The primary risks of modern biomass boilers center on air quality emissions, the sustainability of the fuel source, and significant operational demands. While a vast improvement over open-fire burning, these systems still release pollutants like particulate matter and require a carefully managed supply chain to be genuinely eco-friendly, alongside a greater hands-on commitment than conventional heating systems.

While often promoted as a green alternative, the true risk of a biomass boiler lies not in the technology itself, but in how it is managed. The environmental and health risks are directly tied to the quality of the fuel, the efficiency of the combustion, and the sustainability of the supply chain.

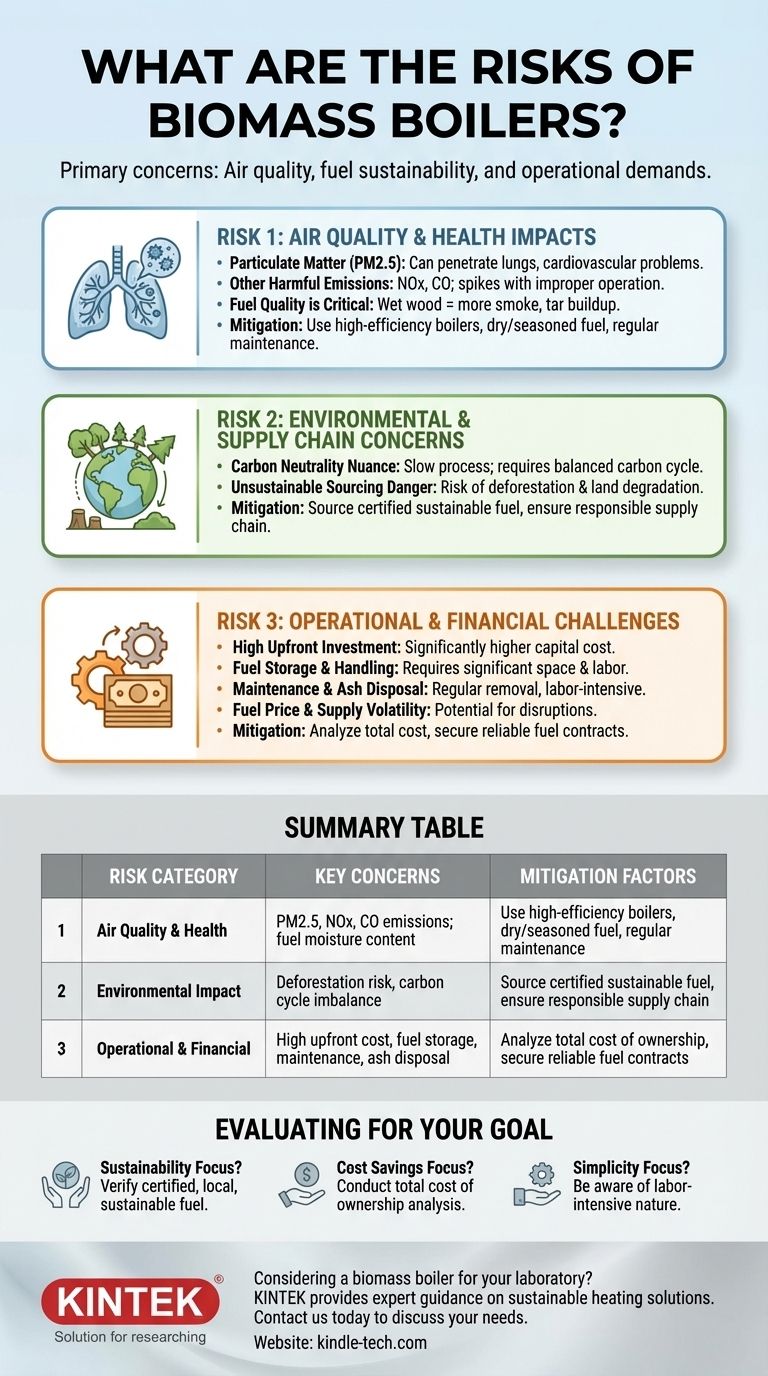

Risk 1: Air Quality and Health Impacts

Even with modern technology, burning organic matter releases substances into the air. The level of risk is determined by the quality of the boiler, the fuel used, and the system's maintenance.

Particulate Matter (PM2.5)

The most significant health risk is the emission of fine particulate matter (PM2.5). These microscopic particles can penetrate deep into the lungs and enter the bloodstream, contributing to respiratory and cardiovascular problems.

While modern boilers are designed to minimize these emissions through controlled combustion, they still produce more PM2.5 than natural gas or oil boilers. The level of emissions can increase dramatically if the boiler is not operating at optimal temperature or is poorly maintained.

Other Harmful Emissions

Biomass combustion also produces Nitrogen Oxides (NOx) and Carbon Monoxide (CO). High-efficiency boilers manage these, but improper operation or low-quality fuel can lead to spikes in these harmful gases.

The Critical Role of Fuel Quality

The reference to "moist wood" causing more smoke is a crucial point that applies directly to modern boilers. The moisture content of the fuel is paramount.

Wet or "green" wood burns incompletely, creating significantly more smoke, particulate matter, and tar buildup within the system. Using properly seasoned or pelletized fuel with low moisture content is non-negotiable for safe and efficient operation.

Risk 2: Environmental and Supply Chain Concerns

The "green" credentials of biomass energy are entirely dependent on a responsible and sustainable fuel cycle. Without it, the environmental benefits can be negated.

The Nuance of "Carbon Neutrality"

Biomass is considered carbon neutral because the carbon released during combustion is theoretically reabsorbed by new plant growth. However, this is a slow process.

If fuel is sourced by clear-cutting forests without a robust replanting strategy, the system becomes a net carbon contributor for decades. True neutrality depends on a balanced carbon cycle.

The Danger of Unsustainable Sourcing

The risk of deforestation and land degradation mentioned in the references is very real if the fuel supply chain is not managed correctly.

To mitigate this, you must ensure your fuel comes from a certified sustainable source. This includes responsibly managed forests, agricultural residues, or purpose-grown energy crops that do not displace food production or harm biodiversity.

Understanding the Trade-offs: Operational and Financial Risks

Beyond environmental factors, biomass boilers introduce practical challenges that differ significantly from conventional systems.

High Upfront Investment

Biomass boiler systems have a significantly higher capital cost than their gas or oil counterparts. While government incentives may exist, the initial financial outlay is a major consideration.

Fuel Storage and Handling

Unlike gas piped directly to a property, biomass fuel (pellets or wood chips) requires significant physical storage space. The fuel must be kept dry to maintain quality.

Furthermore, these systems require labor. Even automated systems need their hoppers filled, and manual systems require regular loading, representing a time and effort commitment not present with fossil fuel boilers.

Maintenance and Ash Disposal

Burning solid fuel creates ash that must be removed and disposed of regularly. Failure to do so will impair the boiler's efficiency and lifespan. This hands-on maintenance is a key operational difference and a hidden cost.

Fuel Price and Supply Volatility

While wood can be cheaper than fossil fuels, its price and availability can be more volatile and subject to local supply chain disruptions. Securing a reliable, long-term fuel contract is a critical step in mitigating financial risk.

Evaluating Biomass Boilers for Your Goal

To make an informed decision, you must weigh these risks against your specific priorities.

- If your primary focus is environmental sustainability: Your top priority must be verifying a certified, local, and truly sustainable fuel source to ensure you are not contributing to deforestation or a net carbon increase.

- If your primary focus is long-term cost savings: You must conduct a thorough total cost of ownership analysis, factoring in the high capital cost, maintenance, and the potential for fuel price volatility against projected savings.

- If your primary focus is operational simplicity: Be aware that a biomass boiler is fundamentally more labor-intensive than a gas, oil, or electric system and may not be the right fit.

Ultimately, a well-managed biomass boiler can be a viable solution, but success depends on a clear-eyed assessment of its inherent risks and responsibilities.

Summary Table:

| Risk Category | Key Concerns | Mitigation Factors |

|---|---|---|

| Air Quality & Health | PM2.5, NOx, CO emissions; fuel moisture content | Use high-efficiency boilers, dry/seasoned fuel, regular maintenance |

| Environmental Impact | Deforestation risk, carbon cycle imbalance | Source certified sustainable fuel, ensure responsible supply chain |

| Operational & Financial | High upfront cost, fuel storage, maintenance, ash disposal | Analyze total cost of ownership, secure reliable fuel contracts |

Considering a biomass boiler for your laboratory or facility? KINTEK specializes in lab equipment and consumables, providing expert guidance on sustainable heating solutions. Our team can help you evaluate the risks and benefits specific to your operational needs, ensuring you select a system that aligns with your environmental and efficiency goals. Contact us today to discuss how we can support your laboratory's energy and equipment requirements!

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

People Also Ask

- What role does an autoclave play in simulating PWR conditions? Advanced Material Validation for Nuclear Safety

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS

- What roles do autoclaves play in MFI zeolite synthesis? Master Hydrothermal Crystalline Growth

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation