At their core, the refrigerant fluids used in Ultra-Low Temperature (ULT) freezers are specialized gaseous compounds chosen for their ability to be easily liquefied under specific conditions. They are defined by properties like a high critical temperature and low critical pressure, which allow them to efficiently absorb and release heat. The most common modern refrigerants for these applications include natural hydrocarbons like R170 (Ethane) and R290 (Propane), as well as fluorocarbons like R23 (Trifluoromethane).

The central challenge of reaching ultra-low temperatures isn't solved by a single "super" refrigerant. Instead, ULT freezers use a multi-stage "cascade" system where two or more distinct refrigerant circuits work in tandem, each optimized for a specific temperature range.

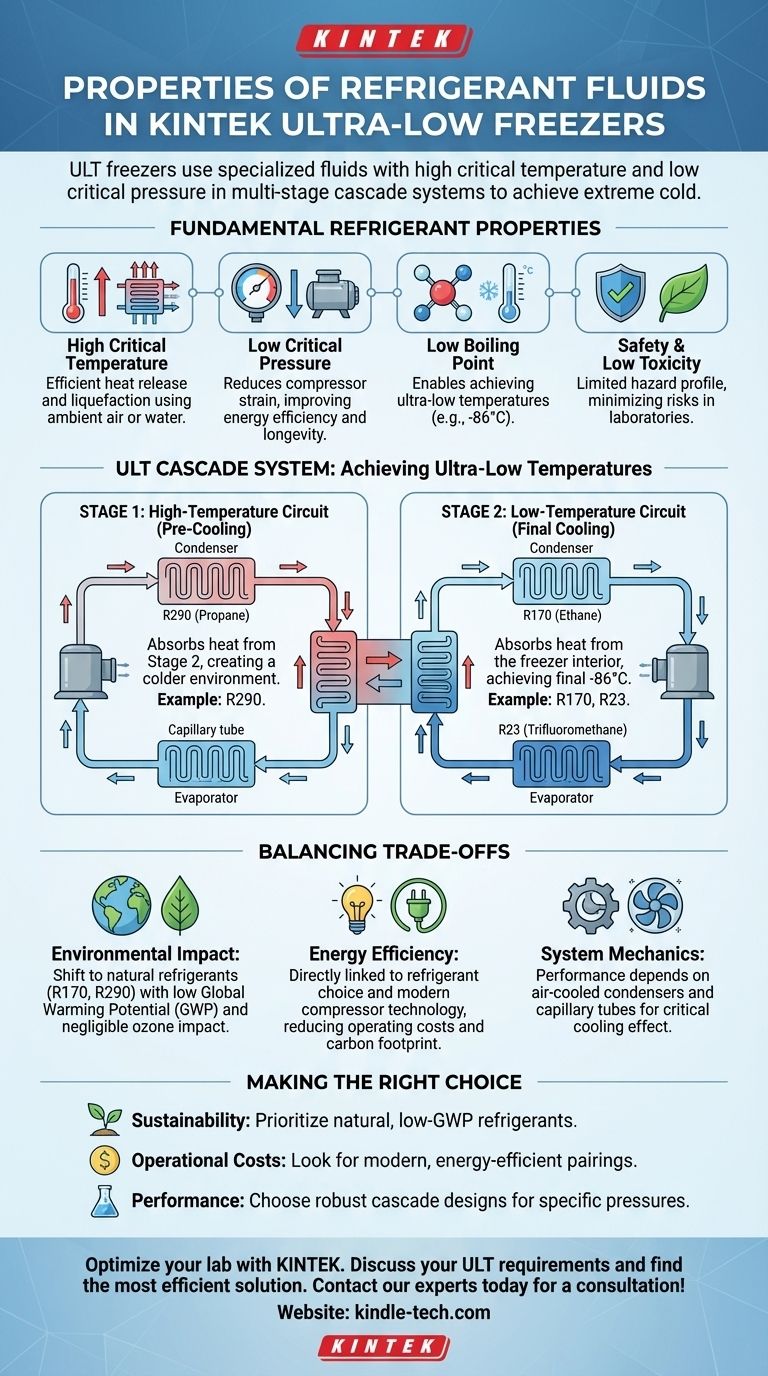

The Fundamental Properties of Refrigerants

To understand why specific fluids are chosen, we must first look at the ideal characteristics required for any refrigeration cycle. These properties dictate the efficiency, safety, and effectiveness of the entire system.

High Critical Temperature

The critical temperature is the highest temperature at which a gas can be converted back into a liquid simply by applying pressure. A high critical temperature ensures that the refrigerant can be easily liquefied in the condenser using ambient air or water, which is a crucial step in releasing the heat it has absorbed.

Low Critical Pressure

This is the minimum pressure needed to liquefy the gas at its critical temperature. A lower critical pressure means the system's compressor doesn't have to work as hard, leading to greater energy efficiency and reduced mechanical stress on the components.

Safety and Low Toxicity

Because these systems operate in laboratories and medical facilities, the refrigerants must have limited hazard and toxicity profiles. This minimizes risk to personnel and the surrounding environment in the event of a leak.

How Cascade Systems Achieve Ultra-Low Temperatures

A single refrigerant cannot efficiently bridge the massive temperature gap between a warm room and -86°C. ULT freezers solve this by using two independent but thermally connected refrigeration systems.

The First Stage (High-Temperature Circuit)

This initial circuit functions like a standard freezer. It uses a refrigerant like R290 (Propane) to absorb heat from the second circuit, effectively pre-cooling it. Its job is not to cool the chamber itself, but to create a colder environment for the next stage to work from.

The Second Stage (Low-Temperature Circuit)

This circuit is what produces the final ultra-low temperature inside the freezer cabinet. It uses a refrigerant with a much lower boiling point, such as R170 (Ethane) or R23 (Trifluoromethane). This circuit absorbs heat from the freezer's interior and transfers it to the first stage, which then expels it into the room.

Understanding the Trade-offs

The selection of refrigerants involves balancing performance with environmental and operational concerns. Modern advancements focus heavily on optimizing this balance.

Environmental Impact

Older refrigerants (CFCs and HCFCs) had a devastating impact on the ozone layer and a high global warming potential. Modern ULT freezers have shifted to natural refrigerants like R170 and R290 precisely because they have a negligible effect on the ozone layer and very low global warming potential.

Energy Efficiency

The choice of refrigerant is directly linked to energy consumption. Ongoing improvements in both compressor technology and the thermodynamic properties of these fluids are making ULT freezers significantly more energy-efficient, reducing both operating costs and their carbon footprint.

System Mechanics

The performance of the refrigerant fluid depends on the physical system. Heat is typically removed via air-cooled condensers—coils of copper or copper-aluminum tubing—with airflow driven by fans. The critical cooling effect happens when the high-pressure liquid refrigerant is expanded through capillary tubes, causing a rapid drop in temperature and pressure.

Making the Right Choice for Your Goal

Understanding these principles allows you to select a unit based on your primary objectives.

- If your primary focus is environmental sustainability: Prioritize freezers that use natural, low-GWP refrigerants like R170 and R290.

- If your primary focus is lowering operational costs: Look for models that pair modern, energy-efficient refrigerants with advanced compressor technology.

- If your primary focus is performance and reliability: Choose systems with robust cascade designs and components engineered to handle the specific pressures of their designated refrigerants.

Ultimately, an effective ULT freezer is a balanced system where the chemical properties of the refrigerants are perfectly matched to the mechanical engineering of the hardware.

Summary Table:

| Property | Why It Matters for ULT Freezers | Common Refrigerants |

|---|---|---|

| High Critical Temperature | Allows efficient heat release and liquefaction in the condenser. | R290 (Propane), R23 |

| Low Critical Pressure | Reduces compressor strain, improving energy efficiency and longevity. | R170 (Ethane), R290 |

| Low Boiling Point | Enables the system to achieve ultra-low temperatures (e.g., -86°C). | R170 (Ethane), R23 |

| Low Environmental Impact | Modern units use natural refrigerants with low Global Warming Potential (GWP). | R170, R290 |

Optimize your lab's cold storage with KINTEK's expertise. Selecting the right Ultra-Low Temperature freezer is critical for the integrity of your sensitive samples, your energy costs, and your sustainability goals. As your partner in laboratory equipment, KINTEK can help you navigate the technical specifications—from refrigerant properties to cascade system design—to find the perfect ULT solution for your specific needs in research, biobanking, or pharmaceutical storage.

Let's discuss your requirements and find the most efficient and reliable ULT freezer for your lab. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 28L Compact Upright Ultra Low Temperature Freezer for Laboratory

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

People Also Ask

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- What are the different types of ultra-low temperature freezers available? Choose the Right ULT Freezer for Your Lab

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- Why are ultra-low temperature freezers important in scientific research? Ensure Sample Integrity and Reproducibility