In a bead mill, grindability is primarily controlled by four interconnected factors: the size of the grinding beads, the speed of the rotor, the type of rotor used, and the total mass of the beads charged into the mill. These variables collectively determine the energy and frequency of the grinding events, which directly dictate the final particle size and the overall speed of the process.

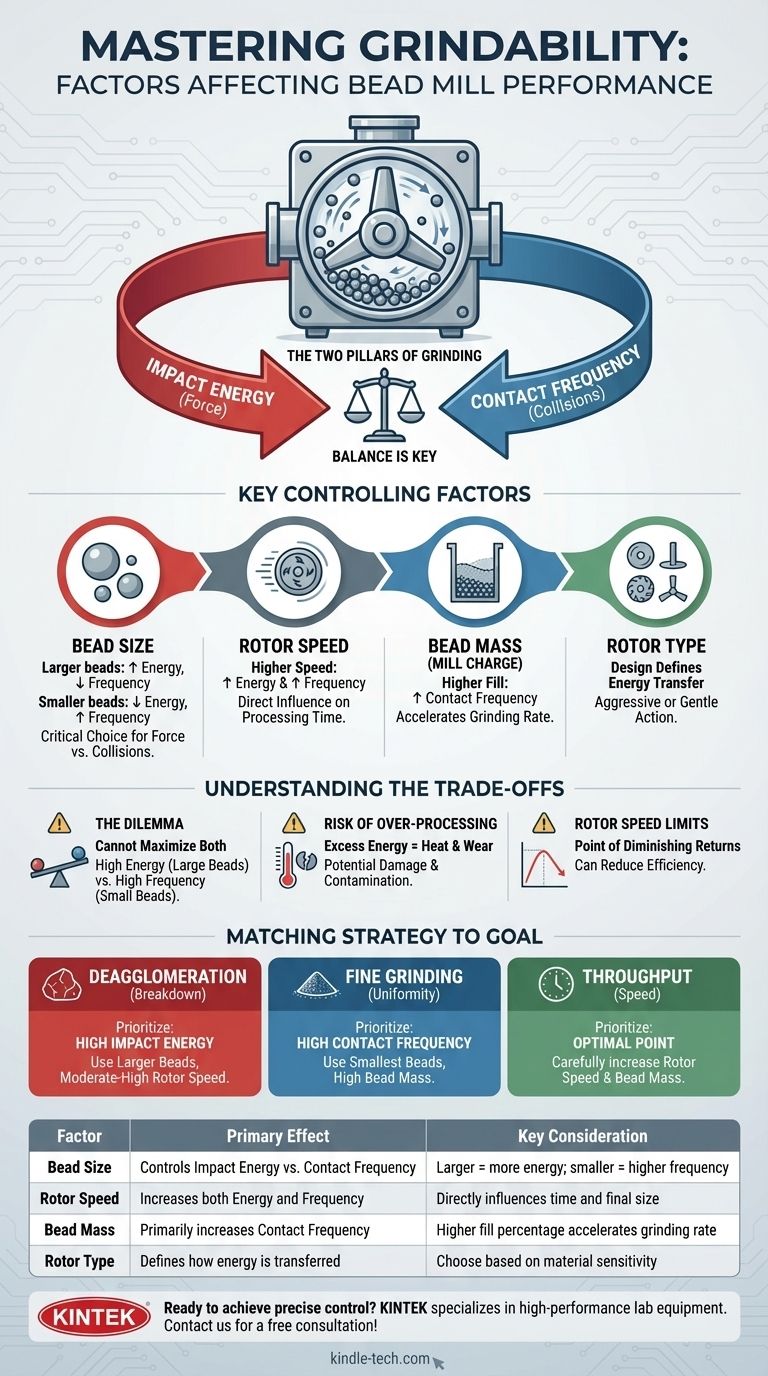

The core principle of grindability is a balance between two competing forces: impact energy (the force of each individual collision) and contact frequency (the total number of collisions). Mastering your grinding process requires you to manipulate the key factors to achieve the right balance for your specific material and target outcome.

The Two Pillars of Grinding: Energy and Frequency

To effectively control a grinding process, you must understand how you are applying force to your material. This is achieved through two distinct but related mechanisms.

Impact Energy: The Force of Each Collision

Impact energy is the amount of kinetic force transferred during a single collision between a grinding bead and a material particle.

High impact energy is essential for fracturing larger, harder particles or breaking up tough agglomerates.

Contact Frequency: The Number of Collisions

Contact frequency refers to the total number of grinding events (collisions) that occur within the mill over a period of time.

High contact frequency is critical for efficiently reducing particles to a very fine, uniform size and for increasing the overall processing rate.

Key Factors Controlling Grindability

Each parameter of your bead mill setup is a lever you can pull to adjust the balance between impact energy and contact frequency.

Bead Size

The size of your grinding media is one of the most critical choices.

Larger beads carry more momentum and therefore create higher impact energy. However, fewer large beads can fit into the mill chamber, resulting in a lower contact frequency.

Conversely, smaller beads deliver much lower impact energy but allow for a vastly higher number of beads in the mill, dramatically increasing contact frequency.

Rotor Speed

Rotor speed (often measured as agitator tip speed) is a primary control for adding energy to the system.

Increasing rotor speed increases both the impact energy of each collision and the overall contact frequency. It is the most direct way to influence processing time.

Bead Mass (Mill Charge)

This refers to the total mass of beads loaded into the mill, often expressed as a percentage of the chamber volume (e.g., 80% fill).

A higher bead mass means more beads are in the chamber. This significantly increases contact frequency, which accelerates the grinding process.

Rotor Type

The physical design of the rotor (e.g., discs, pins, or paddles) fundamentally changes how energy is transferred to the bead slurry.

Some rotor designs are more aggressive, creating zones of very high energy for intense grinding. Others are designed for more gentle, uniform circulation, which can be better for sensitive materials.

Understanding the Trade-offs

Optimizing grindability is not about maximizing every variable. It's about making deliberate choices and understanding the consequences.

The Energy vs. Frequency Dilemma

You cannot simultaneously maximize impact energy and contact frequency.

High-energy setups (large beads) are inefficient for fine grinding because the number of contact points is too low. High-frequency setups (small beads) may lack the force needed to break down the initial feed material.

The Risk of Over-Processing

Simply running the mill at maximum speed for a long time can be counterproductive.

Excessive energy input can generate heat, potentially damaging the product. It also accelerates the wear of your beads and mill components, which can introduce contamination.

Rotor Speed Isn't a Silver Bullet

While increasing rotor speed is effective, there is a point of diminishing returns.

Beyond an optimal speed, the additional energy input can cause the bead mass to "pack" against the mill wall or introduce process instability, reducing grinding efficiency rather than increasing it.

Matching Your Strategy to Your Goal

Your ideal setup depends entirely on your objective. Use these principles to guide your decisions.

- If your primary focus is breaking down large, hard particles (Deagglomeration): Prioritize high impact energy by using larger grinding beads and a moderate-to-high rotor speed.

- If your primary focus is achieving a very fine, uniform particle size (Fine Grinding): Prioritize high contact frequency by using the smallest beads capable of the task and a high bead mass.

- If your primary focus is maximizing processing speed (Throughput): Carefully increase rotor speed and bead mass to find the optimal point that accelerates the process without generating excessive heat or wear.

By understanding these fundamental factors, you gain precise control over your grinding process and its final outcome.

Summary Table:

| Factor | Primary Effect on Grinding | Key Consideration |

|---|---|---|

| Bead Size | Controls Impact Energy vs. Contact Frequency | Larger beads = more energy; smaller beads = higher frequency |

| Rotor Speed | Increases both Energy and Frequency | Directly influences processing time and final particle size |

| Bead Mass (Mill Charge) | Primarily increases Contact Frequency | Higher fill percentage accelerates the grinding rate |

| Rotor Type | Defines how energy is transferred | Choose based on material sensitivity and required grinding intensity |

Ready to achieve precise control over your particle size and grinding efficiency?

KINTEK specializes in high-performance lab equipment and consumables, including bead mills and grinding media. Our experts can help you select the ideal setup—balancing bead size, rotor speed, and other critical factors—to perfectly match your material and target outcome.

Contact us today to discuss your specific application and discover how our solutions can enhance your lab's productivity and results.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- Laboratory Ten-Body Horizontal Jar Mill for Lab Use

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- Why is grinding and sieving equipment used for waste tire hydrothermal liquefaction? Maximize Your Reaction Efficiency

- What types of contamination and changes in composition can occur during crushing and grinding? Protect Your Sample Integrity

- What is the primary function of a laboratory ball mill in msHAP post-processing? Achieve Precise Particle Refinement

- What is the function of a 3D motion mixer with WC balls for high-entropy alloys? Ensure Perfect Powder Homogeneity

- What is the maximum speed of a ball mill? Find the Optimal Speed for Efficient Grinding

- What are the two primary types of jet mills and how are they differentiated? Compare FBJM vs. Spiral Jet Mills

- What are the advantages of using high-purity Silicon Carbide (SiC) grinding media? Ensure Purity & Refinement

- What is the function of a Wiley grinding mill in the processing of elephant grass? Optimize Your Chemical Analysis