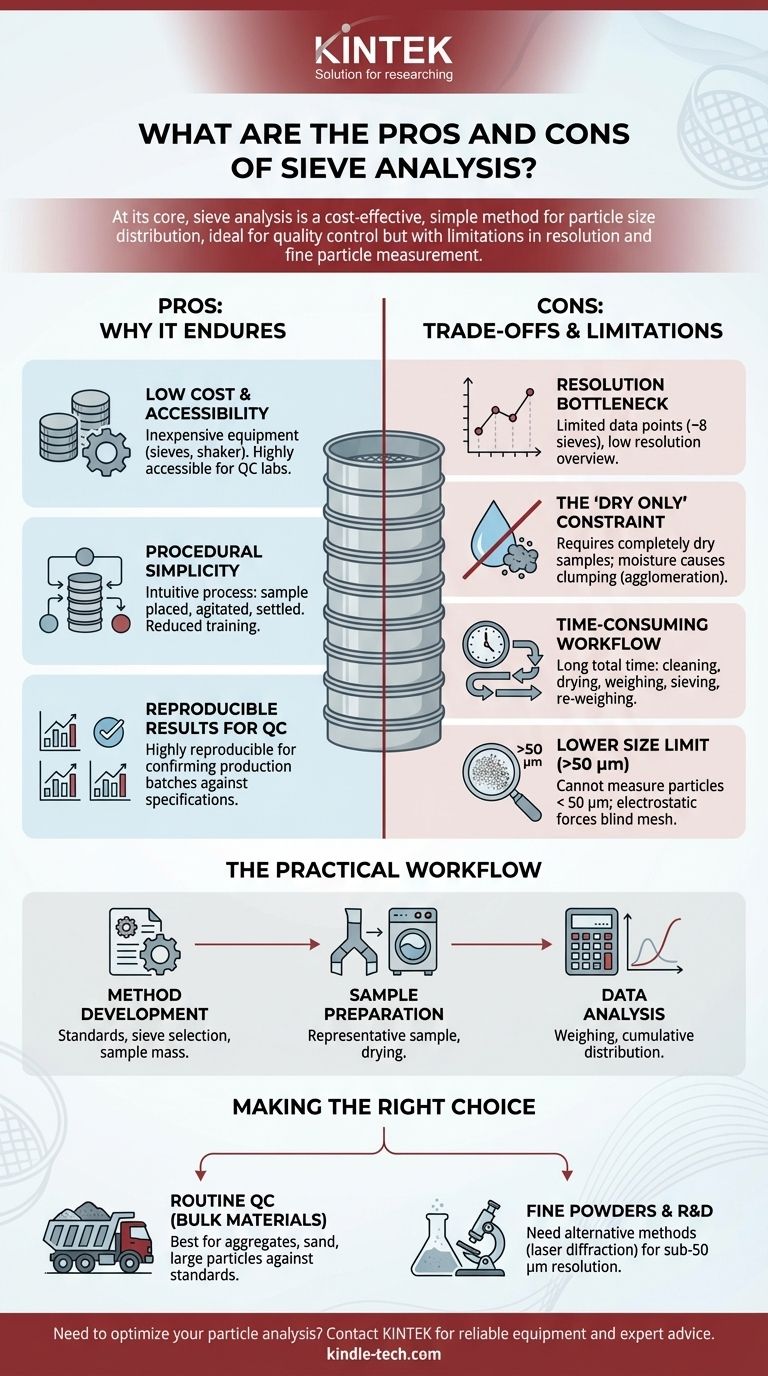

At its core, sieve analysis is a straightforward and cost-effective method for determining the particle size distribution of a granular material. Its primary advantages are its simplicity, low initial investment, and ability to generate reproducible results ideal for quality control. However, these benefits come with significant trade-offs, namely its limited resolution, an inability to measure particles smaller than about 50 micrometers (µm), and a requirement for the sample to be completely dry.

While valued for its simplicity and low cost, sieve analysis is best understood as a tool for general classification, not high-precision measurement. Its true value is realized in routine quality control of bulk materials, whereas its limitations become critical when analyzing fine powders or requiring detailed distribution data.

The Fundamental Appeal: Why Sieve Analysis Endures

Sieve analysis, also known as a gradation test, remains a cornerstone of material analysis in many industries, particularly civil engineering and agriculture. Its persistence is due to a few powerful, practical advantages.

### Low Cost and Accessibility

The required equipment—a set of standardized sieves, a balance, and ideally a mechanical sieve shaker—is inexpensive compared to advanced particle analysis technologies. This makes the method highly accessible for virtually any quality control lab.

### Procedural Simplicity

The physical process is intuitive. A weighed sample is placed on the top sieve of a stack, and the stack is agitated until the particles have settled onto the sieves they cannot pass through. This operational simplicity reduces the need for highly specialized operator training.

### Reproducible Results for QC

For a given material and a standardized procedure, sieve analysis delivers highly reproducible results. This makes it an excellent tool for routine quality control, where the goal is to confirm that a production batch falls within a predefined specification, not to discover the precise particle distribution.

Understanding the Trade-offs and Limitations

The simplicity of sieve analysis is also the source of its primary weaknesses. An expert understands that these are not just minor inconveniences but fundamental constraints that define where the method can and cannot be used.

### The Resolution Bottleneck

A standard sieve stack contains a limited number of sieves, typically a maximum of eight. This means your final particle size distribution curve is built from only eight data points. This provides a low-resolution overview, which is often insufficient for research or the characterization of materials with complex distributions.

### The "Dry Only" Constraint

Sieve analysis relies on gravity and agitation for particles to pass through mesh openings. If the sample is damp, particles will clump together (agglomerate), blocking the sieve openings and rendering the results meaningless. This means a mandatory, and often time-consuming, pre-drying step is required for many samples.

### The "Time-Consuming" Paradox

While the mechanical shaking process itself may only last 10-15 minutes, the total time required for a single analysis is much longer. The complete workflow includes cleaning and weighing empty sieves, sample preparation (drying), precise weighing of the sample, the sieving run, and finally, carefully weighing the material retained on each individual sieve. This multi-step process can easily take hours.

### The Lower Size Limit

Woven-wire sieves are not practical for measuring particles smaller than approximately 50 µm. Below this threshold, electrostatic forces cause fine particles to blind the mesh. For analyzing fine powders like pigments, pharmaceuticals, or cements, alternative methods like laser diffraction are necessary.

The Practical Workflow: More Than Just Shaking

Understanding the full workflow reveals the hidden complexities behind the method's apparent simplicity. Executing a proper sieve analysis requires careful preparation and adherence to a strict procedure.

### Method Development is Crucial

You cannot simply begin shaking a sample. An effective analysis requires developing a method based on industry standards (like ASTM or ISO), selecting the correct sieve sizes for the expected particle range, and determining the appropriate sample mass to avoid overloading the sieves.

### Sample Preparation is Non-Negotiable

The initial sample taken from a large batch must be representative. This often requires a process of sample splitting or quartering. Following that, the sample must be dried to a constant weight to ensure moisture does not skew the results.

### Data Analysis and Interpretation

The final output of the physical test is a series of weights—the mass of material retained on each sieve. This raw data must then be calculated and plotted as a cumulative distribution curve to become useful for quality assessment or material specification.

Making the Right Choice for Your Application

Ultimately, the decision to use sieve analysis depends entirely on your goal. It is a powerful tool when used within its proper context and a deeply flawed one when misapplied.

- If your primary focus is routine quality control of bulk materials: Sieve analysis is likely your most reliable and cost-effective choice for checking aggregates, sand, grains, or other large-particle products against a set standard.

- If your primary focus is detailed characterization of fine powders: You must look to alternative methods like laser diffraction or dynamic light scattering, as sieve analysis lacks the necessary resolution and range for sub-50 µm particles.

- If your primary focus is research and development: Use sieve analysis for initial, broad assessments of granular materials, but be prepared to supplement it with higher-resolution techniques to gain deeper insights into particle behavior.

By understanding these practical trade-offs, you can confidently determine if this classic technique meets the specific demands of your project.

Summary Table:

| Pros | Cons |

|---|---|

| Low initial cost and accessible equipment | Limited resolution (only ~8 data points) |

| Simple, intuitive procedure | Cannot measure particles < 50 µm |

| Highly reproducible for QC | Requires completely dry samples |

| Excellent for bulk material classification | Time-consuming multi-step workflow |

Need to optimize your particle analysis workflow? KINTEK specializes in providing reliable lab equipment and consumables for accurate material testing. Whether you're performing routine sieve analysis or require more advanced particle characterization solutions, our experts can help you select the right tools for your laboratory's specific needs. Contact us today to discuss how we can support your quality control and research goals!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- Why is a laboratory sieving system required for bentonite in coatings? Ensure Flawless Surface Performance

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis