In essence, ball milling is a high-energy mechanical process that uses repeated impacts to induce profound structural and chemical changes in a material. Its primary and most well-known effect is particle size reduction, but its capabilities extend far beyond simple grinding, enabling the creation of new alloys, amorphous materials, and novel chemical compounds.

Ball milling should not be viewed merely as a grinding technique. It is a powerful solid-state processing tool where intense mechanical energy is used to fundamentally alter a material's physical structure and chemical properties without melting.

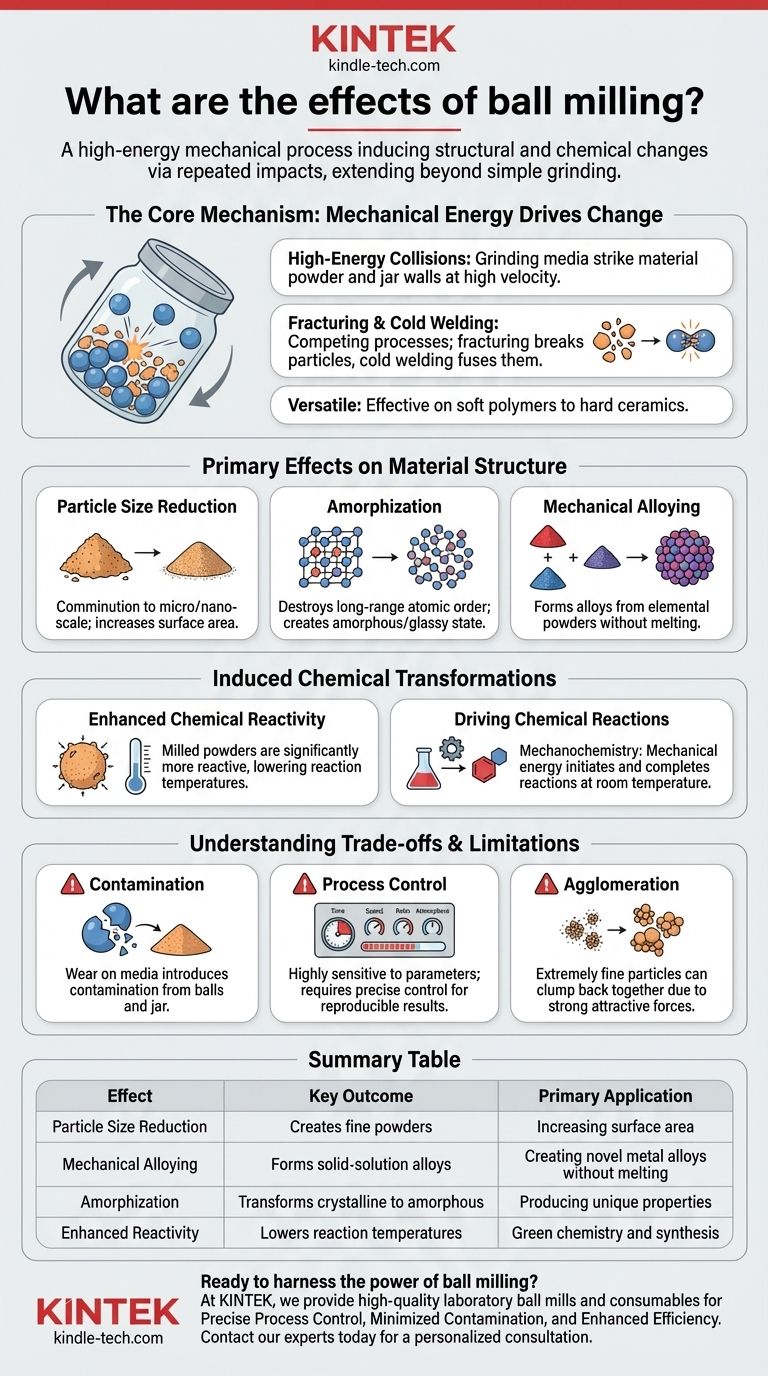

The Core Mechanism: How Mechanical Energy Drives Change

Ball milling harnesses the kinetic energy of grinding media (balls) colliding with a material powder inside a rotating or vibrating container (jar). These repeated, high-energy collisions are the source of all subsequent effects.

High-Energy Collisions

The process involves placing a material, often in powder form, into a jar with hardened balls (e.g., steel, tungsten carbide, or zirconia). The jar is then subjected to high-speed rotation or agitation, causing the balls to cascade and repeatedly strike the material powder and the jar walls at high velocity.

Fracturing and Cold Welding

Two competing processes occur at the microscopic level during these impacts. Fracturing breaks particles apart, reducing their size. Simultaneously, the immense pressure at the point of impact can cause particles to fuse together in a process called cold welding. The balance between these two actions dictates the final state of the material.

A Versatile Process

A key strength of this technique is its applicability to a vast range of materials. As the energy transfer is purely mechanical, it is effective on everything from soft polymers to extremely hard ceramics, including brittle and fibrous substances.

Primary Effects on Material Structure

The intense mechanical energy imparted during milling leads to significant and often desirable changes in the physical structure of the material.

Particle Size Reduction (Comminution)

This is the most fundamental effect. Ball milling can efficiently reduce the particle size of a coarse powder down to the micrometer or even nanometer scale. This drastic increase in surface area is critical for many applications.

Amorphization

The severe plastic deformation caused by the repeated impacts can destroy a material's long-range atomic order. This can transform a crystalline material into an amorphous or "glassy" state, which possesses unique properties different from its crystalline counterpart.

Mechanical Alloying

Ball milling is a primary method for producing alloys from elemental powders without melting. By milling two or more different metal powders together, the repeated fracturing and cold welding events mix the elements at an atomic level, forming a true solid-solution alloy.

Induced Chemical Transformations

The mechanical energy of ball milling is potent enough to directly influence and even drive chemical reactions, a field known as mechanochemistry.

Enhanced Chemical Reactivity

The combination of extremely small particle size, high surface area, and an increase in crystal defects makes milled powders significantly more reactive than their bulk counterparts. This can lower the temperature required for subsequent chemical reactions.

Driving Chemical Reactions

In some cases, the mechanical energy alone is sufficient to initiate and complete a chemical reaction. This allows for the synthesis of compounds at room temperature that would otherwise require high heat, making it a valuable tool in "green chemistry."

Understanding the Trade-offs and Limitations

While powerful, ball milling is not without its challenges. Understanding these is critical for achieving reliable and meaningful results.

Contamination

The constant, high-energy impact causes wear on the grinding media (the balls and the jar). This inevitably introduces contamination from the media material into your sample, which can be a significant issue for high-purity applications.

Process Control

The final outcome is highly sensitive to a range of parameters. Variables such as milling time, speed, ball-to-powder weight ratio, and the atmosphere inside the jar must be precisely controlled to ensure reproducible results.

Agglomeration

As particles become extremely fine (nanoscale), the strong attractive forces between them can cause them to clump back together, or agglomerate. This can counteract the goal of size reduction and requires careful management of the process or the use of process control agents.

Making the Right Choice for Your Goal

To effectively leverage ball milling, you must align the process parameters with your specific objective.

- If your primary focus is particle size reduction: Prioritize choosing grinding media that minimizes contamination and optimize milling time to avoid excessive agglomeration.

- If your primary focus is creating novel alloys: Mechanical alloying is a core strength. It is critical to control the atmosphere inside the jar (e.g., using an inert gas like argon) to prevent oxidation of the metal powders.

- If your primary focus is inducing chemical reactions: View the mill as a chemical reactor. The mechanical energy provides the activation needed to drive reactions at or near room temperature.

- If your primary focus is altering material structure (e.g., amorphization): This typically requires high-energy input and extended milling times to sufficiently break down the crystalline lattice.

Ultimately, ball milling provides a powerful and versatile method for manipulating materials at a fundamental level through controlled mechanical force.

Summary Table:

| Effect | Key Outcome | Primary Application |

|---|---|---|

| Particle Size Reduction | Creates fine powders (micro/nano-scale) | Increasing surface area for reactions |

| Mechanical Alloying | Forms solid-solution alloys from elemental powders | Creating novel metal alloys without melting |

| Amorphization | Transforms crystalline materials into amorphous states | Producing materials with unique properties |

| Enhanced Reactivity | Lowers reaction temperatures and drives mechanochemistry | Green chemistry and material synthesis |

Ready to harness the power of ball milling in your lab?

At KINTEK, we specialize in providing high-quality laboratory ball mills and consumables tailored to your specific research needs. Whether your goal is mechanical alloying, particle size reduction, or driving chemical reactions, our equipment ensures precise control and reproducible results.

We help you achieve:

- Precise Process Control: Optimize parameters like speed, time, and atmosphere for your target outcome.

- Minimized Contamination: Choose from a variety of grinding media materials to protect your sample's purity.

- Enhanced Efficiency: Accelerate your materials development and chemical synthesis workflows.

Let's discuss how our solutions can advance your projects. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the function of a planetary ball mill for B4C–W powders? Optimize Homogeneity & Sintering Quality

- What is the effect of ball size in ball milling? Optimize Particle Size and Reaction Efficiency

- Why are tungsten carbide grinding jars and balls preferred? Ensure Purity in Long-Duration Mechanical Alloying

- What factors influence the size of the product in the ball mill? Master Grinding Media, Speed, and Feed for Precision

- Why is it necessary to control temperature and use high-purity argon gas when mixing FeCrAlY in a ball mill?

- What role do stainless steel ball milling jars play in Si-C anode synthesis? Optimize Your High-Energy Milling Energy Transfer

- How do you increase production in a ball mill? Optimize Speed, Media, and Feed for Maximum Throughput

- What is the specific role of a planetary ball mill in the preparation of Ag-SnO2-Y2O3 composite powders?