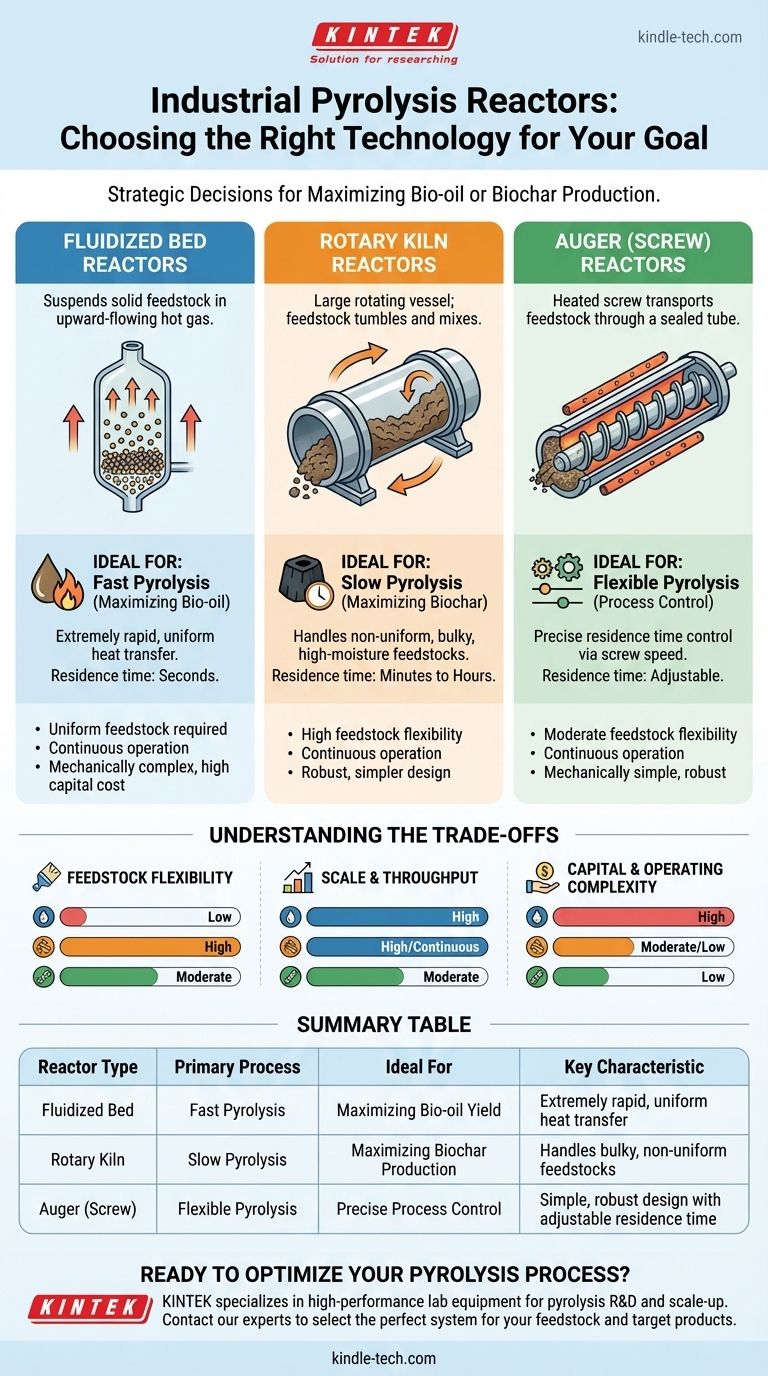

While dozens of pyrolysis reactor designs exist, industrial-scale operations predominantly rely on three core types: Fluidized Bed, Rotary Kiln, and Auger (or Screw) reactors. Each is engineered to optimize the conversion of biomass or waste into specific products by precisely controlling heat transfer and material residence time.

The choice of a pyrolysis reactor is not a matter of preference but a strategic engineering decision. Your desired end-product—whether it's high-yield bio-oil or high-quality biochar—will fundamentally dictate which reactor technology is the correct tool for the job.

The Core Reactor Technologies

Industrial pyrolysis centers on technologies that can handle large volumes of feedstock continuously and efficiently. While other types like fixed-bed or batch reactors exist, they are more common in laboratory or small-scale applications.

Fluidized Bed Reactors

A fluidized bed reactor suspends solid feedstock particles in an upward-flowing stream of hot gas, creating a "fluidized" mixture that behaves like a liquid. This ensures extremely rapid and uniform heat transfer to every particle.

This exceptional heat transfer makes fluidized beds the industry standard for fast pyrolysis, a process designed to maximize the production of liquid bio-oil.

Rotary Kiln Reactors

A rotary kiln is a large, rotating cylindrical vessel. As the kiln slowly rotates, the feedstock tumbles and mixes, ensuring all material is gradually and evenly exposed to heat.

This design is robust and excellent for handling non-uniform, bulky, or high-moisture feedstocks. Its typically longer residence times make it well-suited for slow pyrolysis, where the primary goal is to produce biochar.

Auger (Screw) Reactors

An auger reactor uses one or more heated screws to transport feedstock through a sealed trough or tube. The speed of the screw directly controls the residence time, while the temperature of the tube walls provides the heat.

This design offers precise control over the process, allowing operators to fine-tune conditions. Its mechanical simplicity and controlled material flow make it a versatile option for a range of feedstocks and production goals, fitting between fast and slow pyrolysis.

How Process Goals Dictate Reactor Choice

The "best" reactor is the one that creates the ideal conditions—heating rate and residence time—for your target product. Pyrolysis is not a single process; it's a spectrum.

The Goal: Maximizing Bio-oil (Fast Pyrolysis)

To maximize liquid bio-oil, you must heat the feedstock to high temperatures (400–700°C) very quickly and then rapidly cool the resulting vapors. This requires a residence time of only a few seconds.

Fluidized bed reactors excel at this. Their ability to deliver near-instantaneous heat to small particles is unmatched, making them the superior choice for high-throughput bio-oil production.

The Goal: Maximizing Biochar (Slow Pyrolysis)

To create stable, high-carbon biochar, the feedstock must be heated at a much slower rate to lower temperatures (300–400°C) and held there for an extended period, from many minutes to hours.

Rotary kilns are ideal for this process. Their tumbling action prevents hot spots and ensures the entire mass is slowly and evenly carbonized. Simple fixed-bed reactors are also used for slow pyrolysis, especially at smaller scales.

Understanding the Trade-offs

No single reactor is perfect for every situation. The decision involves balancing performance with practical operational constraints.

Feedstock Flexibility

Rotary kilns are highly tolerant of diverse particle sizes and shapes, from wood chips to shredded plastics. In contrast, fluidized bed reactors require a more uniform and finely ground feedstock to ensure proper fluidization.

Scale and Throughput

Fluidized bed and rotary kiln reactors are designed for continuous operation and are the workhorses of large, industrial plants processing tons of material per hour. Fixed-bed or batch reactors are inherently limited in scale and are better suited for specialized, low-volume production.

Capital and Operating Complexity

Fluidized bed systems are mechanically complex. They require powerful blowers, advanced gas handling (cyclones), and precise control systems, making them more expensive to build and operate. Auger and rotary kiln reactors are often simpler and more mechanically robust.

Making the Right Choice for Your Goal

To select the correct technology, start by defining your primary objective.

- If your primary focus is high-volume bio-oil production: A fluidized bed reactor is the industry standard due to its superior heat transfer rates, which are essential for fast pyrolysis.

- If your primary focus is producing biochar from varied or difficult feedstock: A rotary kiln offers the robustness, mixing, and longer residence times needed for effective slow pyrolysis.

- If your primary focus is process control and adaptability at a moderate scale: An auger reactor provides precise control over residence time, making it uniquely flexible for optimizing either bio-oil or biochar production.

Selecting the right reactor is not about finding the 'best' technology, but about aligning the engineering design with your specific production goals.

Summary Table:

| Reactor Type | Primary Process | Ideal For | Key Characteristic |

|---|---|---|---|

| Fluidized Bed | Fast Pyrolysis | Maximizing Bio-oil Yield | Extremely rapid, uniform heat transfer |

| Rotary Kiln | Slow Pyrolysis | Maximizing Biochar Production | Handles bulky, non-uniform feedstocks |

| Auger (Screw) | Flexible Pyrolysis | Precise Process Control | Simple, robust design with adjustable residence time |

Ready to optimize your pyrolysis process? The right reactor technology is critical to achieving your production goals for bio-oil, biochar, or syngas. KINTEK specializes in high-performance lab equipment and consumables for pyrolysis R&D and scale-up. Our experts can help you select the perfect system for your specific feedstock and target products. Contact our team today to discuss your project and discover how KINTEK's solutions can enhance your laboratory's efficiency and success.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Which ores undergo calcination? A Guide to Carbonate and Hydrated Ore Processing

- What are the feedstocks used in pyrolysis? Unlock the Potential of Diverse Organic Materials

- Why is gasification better than pyrolysis? Maximize Energy Output vs. Create Valuable Products

- What are the outputs of pyrolysis? Unlocking the Solid, Liquid, and Gas Products from Thermal Decomposition

- What are the different types of pyrolysis reactors? Choose the Right Reactor for Your Process

- What is the temperature range for fast pyrolysis? Optimize Bio-Oil Yield from Biomass

- How efficient is pyrolysis? A Strategic Guide to Maximizing Output

- What is the product composition of pyrolysis? Unlock the Potential of Biochar, Bio-Oil, and Syngas