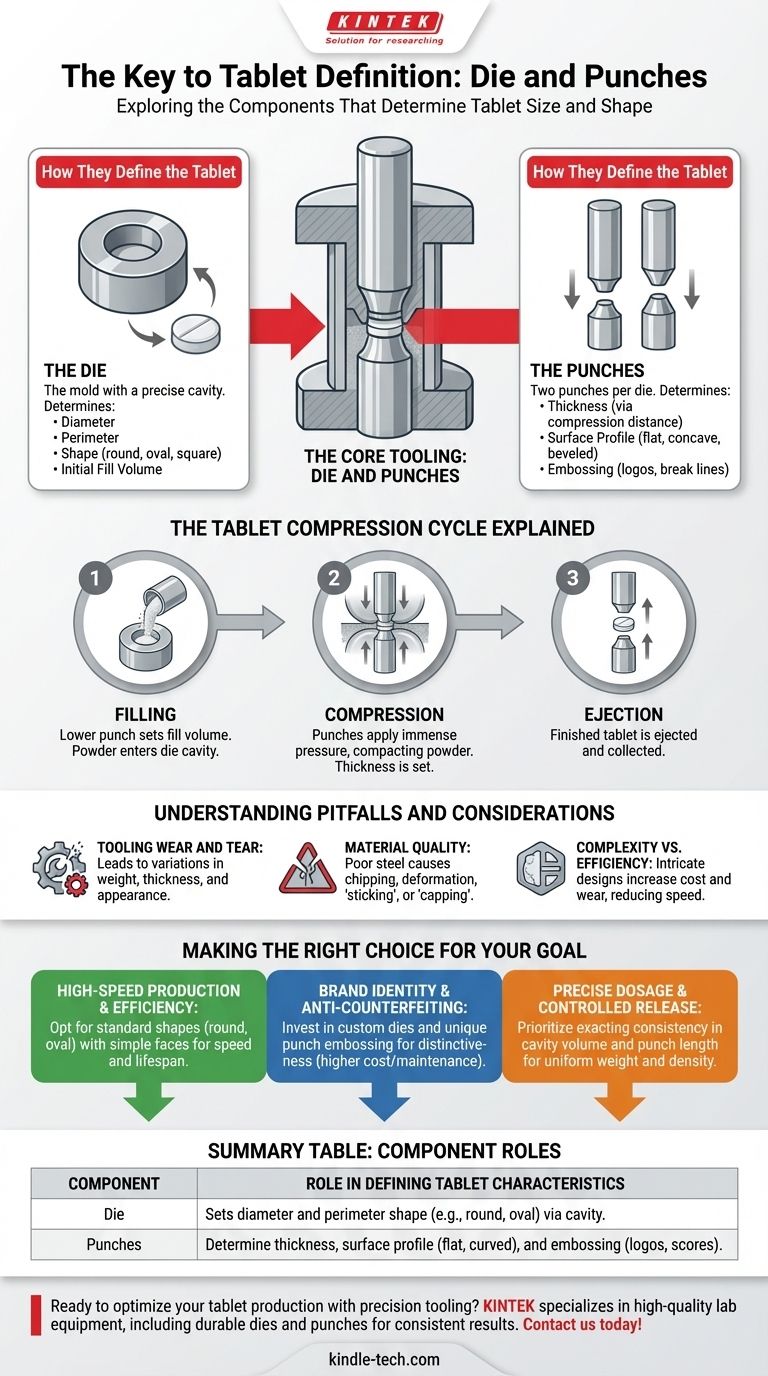

The size and shape of a tablet are fundamentally defined by two components: the die and the punches. These parts form a precision mold where granulated powder is compressed. The die's internal cavity dictates the tablet's diameter and perimeter shape, while the faces of the upper and lower punches form its top and bottom surfaces and determine its final thickness.

The core principle is simple: the die acts as the mold that sets the tablet's shape and diameter, while the punches compress the powder within that mold, defining the tablet's thickness and surface features. This set of components is collectively known as the "tooling."

The Core Tooling: Die and Punches

To understand tablet manufacturing, you must first understand the precise interplay between the die and the punches. This tooling is the heart of any tablet press.

The Role of the Die

The die is a hardened steel component with a precisely machined hole, or cavity, running through its center.

This cavity is the primary determinant of the tablet's shape (e.g., round, oval, square) and its diameter. The powder fills this cavity before compression begins.

The Role of the Punches

For every die, there is a corresponding set of two punches: an upper punch and a lower punch.

The punch tips are the surfaces that make direct contact with the powder. Their contour determines the final profile of the tablet's faces—whether they are flat, curved (concave/convex), or beveled.

Furthermore, any logos, break lines (scoring), or identifying marks are engraved directly onto the punch tips.

How They Define Size and Weight

The process begins when the lower punch descends within the die, creating a space for the powder to fill. The volume of this fill is precisely controlled.

The upper punch then enters the die from above. As the punches converge under immense pressure, they compress the powder, binding the particles together.

The final tablet thickness is determined by the closest distance the two punch faces come to each other at the point of maximum compression. This, along with density, dictates the tablet's final weight.

The Tablet Compression Cycle Explained

These components work together in a rapid, cyclical process to produce tablets of uniform size, shape, and weight.

Step 1: Filling

The feeder system deposits powder into the die cavity. The position of the lower punch at this stage sets the volume of powder, which is a critical factor for dosage control.

Step 2: Compression

The upper punch lowers into the die, sealing the powder within the cavity. Both punches then move together, typically between large pressure rollers, which apply the force needed to compact the powder into a solid tablet.

Step 3: Ejection

After compression, the upper punch retracts out of the die. The lower punch then rises, pushing the finished tablet up and out of the die cavity, where it is swept away for collection.

Understanding the Pitfalls and Considerations

While the concept is straightforward, the quality and maintenance of the tooling are critical for successful production.

Tooling Wear and Tear

Punches and dies are subjected to extreme pressure and abrasive friction. Over time, they will wear down, which can lead to variations in tablet weight, thickness, and appearance.

Material Quality

The steel used for tooling must be robust enough to withstand compression forces without chipping or deforming. Poor quality tooling leads to production defects like "sticking" (powder adhering to the punch face) or "capping" (tablet splitting).

Complexity vs. Efficiency

Highly complex tablet shapes or deep logos require more intricate and expensive tooling. These custom designs can be more challenging to manufacture and may be more prone to wear and operational issues than simple round or oval shapes.

Making the Right Choice for Your Goal

The design of your tablet tooling should directly support your primary objective.

- If your primary focus is high-speed production and efficiency: Opt for standard shapes like round or oval with simple punch faces to maximize manufacturing speed and tooling lifespan.

- If your primary focus is brand identity and anti-counterfeiting: Invest in custom-shaped dies and punches with unique logos or embossing, understanding the higher cost and maintenance requirements.

- If your primary focus is precise dosage and controlled release: Prioritize exacting consistency in die cavity volume and punch length to ensure uniform tablet weight and density, which are critical for pharmacological performance.

Ultimately, mastering the relationship between the die and punches is the key to controlling tablet quality, uniformity, and efficacy.

Summary Table:

| Component | Role in Defining Tablet Characteristics |

|---|---|

| Die | Sets the tablet's diameter and perimeter shape (e.g., round, oval) via its cavity. |

| Punches | Determine tablet thickness, surface profile (flat, curved), and embossing (logos, scores). |

Ready to optimize your tablet production with precision tooling? KINTEK specializes in high-quality lab equipment and consumables, including durable dies and punches designed for consistent tablet size, shape, and dosage control. Whether you need standard tooling for efficiency or custom designs for brand identity, our solutions ensure uniformity and reliability. Contact us today to discuss your tablet press needs!

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- Which type of tablet press is more suitable for large scale production? Rotary Presses for High-Volume Efficiency

- What is the purpose of the pelletizing machine? Transform Waste into Valuable, Dense Pellets

- What size are pellet mill die sizes? Master the L/D Ratio for Perfect Pellets

- What is the difference between single punch and rotary tablet press? Choose the Right Machine for Your Lab or Production

- What is the process of pelleting biomass? Transform Raw Biomass into High-Value, Energy-Dense Fuel

- What is the function of a tablet press? Transforming Powder into Precise, Uniform Tablets

- What is a punch tablet press? Precision Tableting for R&D and Small Batches

- What are pill presses used for? Transforming Powders into Precise Tablets for Medicine, Supplements, and More