The primary parameters of the ball mill process are the rotational speed of the cylinder, the characteristics of the grinding media (size, material, and quantity), and the properties of the material being ground. These factors are not independent; they work together within the physical confines of the mill to determine the efficiency and final particle size of the product.

The goal of managing ball mill parameters is to create the optimal environment for controlled collisions. It's not about maximizing speed or force, but about precisely balancing the forces of impact and attrition to achieve the desired particle size reduction efficiently.

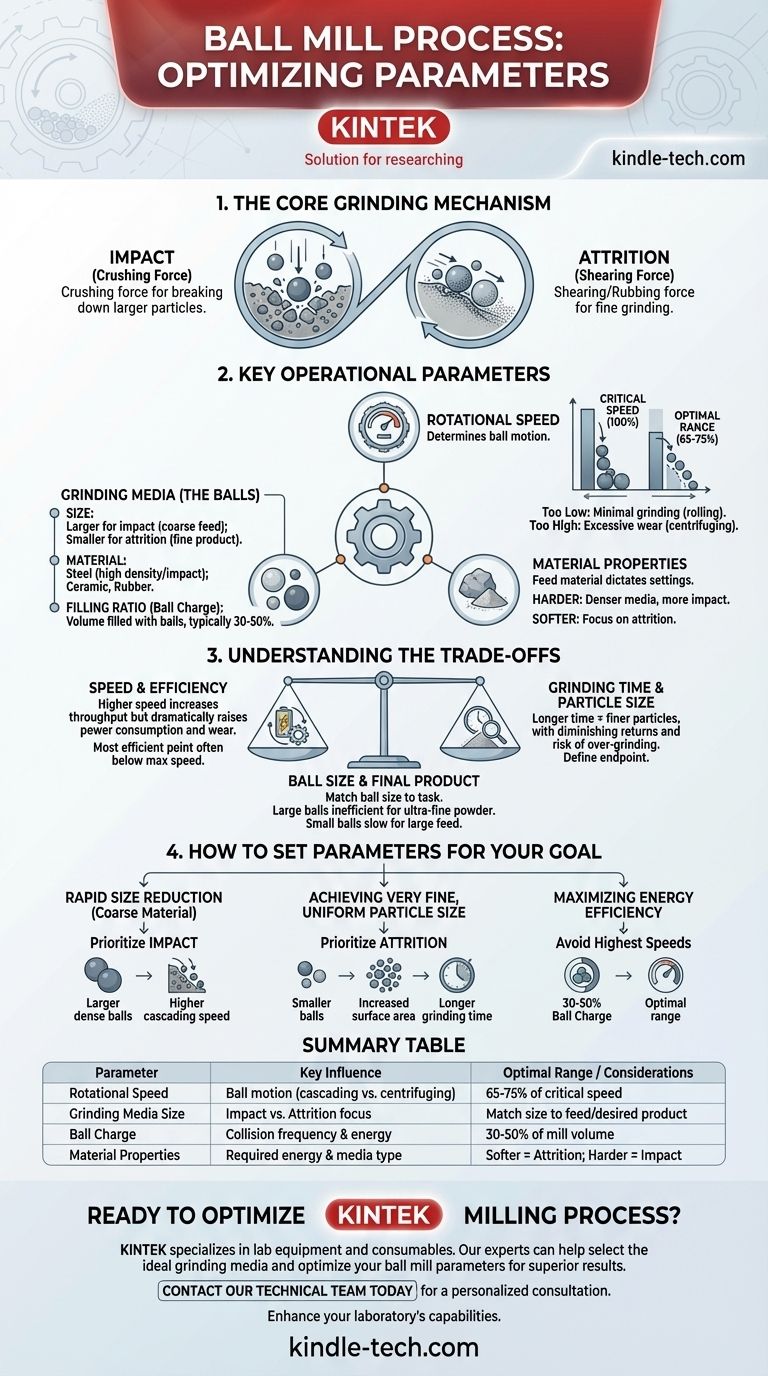

The Core Grinding Mechanism

A ball mill reduces material size through two primary physical forces. Your control over the operational parameters is fundamentally about manipulating the balance between these two actions.

Understanding Impact

Impact is the crushing force that occurs when the grinding media (the balls) are lifted by the rotating shell and fall onto the material below. This action is most effective for breaking down larger, coarser particles.

Understanding Attrition

Attrition is the shearing and rubbing force that occurs as balls and material particles slide and roll against each other. This action is responsible for grinding particles down to a much finer size.

Key Operational Parameters and Their Influence

Each parameter serves as a lever to adjust the grinding process. Understanding how each one affects the internal dynamics of the mill is critical for process control.

Rotational Speed

This is arguably the most critical parameter. The speed determines how the balls move inside the mill.

The concept of critical speed is the rotational velocity at which centrifugal force causes the balls to cling to the inner wall of the shell, ceasing any grinding action. Effective operation occurs at a percentage of this speed, typically 65-75%.

If the speed is too low, the balls simply roll at the bottom of the mill, leading to minimal grinding. If the speed is too high (approaching critical speed), the balls are thrown against the liner, causing excessive wear and reducing the crucial cascading and falling action needed for impact.

Grinding Media (The Balls)

The balls are the primary tool for size reduction. Their characteristics directly influence the type of grinding that occurs.

- Size: Larger balls create more powerful impacts, ideal for breaking down coarse feed material. Smaller balls provide a greater surface area and more contact points, favoring attrition and producing a finer final product.

- Material: Balls are typically made from steel, ceramic, or rubber. Denser materials like steel deliver higher impact energy.

- Filling Ratio (Ball Charge): The volume of the mill filled with balls, typically between 30% and 50%. Too low a charge results in fewer collisions and inefficient grinding. Too high a charge restricts the movement of the media, dampening their impact force.

Material Properties

The characteristics of the material you are grinding (the "feed") dictate the ideal settings for all other parameters. Harder materials may require denser media and more impact force, while softer materials might grind more efficiently with a focus on attrition.

Understanding the Trade-offs

Optimizing a ball mill is a process of balancing competing factors. There is rarely a single "best" setting, only the best setting for a specific goal.

Speed vs. Efficiency

Running the mill at a higher speed increases throughput to a point, but it also dramatically increases power consumption and wear on the mill liner and grinding media. The most energy-efficient point is often well below the maximum possible operating speed.

Grinding Time vs. Particle Size

Longer grinding times will produce finer particles, but with diminishing returns. Over-grinding can waste significant energy and, in some cases, can even alter the chemical properties of the material. Defining a clear endpoint is crucial for an efficient process.

Ball Size vs. Final Product

You must match the ball size to the task. Using large balls to achieve an ultra-fine powder is highly inefficient, as they are poor at the attrition needed for fine grinding. Conversely, using small balls to break down large feed material will be an extremely slow process.

How to Set Parameters for Your Goal

Your optimal settings depend entirely on your desired outcome. Use these principles as a starting point for process optimization.

- If your primary focus is rapid size reduction of coarse material: Prioritize impact forces by using larger, denser grinding media and operating at a speed that maximizes the cascading motion of the balls.

- If your primary focus is achieving a very fine, uniform particle size: Prioritize attrition by using smaller grinding media to increase surface area contact, which may require longer grinding times.

- If your primary focus is maximizing energy efficiency: Avoid operating at the highest possible speeds and ensure your ball charge is within the optimal 30-50% range to prevent wasted motion and energy.

By systematically adjusting these core parameters, you can transform your ball mill from a simple grinder into a precision engineering tool.

Summary Table:

| Parameter | Key Influence | Optimal Range / Considerations |

|---|---|---|

| Rotational Speed | Determines ball motion (cascading vs. centrifuging) | 65-75% of critical speed |

| Grinding Media Size | Larger balls for impact (coarse grinding); smaller for attrition (fine grinding) | Match size to feed material and desired product |

| Ball Charge (Filling Ratio) | Volume of media affecting collision frequency and energy | Typically 30-50% of mill volume |

| Material Properties | Hardness and initial size dictate required energy and media type | Softer materials favor attrition; harder materials need impact |

Ready to Optimize Your Milling Process?

Achieving the perfect balance of impact and attrition for your specific material is key to lab efficiency and product quality. The experts at KINTEK specialize in lab equipment and consumables, providing the right solutions for your grinding challenges.

We can help you select the ideal grinding media and optimize your ball mill parameters to save time, reduce energy costs, and achieve a superior particle size distribution.

Contact our technical team today for a personalized consultation and see how we can enhance your laboratory's capabilities.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- In which industry is a ball mill used? From Mining to Nanotech, Unlock Versatile Grinding

- How does a high-efficiency homogenizing mixer contribute to the preparation of Tobermorite and Xonotlite precursors?

- What is a mixer in biology? The Essential Tool for Homogeneous Samples

- What is the primary function of a ball mill in calcium thermal reduction? Optimize Your Raw Material Preparation

- What is the primary function of the grinding process in NCM-811 & beta-Li3PS4 preparation? Optimize Battery Performance

- What is the feed and product size of a ball mill? Achieve Fine to Ultra-Fine Grinding

- What is the primary function of mechanical grinding in 2G biomass pretreatment? Unlock High-Yield Conversion

- What is the primary function of mechanical grinding equipment in the physical modification of lignin?