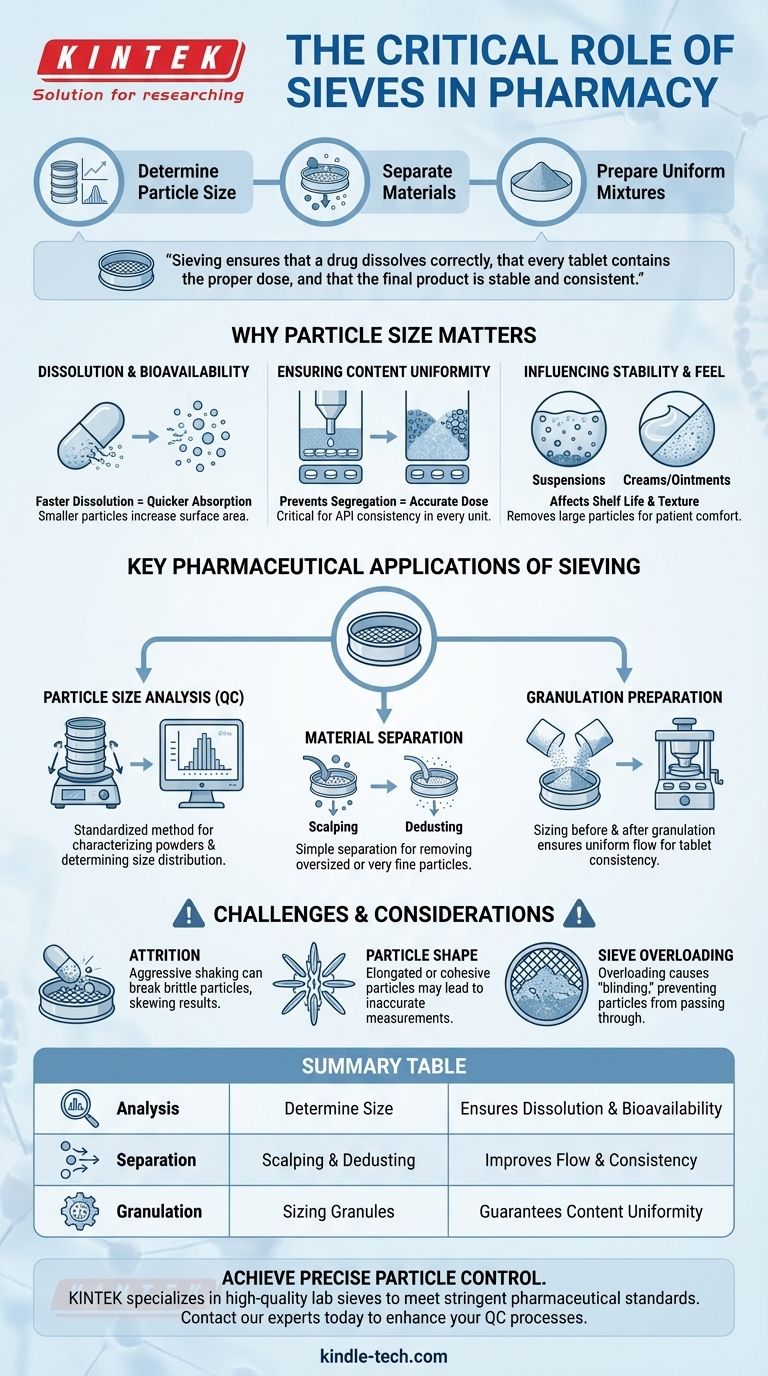

In pharmacy, sieves are indispensable tools used for three core functions: determining particle size distribution, separating materials, and preparing uniform mixtures for drug products. These actions are not merely procedural; they are fundamental quality control steps that directly influence the safety, efficacy, and consistency of medications, from raw ingredients to the final dosage form.

The control of particle size through sieving is a cornerstone of pharmaceutical science. It ensures that a drug dissolves correctly in the body, that every tablet contains the proper dose, and that the final product is stable and consistent.

The Critical Role of Particle Size in Pharmaceuticals

Understanding the function of sieves requires first understanding why particle size is one of the most critical physical characteristics of a pharmaceutical powder. Seemingly minor variations can have significant consequences for a drug's performance.

Impact on Drug Dissolution and Bioavailability

The rate at which a drug is absorbed by the body—its bioavailability—is heavily dependent on how quickly it dissolves.

Smaller particles possess a larger surface area relative to their volume. This increased surface area allows the drug to dissolve faster in the gastrointestinal tract, leading to quicker absorption and a more predictable therapeutic effect. Sieving is used to ensure the particle size is within the optimal range for the desired dissolution profile.

Ensuring Content Uniformity

In dosage forms like tablets and capsules, it is vital that every single unit contains the exact same amount of the Active Pharmaceutical Ingredient (API). This is known as content uniformity.

If a powder mixture contains particles of widely different sizes, the smaller particles can segregate from the larger ones during handling and processing. This can lead to some tablets having too much API (risk of toxicity) and others having too little (lack of efficacy). Sieving ensures a narrow, uniform particle size distribution, preventing segregation and guaranteeing dose accuracy.

Influencing Formulation Stability and Feel

Particle size also dictates the physical characteristics of a finished product.

In liquid suspensions, particle size affects the rate at which solids settle, impacting the product's shelf life and dose uniformity. In semi-solid preparations like creams and ointments, excessively large particles can cause a gritty texture, which is undesirable for patient use. Sieving is used to remove these large particles.

Key Pharmaceutical Applications of Sieving

Given the importance of particle size, pharmaceutical scientists and manufacturers employ sieving in several distinct applications throughout the development and production process.

Particle Size Analysis (Sieve Analysis)

This is a primary quality control (QC) method for characterizing powders. A standardized stack of sieves, each with a progressively smaller mesh opening, is placed on a mechanical shaker.

A weighed sample of powder is placed on the top sieve. The shaker agitates the stack for a set time, causing particles to pass through the apertures until they are retained on a sieve with a mesh too fine for them to pass. By weighing the powder retained on each sieve, one can determine the particle size distribution of the sample.

Material Separation and Fractioning

Sieving is a simple and effective method for physical separation.

Scalping is the process of using a large-mesh sieve to remove a small number of oversized particles or foreign contaminants from a raw material. Conversely, dedusting uses a fine-mesh sieve to remove unwanted very fine particles that can hinder powder flow during manufacturing.

Preparation for Granulation and Compression

Many tablets are not made from simple powders but from granules. Granulation is a process where fine powders are agglomerated into larger, more free-flowing granules.

Sieving is used both before and after granulation. It ensures the starting powder is the correct size, and it is used to size the final granules to ensure they flow uniformly into the tablet press, a critical factor for producing tablets of consistent weight and hardness.

Understanding the Trade-offs and Limitations

While fundamental, sieve analysis is not without its limitations. It is a mechanical process with inherent variables that must be controlled.

Issues with Attrition

The aggressive shaking motion used in sieve analysis can cause brittle particles to break down (attrition). This can artificially skew the results toward a finer particle size distribution than what is actually present in the original sample.

Challenges with Cohesive or Elongated Particles

Sieving works best for particles that are roughly spherical and non-sticky.

Very fine, cohesive powders may clump together and fail to pass through mesh openings they otherwise would fit through. Similarly, needle-shaped or elongated particles may pass through a mesh end-on, leading to an inaccurate measurement of their true size.

Sieve Loading and Analysis Time

For accurate results, the amount of powder loaded onto each sieve must not be excessive. Overloading a sieve can prevent particles from reaching the mesh surface, a phenomenon known as blinding, which traps them on an upper sieve and invalidates the analysis. The process can also be more time-consuming compared to modern methods like laser diffraction, though it remains a recognized pharmacopeial standard.

Applying Sieving to Your Pharmaceutical Goal

The specific application of sieving depends entirely on your objective within the pharmaceutical lifecycle, from early-stage research to large-scale production.

- If your primary focus is Quality Control (QC): Use standardized sieve analysis as a reliable, pharmacopeia-accepted method to verify that raw materials and in-process granules meet particle size specifications.

- If your primary focus is Formulation Development (R&D): Use sieves to fractionate powders to study how specific particle size ranges impact drug dissolution, bioavailability, and the physical feel of topical products.

- If your primary focus is Manufacturing: Employ sieving for scalping and dedusting to improve powder flow, ensure uniform die filling, and produce consistent, high-quality tablets and capsules batch after batch.

Ultimately, the humble sieve serves as a powerful tool for controlling the physical properties that underpin the safety and effectiveness of modern medicines.

Summary Table:

| Application | Primary Function | Key Impact |

|---|---|---|

| Particle Size Analysis | Determine particle size distribution | Ensures drug dissolution and bioavailability |

| Material Separation | Scalping (remove oversize) & Dedusting (remove fines) | Improves powder flow and manufacturing consistency |

| Granulation Preparation | Sizing powders before and after granulation | Guarantees content uniformity in tablets and capsules |

Achieve precise particle control for your pharmaceutical products.

Whether you are in R&D, Quality Control, or Manufacturing, proper sieving is fundamental to ensuring drug safety, efficacy, and batch-to-batch consistency. KINTEK specializes in high-quality lab sieves and equipment designed to meet stringent pharmaceutical standards.

Let us help you enhance your quality control processes. Contact our experts today to find the perfect sieving solution for your laboratory's needs.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Laboratory Single Horizontal Jar Mill

People Also Ask

- What is the purpose of using wide-aperture sieving screens? Optimize Garden Waste Pretreatment for Quality Pellets

- What is a sieve in a laboratory? A Guide to Precision Particle Size Analysis

- How do you calculate sieve mesh size? Use Official Standards for Accurate Particle Analysis

- What are the types of sieves used in pharmaceutical industry? Find the Right Sieving Solution for Your Lab

- What is sieving filtering? Master the Key Differences for Accurate Material Separation

- What is sieve analysis also known as? Understanding Gradation Tests for Particle Size Distribution

- What are the uses of sieves in laboratory? Ensure Material Quality and Consistency

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency