The primary drawbacks of a ball mill are its high energy consumption, significant noise and vibration, and the potential for product contamination from the wearing of grinding media and liners. This method is also a relatively slow process and is ineffective for processing materials that are soft, tacky, or fibrous.

While a ball mill is a robust and simple tool for achieving very fine particle sizes, its drawbacks stem from this very simplicity. It is an energy-intensive and often slow process with inherent risks of contamination and limitations on the types of materials it can effectively process.

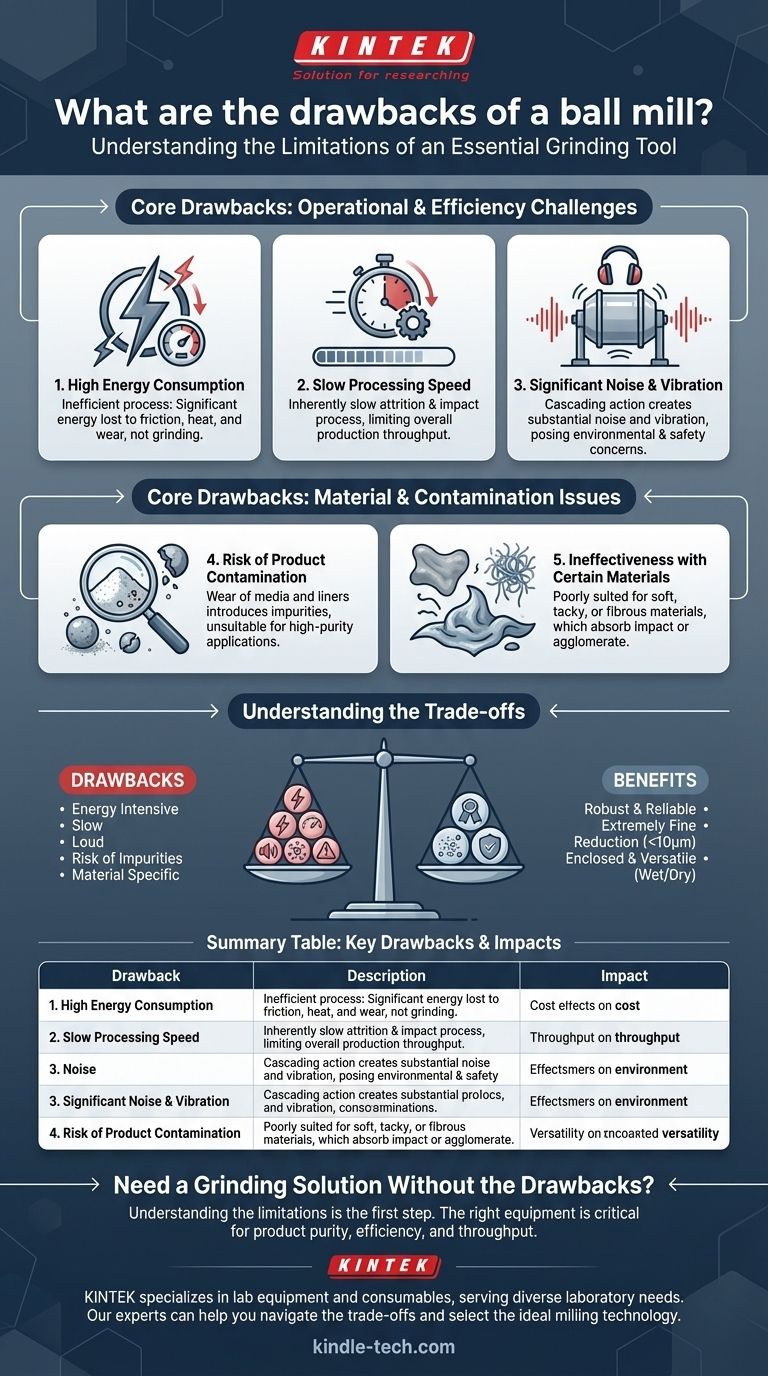

Operational and Efficiency Challenges

The day-to-day operation of a ball mill presents several practical disadvantages that impact cost, environment, and throughput.

High Energy Consumption

A significant portion of the energy supplied to a ball mill is not used for grinding. Instead, it is lost to friction between the balls and liners, heat generation in the material, and the mechanical wearing of components. This makes the process inefficient from an energy standpoint.

Slow Processing Speed

Ball milling is a method of attrition and impact that takes considerable time. Compared to other grinding technologies, it is a slow process, which can limit the overall throughput of a production line.

Significant Noise and Vibration

The cascading and tumbling action of steel or ceramic balls inside a large metal drum produces substantial noise and vibration. While using rubber balls or liners can mitigate this, it remains a considerable environmental and safety concern in any facility.

Material and Contamination Issues

The interaction between the grinding media and the material being processed creates fundamental limitations, particularly concerning product purity and material compatibility.

Risk of Product Contamination

The constant impact and friction cause the grinding media (balls) and the internal cylinder lining to wear down over time. This wear introduces fine particles of the media—often steel or ceramic—into the product, which is a critical issue for high-purity applications.

Ineffectiveness with Certain Materials

Ball mills work by fracturing brittle materials. They are poorly suited for materials that are soft, tacky, or fibrous. These materials tend to absorb the impact, deform, or agglomerate rather than breaking down into a fine powder.

Large Footprint and Weight

Ball mills are inherently heavy and bulky machines. Their large weight and the significant space required for installation can be a major constraint, especially in facilities with limited floor space.

Understanding the Trade-offs

To make an informed decision, it's crucial to weigh these drawbacks against the significant benefits that have made ball mills a staple in many industries.

The Benefit: Simplicity and Reliability

Ball mills are mechanically simple and exceptionally robust. Their design ensures reliability, operational safety, and straightforward servicing, making them a durable workhorse for many applications.

The Benefit: Extremely Fine Particle Reduction

Despite being slow, a ball mill's primary strength is its ability to produce a very fine and consistent powder, often with particle sizes of 10 microns or less. It maintains this milling fineness over long periods with minimal adjustment.

The Benefit: Versatility and Containment

The enclosed cylinder makes ball mills ideal for grinding toxic materials safely or for maintaining sterile conditions in pharmaceutical manufacturing. They are also highly versatile, suitable for both wet and dry grinding processes and capable of handling very abrasive materials effectively.

Making the Right Choice for Your Process

Your specific goal will determine whether a ball mill's disadvantages are acceptable trade-offs for its benefits.

- If your primary focus is absolute product purity: Be aware of contamination from media and liner wear and consider alternative milling methods or specialized ceramic components.

- If your primary focus is energy efficiency and low operational cost: The high specific energy consumption of a ball mill will be a significant factor in your total cost of ownership.

- If your primary focus is high-speed throughput: Recognize that ball milling is an inherently slow process and may create a bottleneck in your production.

- If your primary focus is processing soft or fibrous materials: A ball mill is unsuitable for this purpose and will not perform effectively.

Understanding these inherent limitations is the first step toward selecting the right grinding technology for your specific material and production goals.

Summary Table:

| Drawback | Description | Impact |

|---|---|---|

| High Energy Consumption | Significant energy is lost to friction and heat, not grinding. | Increases operational costs. |

| Risk of Contamination | Wear of grinding media and liners can introduce impurities. | Unsuitable for high-purity applications. |

| Slow Processing Speed | An inherently slow attrition and impact process. | Limits production throughput. |

| Noise and Vibration | Tumbling action of balls creates substantial noise. | Environmental and safety concern. |

| Material Limitations | Ineffective for soft, tacky, or fibrous materials. | Reduces application versatility. |

Need a Grinding Solution Without the Drawbacks?

Understanding the limitations of a ball mill is the first step to optimizing your process. The right equipment is critical for achieving your goals in product purity, efficiency, and throughput.

KINTEK specializes in lab equipment and consumables, serving diverse laboratory needs. Our experts can help you navigate the trade-offs and select the ideal milling technology for your specific materials and production requirements.

Contact our team today to discuss your application and discover a grinding solution that enhances your lab's performance and cost-efficiency.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- Why is the pelletizing, crushing, and sieving of biomass raw materials necessary? Ensure Gasification Stability

- In which industry is a ball mill used? From Mining to Nanotech, Unlock Versatile Grinding

- What is the primary function of a ball mill in calcium thermal reduction? Optimize Your Raw Material Preparation

- What is the primary function of a laboratory ball mill in Rice Husk Ash (RHA) modification? Achieve Peak Densification

- Why is an agate mortar and pestle preferred for grinding MAX phase? Ensure Sample Purity & Zero Contamination

- How many types of ball mills are there? Choose the Right Mill for Your Lab or Industry

- What is the function of ultrasonic homogenizers in g-C3N4 preparation? Unlocking Maximum Catalytic Activity

- What are the safety precautions when using a grinder? Protect Yourself from High-Speed Hazards