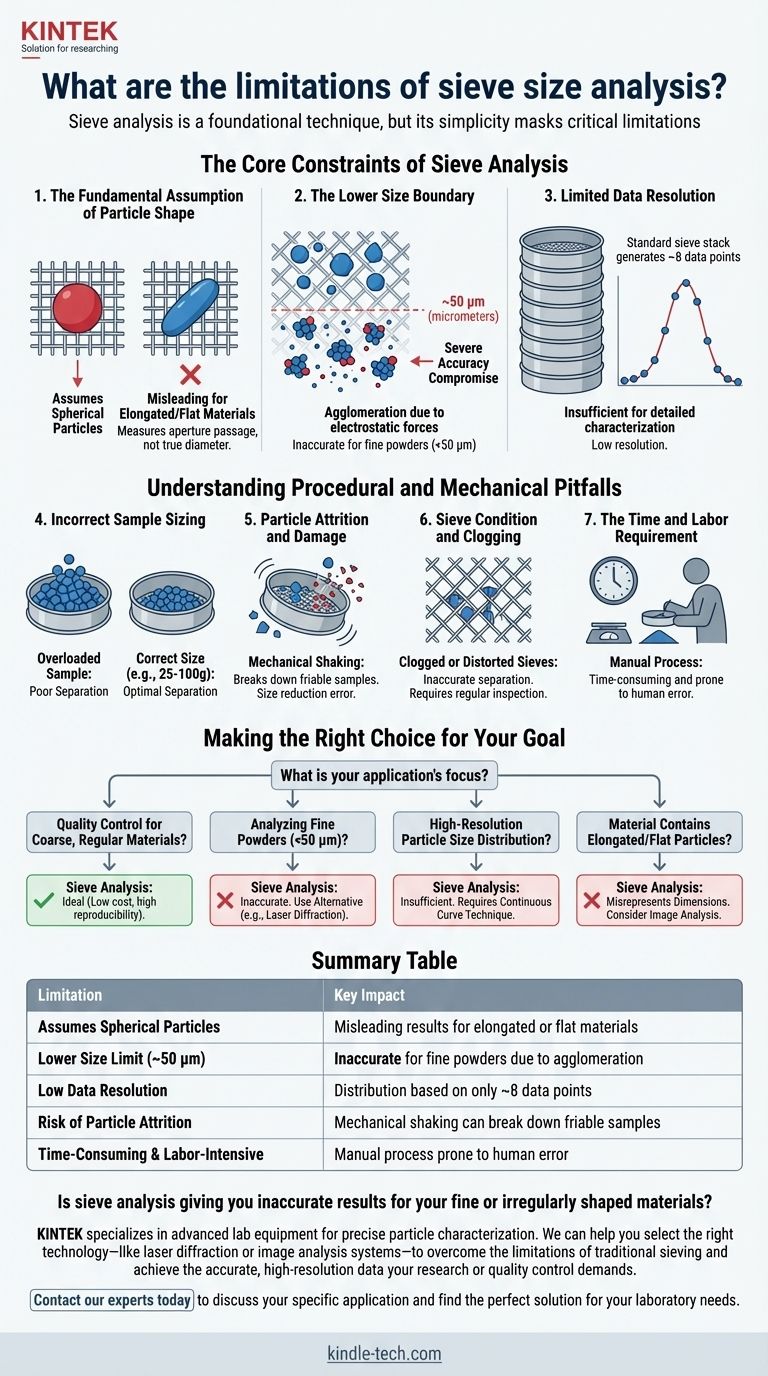

Sieve analysis is a foundational technique in particle characterization, but its apparent simplicity masks critical limitations. The method is fundamentally constrained by particle shape, size, and the low resolution of its results. It is unreliable for particles smaller than 50 µm, assumes all particles are perfect spheres, and typically generates a size distribution based on fewer than a dozen data points.

While cost-effective and straightforward for coarse, spherical particles, the reliability of sieve analysis breaks down for fine, elongated, or irregularly shaped materials. Understanding these boundaries is the key to achieving accurate and meaningful results.

The Core Constraints of Sieve Analysis

Sieve analysis works by mechanically passing particles through a series of screens with progressively smaller mesh sizes. This physical separation method introduces several inherent constraints that are crucial to understand.

The Fundamental Assumption of Particle Shape

Sieve analysis does not measure a particle's true diameter. It measures whether a particle can pass through a square aperture.

This process inherently assumes particles are spherical. For elongated or flat particles, the results can be misleading. A long, thin particle may pass end-on through a sieve opening much smaller than its actual length, causing it to be categorized as a much smaller particle.

This leads to unreliable mass-based results for non-spherical materials, as the final fraction weights do not accurately represent the true particle dimensions.

The Lower Size Boundary

The effectiveness of sieve analysis significantly decreases for fine powders.

The practical lower limit for this technique is approximately 50 micrometers (µm). Below this threshold, and often for materials finer than 100 mesh, accuracy is severely compromised.

Fine particles tend to agglomerate due to electrostatic forces, preventing them from passing through the sieve mesh correctly. This results in an inaccurate over-representation of coarse particles.

Limited Data Resolution

The detail of the particle size distribution curve is another significant limitation.

A standard sieve stack typically consists of a maximum of eight sieves. This means the entire size distribution is defined by just eight data points.

This low resolution is often insufficient for detailed process control or research applications where a continuous and more granular understanding of the particle size distribution is required.

Understanding Procedural and Mechanical Pitfalls

Beyond its theoretical constraints, the accuracy of sieve analysis is highly dependent on proper procedure and equipment maintenance. Errors in these areas can easily invalidate results.

Incorrect Sample Sizing

Using a sample that is too large is a common source of error. An overloaded sieve prevents individual particles from having the opportunity to present themselves to the mesh openings.

A sample size between 25 and 100 grams is generally recommended. The optimal size must be determined for each specific material to ensure accuracy.

Particle Attrition and Damage

The mechanical shaking action can be destructive to the material being tested.

Friable or delicate particles can break down during the agitation process. This size reduction error, or attrition, skews the results toward a finer distribution than what was present in the original sample.

Sieve Condition and Clogging

The physical condition of the sieves is paramount. Over time, sieves can become clogged with particles, or the wire mesh can become distorted or damaged.

Clogged or distorted sieves will not provide an accurate separation, leading to significant and often unnoticed errors in the final analysis. Regular inspection and cleaning are essential.

The Time and Labor Requirement

While conceptually simple, sieve analysis can be a time-consuming and labor-intensive process when performed correctly.

The procedure requires careful sample preparation, pre-weighing of all empty sieves, a potentially long sieving time, and meticulous back-weighing of each fraction. This manual process introduces multiple steps where human error can occur.

Making the Right Choice for Your Goal

The value of sieve analysis depends entirely on whether its limitations impact your specific application. Use these guidelines to determine if it is the appropriate method for your needs.

- If your primary focus is quality control for coarse, regular materials: Sieve analysis is often an ideal choice due to its low cost, ease of use, and high reproducibility for suitable samples.

- If you are analyzing fine powders or materials below 50 µm: You must use an alternative method, such as laser diffraction, to achieve accurate and reliable results.

- If you need a high-resolution particle size distribution: Sieve analysis will be insufficient, and a technique that generates a continuous curve is necessary for detailed characterization.

- If your material contains elongated or flat particles: Be aware that sieve analysis will misrepresent the true particle dimensions, and you should consider image analysis to understand the material's morphology.

By understanding these inherent limitations, you can confidently determine when to rely on sieve analysis and when to seek a more advanced characterization technique.

Summary Table:

| Limitation | Key Impact |

|---|---|

| Assumes Spherical Particles | Misleading results for elongated or flat materials |

| Lower Size Limit (~50 µm) | Inaccurate for fine powders due to agglomeration |

| Low Data Resolution | Distribution based on only ~8 data points |

| Risk of Particle Attrition | Mechanical shaking can break down friable samples |

| Time-Consuming & Labor-Intensive | Manual process prone to human error |

Is sieve analysis giving you inaccurate results for your fine or irregularly shaped materials?

KINTEK specializes in advanced lab equipment for precise particle characterization. We can help you select the right technology—like laser diffraction or image analysis systems—to overcome the limitations of traditional sieving and achieve the accurate, high-resolution data your research or quality control demands.

Contact our experts today to discuss your specific application and find the perfect solution for your laboratory needs.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability

- What is the function of sieving equipment in CuAlMn alloys? Master Pore Size Precision

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation