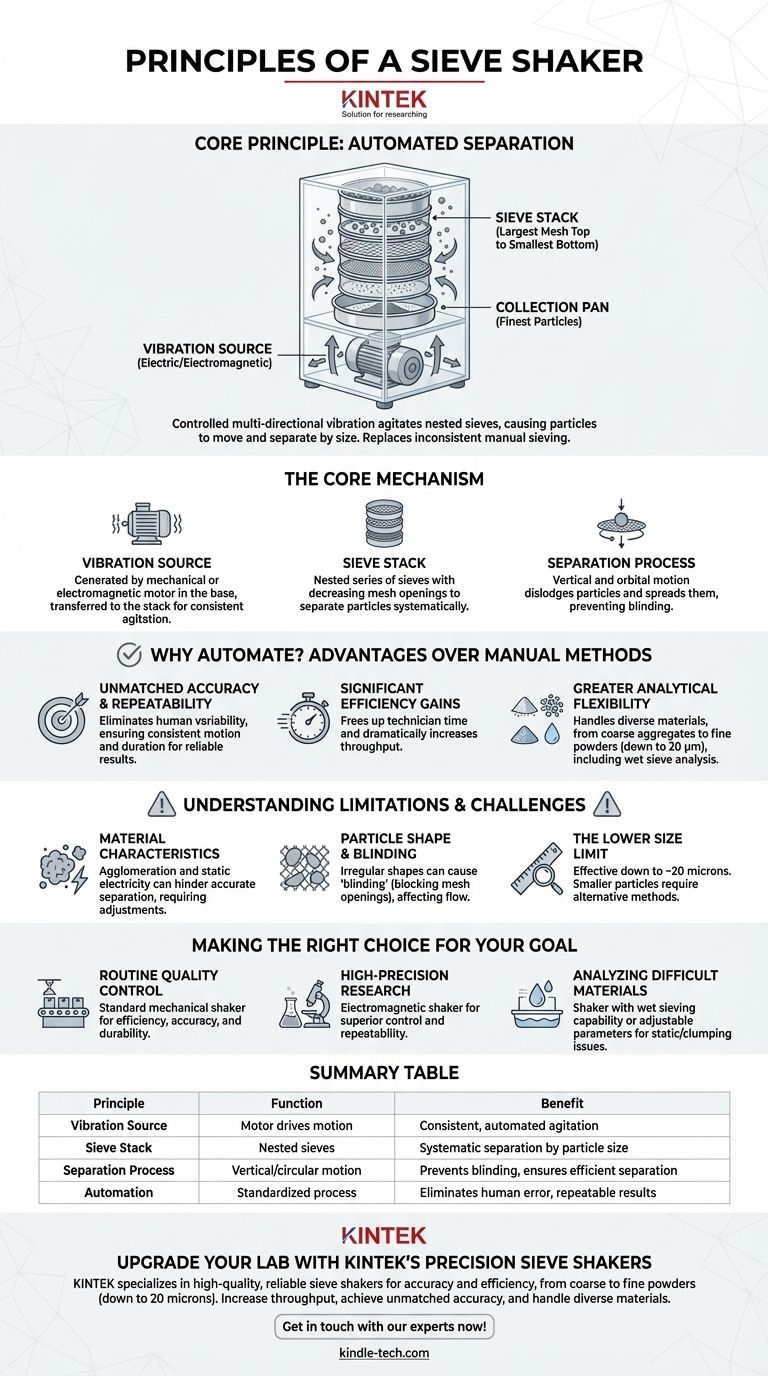

At its core, a sieve shaker operates by using a controlled vibration source, typically an electric or electromagnetic motor, to agitate a stack of test sieves. This agitation causes particles to move across the sieve mesh; particles smaller than the mesh openings pass through to the sieve below, while larger particles are retained. This systematic process separates a material sample by particle size, allowing for accurate and repeatable analysis.

The fundamental principle of a sieve shaker is to replace inconsistent manual sieving with a standardized, automated process. By applying controlled, multi-directional vibration, it ensures every particle is repeatedly tested against the sieve openings for highly efficient and accurate particle size separation.

The Core Mechanism: How Vibration Creates Separation

A sieve shaker's effectiveness comes from its ability to turn simple motion into a precise analytical outcome. The process relies on a few interconnected actions working in harmony.

The Vibration Source

The entire system is driven by a motor that sits in the shaker's base. This motor generates a consistent vibration that is transferred through the base to the entire stack of sieves mounted on top. For standard applications, a mechanical motor is used, while high-precision tests often utilize an electromagnetic drive for even greater control.

The Sieve Stack

A sieve shaker does not use a single sieve but a nested stack of test sieves. Each sieve in the stack has a mesh with openings of a specific size, arranged from the largest openings at the top to the smallest at the bottom, with a solid collection pan at the very end.

The Separation Process

As the shaker vibrates, the material sample placed in the top sieve is agitated. The optimal motion is a combination of vertical and circular (orbital) movement. The vertical tap helps to dislodge particles and prevent them from blocking the mesh openings, while the circular motion spreads the material and continuously presents new particles to the mesh for separation.

Why a Sieve Shaker Outperforms Manual Methods

While hand sieving is possible, an automated shaker provides significant advantages that are critical for any professional laboratory or quality control environment.

Unmatched Accuracy and Repeatability

Manual shaking is inherently inconsistent. The force, duration, and motion vary with every user and every test. A sieve shaker eliminates this variability by applying the exact same motion for the exact same amount of time, ensuring results are repeatable and reliable.

Significant Efficiency Gains

Automating the sieving process frees up valuable technician time and dramatically increases throughput. What would take many minutes of manual labor can be completed more accurately by a machine, allowing for more tests to be run in a day.

Greater Analytical Flexibility

Modern sieve shakers can handle a wide range of materials, from coarse aggregates down to fine powders measuring just 20 microns (µm). They can also be adapted for wet sieve analysis, which is necessary for materials that may be affected by static electricity or tend to agglomerate when dry.

Understanding the Practical Limitations

While powerful, the effectiveness of a sieve shaker is not absolute. Certain factors related to the equipment and the material itself can influence the final results.

Material Characteristics Matter

The nature of the material being tested is a primary factor. Materials that are prone to agglomeration (clumping together) or are affected by static electricity can be difficult to separate accurately. This may require adjusting vibration intensity or using wet sieving methods.

Particle Shape and Blinding

The ideal orbital motion is crucial for preventing a phenomenon known as "blinding," where particles of a certain size or shape get stuck in the mesh openings, blocking other particles from passing through. The combined vertical and circular motion is designed specifically to keep the mesh clear.

The Lower Size Limit

Sieve shakers are extremely effective for separating granular and powdery materials. However, their practical lower limit is around 20 microns. For analyzing particles smaller than this (sub-sieve size), other methods like laser diffraction or sedimentation analysis are required.

Making the Right Choice for Your Goal

Selecting and using a sieve shaker effectively depends on your specific analytical needs.

- If your primary focus is routine quality control: A standard mechanical sieve shaker offers the necessary efficiency, accuracy, and durability for most production environments.

- If your primary focus is high-precision research: An electromagnetic sieve shaker is the better choice, providing superior control and repeatability for analyzing fine powders or developing new materials.

- If your primary focus is analyzing difficult materials: Ensure your shaker allows for wet sieving or has adjustable motion parameters to overcome issues like static or particle clumping.

Ultimately, understanding the principles of a sieve shaker empowers you to move beyond simple separation and toward truly reliable particle size analysis.

Summary Table:

| Principle | Function | Benefit |

|---|---|---|

| Vibration Source | Motor (mechanical/electromagnetic) drives motion | Consistent, automated agitation |

| Sieve Stack | Nested sieves with decreasing mesh sizes | Systematic separation by particle size |

| Separation Process | Vertical and circular motion agitates particles | Prevents blinding, ensures efficient separation |

| Automation | Standardized shaking time and motion | Eliminates human error, ensures repeatable results |

Upgrade your lab's particle size analysis with KINTEK's precision sieve shakers.

Are you looking to replace inconsistent manual sieving with a standardized, automated process? KINTEK specializes in high-quality lab equipment, including reliable sieve shakers designed for accuracy and efficiency. Our shakers are ideal for laboratories and quality control environments that need repeatable results for materials ranging from coarse aggregates to fine powders (down to 20 microns).

We can help you:

- Increase throughput and free up technician time with automated operation.

- Achieve unmatched accuracy and repeatability for reliable quality control.

- Handle a wide range of materials, including options for wet sieve analysis.

Contact us today to find the perfect sieve shaker for your specific application and enhance your analytical capabilities.

Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What are types of sieve shakers? Choose the Right Agitation for Accurate Particle Analysis

- How do you maintain a sieve shaker? Ensure Accurate Particle Size Analysis Every Time

- Why is a benchtop shaker essential during the biosorption experiments of palladium ions (Pd2+)? Maximize Your Ion Yield

- How does a sieve shaker work? A Guide to Automated Particle Size Analysis

- How does a laboratory vibratory sieve shaker facilitate the microstructural study of gas-atomized alloy powders?

- What precautions should be taken during sieve analysis? Ensure Accurate & Repeatable Particle Size Results

- What is the function of sieving equipment in CuAlMn alloys? Master Pore Size Precision

- What is the purpose of a sieve shaker? Achieve Accurate & Repeatable Particle Size Analysis