieve apertures, blocking them. This is the single biggest source of inaccurate results. Ultrasonic systems and wet sieving are the most direct solutions to this problem.

Cost and Complexity

Standard vibratory shakers are robust, versatile, and cost-effective. Specialized systems like air jet and ultrasonic sieves represent a higher investment and are typically reserved for specific, challenging applications where standard methods fail.

Making the Right Choice for Your Goal

Your material dictates the method. Use these guidelines to determine the best starting point for your application.

- If your primary focus is general-purpose analysis of free-flowing granules or powders: A vibratory sieve shaker is the industry standard and most efficient choice.

- If your primary focus is preventing particle damage or separating light agglomerates: A tumbler or tap shaker provides a gentler action that preserves particle integrity.

- If your primary focus is analyzing very fine powders (< 50 microns) prone to blinding: An ultrasonic system or an air jet sieve is required for accurate and repeatable results.

- If your primary focus is separating materials that are sticky, oily, or heavily clumped: Wet sieving is the only reliable method to ensure complete particle separation.

Choosing the right sieving technology is the first and most critical step toward reliable particle size analysis.

Summary Table:

| Machine Type | Primary Motion | Best For Material Types | Key Advantage |

|---|---|---|---|

| Vibratory Shaker | 3D Throwing Motion | Free-flowing powders, sands, aggregates | High speed and efficiency for general use |

| Tumbler/Tap Shaker | Gentle Rotating & Tapping | Fragile, friable, or agglomerating particles | Prevents particle damage (attrition) |

| Ultrasonic System | High-Frequency Vibrations | Fine, electrostatic, or sticky powders (< 50µm) | Prevents sieve blinding (clogging) |

| Air Jet Sieve | Upward Air Jet & Vacuum | Dry, fine powders for single-sieve analysis | Highly accurate for challenging fines |

Struggling with inaccurate particle size analysis due to sieve blinding or particle damage? The right sieving machine is critical for repeatable results. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the perfect vibratory, tumbler, ultrasonic, or air jet sieve shaker for your specific material—ensuring efficiency, accuracy, and particle integrity. Contact our sieving specialists today to optimize your particle analysis workflow!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency