In short, a coating on a carbide tool primarily increases its wear resistance, heat resistance, and lubricity. These enhancements are not minor tweaks; they fundamentally change how the tool behaves under pressure. This allows the tool to cut faster, last significantly longer, and often produce a better surface finish on the workpiece.

A coating acts as a high-performance, sacrificial shield for the carbide tool. This barrier is engineered to be harder, slicker, and more thermally stable than the carbide itself, protecting the sharp cutting edge from the intense heat and abrasion of the machining process.

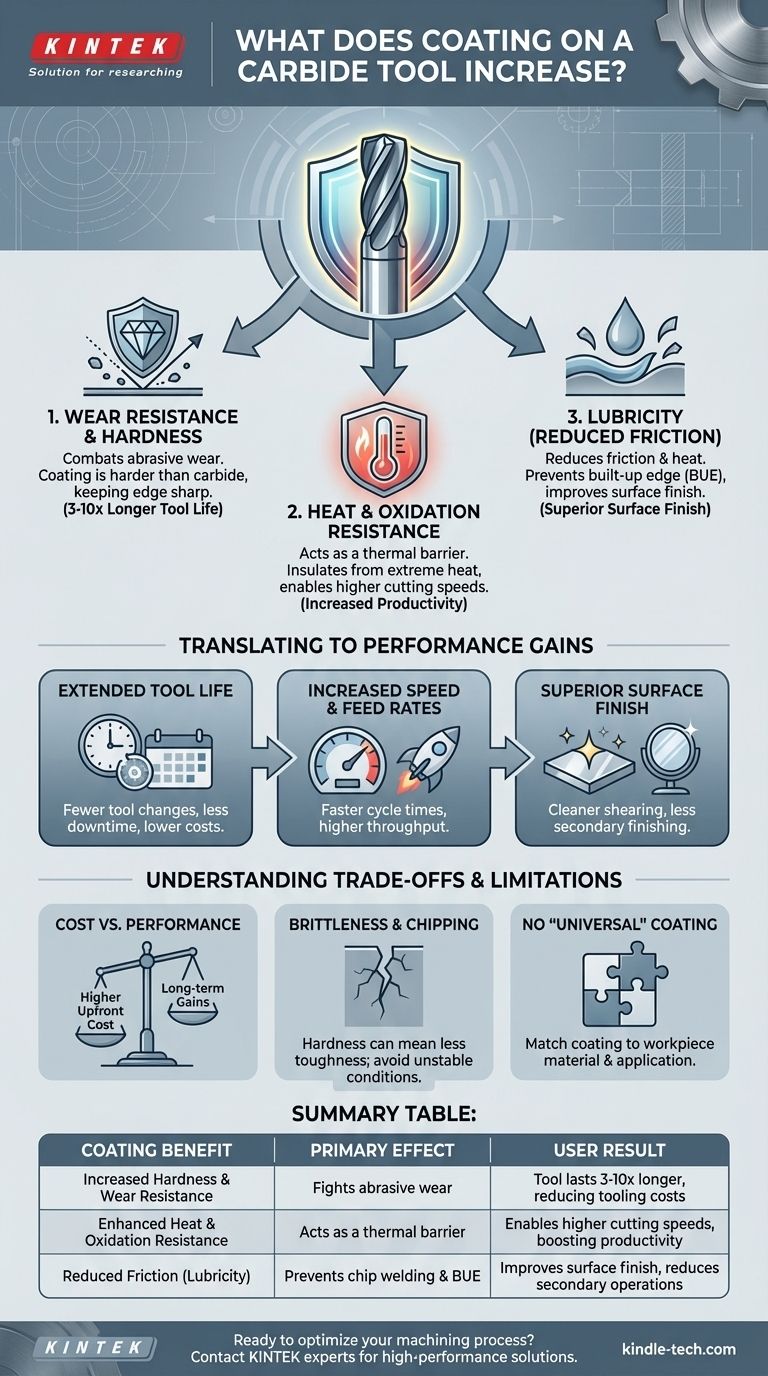

The Core Functions of a Tool Coating

A tool coating is a micro-thin layer of advanced material, often only a few microns thick, that is bonded to the surface of the carbide. While the carbide provides the tough, rigid backbone, the coating provides the frontline defense.

Enhancing Hardness and Wear Resistance

The most fundamental benefit of a coating is a dramatic increase in surface hardness. Many modern PVD (Physical Vapor Deposition) or CVD (Chemical Vapor Deposition) coatings are significantly harder than the underlying carbide substrate.

This superior hardness directly combats abrasive wear. As the tool cuts through material, microscopic hard particles in the workpiece act like sandpaper, dulling the cutting edge. The coating resists this abrasion, keeping the edge sharp for a much longer period.

Managing Heat and Oxidation

Cutting metal generates immense, localized heat—often enough to make the cutting zone glow red. This heat is the enemy of a sharp edge, as it can soften the carbide binder material (cobalt) and cause the tool to deform and fail rapidly.

Coatings act as a thermal barrier, insulating the carbide from the extreme temperatures in the cut. Furthermore, they provide oxidation resistance, preventing the tool material from chemically degrading at high temperatures. This thermal stability is what enables the use of much higher cutting speeds.

Reducing Friction (Increasing Lubricity)

Many coatings have a very low coefficient of friction, making them far "slicker" than uncoated carbide. This lubricity has two critical effects.

First, it reduces the amount of heat generated from friction between the tool and the workpiece. Second, it helps chips flow smoothly and evacuate the cutting zone, preventing a common failure mode known as built-up edge (BUE), where workpiece material welds itself to the tool.

Translating Coating Properties into Performance Gains

Understanding the functions of a coating is useful, but its true value lies in how these properties translate to tangible results on the shop floor.

The Impact on Tool Life

By protecting the cutting edge from abrasion and heat, a coating drastically extends the operational life of a tool. A coated tool can often last anywhere from 3 to 10 times longer than its uncoated counterpart in the same application. This means fewer tool changes, less machine downtime, and lower overall tooling costs.

The Impact on Speed and Feed Rates

Because a coated tool can withstand much higher temperatures, an operator can significantly increase the cutting speeds and feeds. Running a machine faster directly reduces the cycle time for each part, dramatically increasing productivity and throughput without requiring new machinery.

The Impact on Surface Finish

The improved lubricity and prevention of built-up edge result in a cleaner shearing action. This often produces a superior surface finish on the part, which can reduce or even eliminate the need for secondary finishing operations like grinding or polishing.

Understanding the Trade-offs

While the benefits are significant, a coating is not a magic bullet. An objective analysis requires understanding its limitations.

Cost vs. Performance

Coated tools have a higher upfront cost than uncoated tools. The decision to use them is an economic calculation: will the gains in tool life and productivity offset the higher initial price? For most production environments, the answer is a definitive yes.

Coating Brittleness and Edge Chipping

Hardness often comes with a trade-off in toughness. Some ultra-hard coatings can be more brittle than the carbide substrate. In unstable machining conditions with heavy vibration, chatter, or interrupted cuts, this can lead to microscopic chipping of the coating, which can accelerate tool failure.

The Myth of the "Universal" Coating

There is no single coating that is best for every application. A coating optimized for cutting hardened steel (like AlTiN) will perform poorly in aluminum, where a slicker, more lubricious coating (like TiB2 or DLC) is needed to prevent material from sticking. Matching the coating to the workpiece material and application is critical.

Making the Right Choice for Your Goal

Ultimately, the choice to use a coated tool depends on your specific objective.

- If your primary focus is maximizing tool life and reducing tooling costs: A coated tool is almost always the superior choice, as the extended life and reduced machine downtime will far outweigh the initial investment.

- If your primary focus is maximizing productivity and reducing cycle times: High-performance coatings are essential, as they are the enabling technology that allows for the higher speeds and feeds required for high-efficiency machining.

- If you are machining soft, non-ferrous materials (like aluminum): Use either a highly polished uncoated tool or a specialized coating with extreme lubricity (like DLC) to prevent chip welding.

- If you are working with a low-horsepower machine or an unstable setup: A very sharp, uncoated tool might perform more reliably, as it exerts less cutting pressure and avoids the risk of a brittle coating chipping.

Understanding the role of a coating transforms it from a simple feature into a strategic tool for optimizing your entire machining process.

Summary Table:

| Coating Benefit | Primary Effect | Result for the User |

|---|---|---|

| Increased Hardness & Wear Resistance | Fights abrasive wear | Tool lasts 3-10x longer, reducing tooling costs |

| Enhanced Heat & Oxidation Resistance | Acts as a thermal barrier | Enables higher cutting speeds, boosting productivity |

| Reduced Friction (Lubricity) | Prevents chip welding and built-up edge | Improves surface finish, reduces secondary operations |

Ready to optimize your machining process with the right tool coating?

At KINTEK, we specialize in providing high-performance lab equipment and consumables, including solutions for advanced tool coating analysis and development. Whether you're in R&D or production, our expertise can help you select the ideal coating to maximize tool life, increase speeds, and achieve superior surface finishes.

Contact our experts today to discuss how we can support your laboratory and manufacturing needs!

Visual Guide

Related Products

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Custom CVD Diamond Coating for Lab Applications

People Also Ask

- What are thin films in electronics? The Microscopic Layers Powering Modern Devices

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- What are the different types of thin film deposition? A Guide to PVD vs. CVD for Your Lab

- Why RF sputtering is better than DC sputtering? The Ultimate Guide to Material Deposition

- What are the methods of thin film application? A Guide to Chemical and Physical Deposition

- What is thin film process technology? Unlock New Material Properties for Your Products

- What are the advantages of sputtering deposition? Achieve Superior Thin Films for Demanding Applications

- What is deposition techniques? A Guide to PVD vs. CVD for Thin-Film Applications