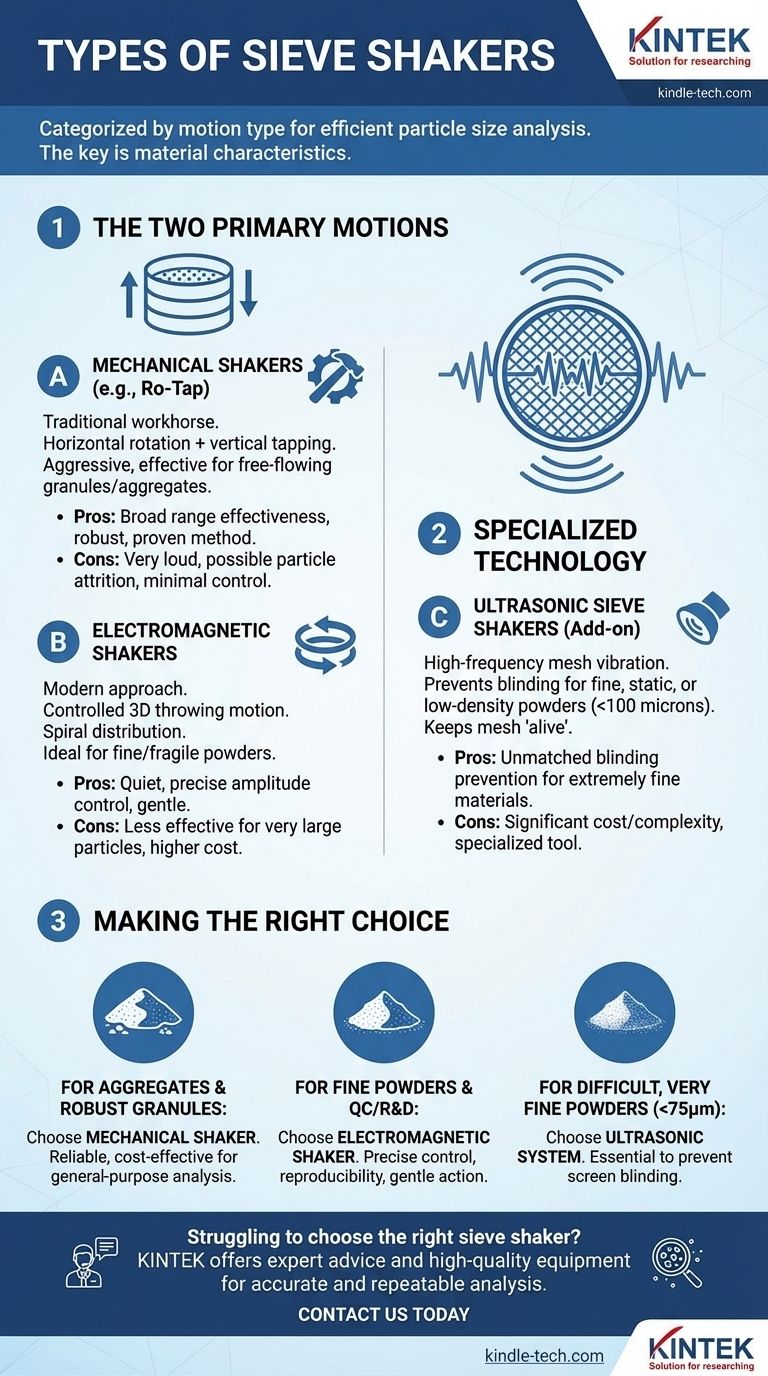

At their core, sieve shakers are categorized by the type of motion they impart to the test sieves. The two primary technologies used for particle size analysis are mechanical shakers, which use a physical tapping and rotating action, and electromagnetic shakers, which use a controlled 3D throwing motion. Specialized systems, such as ultrasonic shakers, also exist for challenging fine powders.

The most critical factor in choosing a sieve shaker is not the machine itself, but the characteristics of your material. The goal is to select a shaking motion that ensures each particle has the maximum opportunity to pass through the sieve openings without damaging the particles or causing screen blinding.

The Two Primary Sieve Shaker Motions

The effectiveness of a particle size analysis depends entirely on using the correct agitation method. The two main approaches, mechanical and electromagnetic, solve this problem in fundamentally different ways.

Mechanical Shakers: Tapping and Rotation

Mechanical shakers are the traditional workhorses of the industry. The most common design, often referred to by the brand name "Ro-Tap," combines two distinct movements.

It produces a horizontal, circular motion to distribute the material across the sieve mesh. Simultaneously, a hammer mechanism delivers a vertical tapping motion to the top of the sieve stack, jarring particles loose and preventing the mesh from clogging (an effect known as blinding).

This aggressive combination is highly effective for a wide range of free-flowing granular materials and aggregates.

Electromagnetic Shakers: 3D Throwing Motion

Electromagnetic shakers represent a more modern approach, offering greater control and quieter operation. These units use a powerful electromagnet to create a 3D throwing motion.

This motion moves the sample both vertically and horizontally, causing it to spiral across the sieve surface. This ensures particles are repeatedly tested against the mesh openings.

The key advantage is the ability to precisely control the vibration amplitude (the height of the "throw"). This makes electromagnetic shakers ideal for separating fine powders and fragile materials that could be damaged by an aggressive mechanical tapper.

Specialized Sieve Shaker Technologies

For materials that are particularly difficult to separate, specialized technologies are required to overcome issues like static electricity or particle agglomeration.

Ultrasonic Sieve Shakers: High-Frequency Vibration

Ultrasonic systems are typically not standalone shakers but rather an addition to another system, often an electromagnetic one. They use a transducer to induce high-frequency, low-amplitude vibration directly into the sieve mesh itself.

This micro-vibration is extremely effective at preventing blinding when working with very fine, low-density, or electrostatically charged powders (often sub-100 microns). It essentially keeps the mesh "alive" and prevents particles from sticking to the wires.

Understanding the Trade-offs

Choosing a shaker involves balancing performance, material type, and operational requirements. Each technology has distinct advantages and disadvantages.

Mechanical Shakers: The Workhorse

- Pros: Highly effective for a broad range of particle sizes, robust and durable, and a long-established, proven method.

- Cons: Very loud during operation, can cause attrition (particle breakdown) in friable materials, and offers minimal control over shaking parameters.

Electromagnetic Shakers: Precision and Control

- Pros: Very quiet operation, allows for precise and repeatable control of vibration amplitude, and is excellent for fine or delicate particles.

- Cons: May be less effective for very large, heavy particles that require aggressive tapping, and typically comes at a higher initial cost.

Ultrasonic Systems: The Specialist

- Pros: Unmatched at preventing screen blinding with extremely fine or static-prone powders, enabling analysis of materials that would otherwise be impossible to sieve.

- Cons: Adds significant cost and complexity to the setup; it is a specialized tool for specific problems, not a general-purpose solution.

Making the Right Choice for Your Material

Your final decision should be driven by the properties of your sample and your analytical goals.

- If your primary focus is general-purpose analysis of aggregates, sands, or robust granules: A mechanical "tapping" shaker is a reliable and cost-effective choice.

- If your primary focus is quality control or R&D with fine powders or friable materials: An electromagnetic shaker provides the necessary control, reproducibility, and gentle action.

- If your primary focus is separating difficult, very fine powders (e.g., <75 microns) that cause screen blinding: An ultrasonic system is the necessary tool to achieve an accurate separation.

Ultimately, selecting the correct sieve shaker ensures your particle size analysis results are both accurate and repeatable.

Summary Table:

| Shaker Type | Primary Motion | Best For | Key Advantage |

|---|---|---|---|

| Mechanical (e.g., Ro-Tap) | Horizontal rotation + vertical tapping | Aggregates, sands, robust granules | Proven, effective for a wide range of materials |

| Electromagnetic | Controlled 3D throwing motion | Fine powders, fragile materials, R&D/QC | Precise amplitude control, quiet, gentle |

| Ultrasonic (Add-on) | High-frequency mesh vibration | Extremely fine, static-prone powders (<75µm) | Prevents screen blinding for difficult materials |

Struggling to choose the right sieve shaker for your specific materials?

The wrong agitation method can lead to inaccurate results, screen blinding, or even damage to your samples. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert advice and high-quality sieve shakers.

We can help you:

- Select the perfect shaker (mechanical, electromagnetic, or ultrasonic) based on your material's properties.

- Achieve accurate and repeatable particle size analysis for reliable quality control and R&D.

- Optimize your sieving process to save time and improve efficiency.

Contact us today via the form below, and our experts will guide you to the ideal solution for your laboratory's particle analysis challenges.

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Oscillating Orbital Shaker

People Also Ask

- What are the applications of sieving machine? From Mining to Pharmaceuticals

- What is the principle of sieving machine? Achieve Accurate Particle Size Separation

- What does a vibrating sieve do? Automate Particle Size Analysis for Accurate Results

- What is the operating procedure of a sieve shaker? Master Accurate Particle Size Analysis

- What is the speed of a sieving machine? Optimize Vibration for Maximum Efficiency and Accuracy