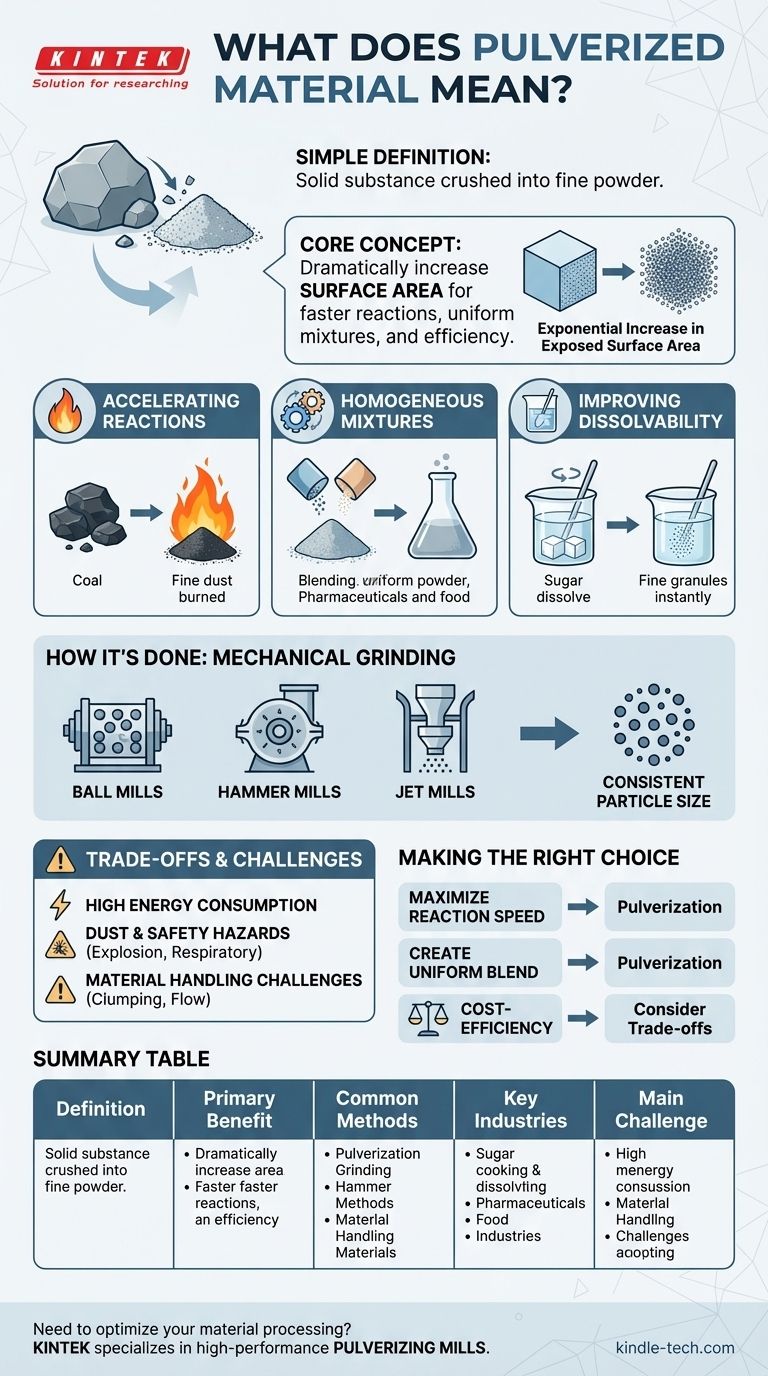

In simple terms, a pulverized material is any solid substance that has been crushed, ground, or otherwise broken down into a fine powder or dust. This process fundamentally changes the material's physical properties, reducing it to a collection of tiny particles, much like turning a solid rock into fine sand or flour.

The core concept to understand is that pulverization isn't just about making something smaller. It's a strategic process to dramatically increase a material's surface area, which unlocks faster chemical reactions, more uniform mixtures, and greater processing efficiency.

The Core Principle: Why Surface Area Matters

Pulverizing a material transforms its behavior. A solid cube has six sides, but when you pulverize it into a million tiny particles, you expose the interior of that cube, creating millions of new surfaces. This exponential increase in exposed surface area is the primary goal.

Accelerating Chemical Reactions

Many chemical reactions, including combustion, only occur at the surface of a material.

By pulverizing a substance like coal, you expose vastly more surface area to oxygen, allowing it to burn almost as quickly and completely as a gas. This is the principle behind most modern coal-fired power plants.

Ensuring Homogeneous Mixtures

Achieving a perfectly uniform mixture of several solid ingredients is nearly impossible when they are in large, irregular forms.

Pulverizing each component into a fine, consistent powder allows them to be blended together evenly. This is critical in industries like pharmaceuticals, where precise dosages are required, and in food production for consistent flavor and texture.

Improving Dissolvability

A solid material dissolves in a liquid at its surface.

By increasing the surface area through pulverization, you allow the liquid to access more of the material at once, causing it to dissolve much faster. This is why granulated sugar dissolves more quickly than a sugar cube.

How Materials Are Pulverized

The process of pulverization is more than just smashing. It's a controlled engineering process designed to achieve a specific particle size distribution.

Mechanical Grinding and Crushing

The most common methods involve mechanical force. Industrial equipment like ball mills, hammer mills, and jet mills are used to crush, impact, and abrade materials until the desired fineness is achieved.

The Goal: Consistent Particle Size

The objective is to produce a powder where the particles are not only small but also relatively uniform in size. This consistency ensures predictable behavior, whether it's for burning, mixing, or dissolving.

Understanding the Trade-offs

While powerful, pulverization is not without its challenges and costs. It's an industrial process that requires careful consideration of its downsides.

High Energy Consumption

Crushing and grinding solid materials is an extremely energy-intensive process. The energy required to run industrial-scale mills can be a significant operational cost.

Dust and Safety Hazards

Fine powders present two major risks. First, airborne dust can be a serious respiratory hazard if inhaled. Second, for combustible materials like coal, flour, or certain metals, a dense cloud of dust can be highly explosive if exposed to an ignition source.

Material Handling Challenges

Fine powders can be more difficult to handle, store, and transport than their solid-state counterparts. They can clump together with moisture, and ensuring consistent flow out of silos and hoppers can be an engineering challenge.

Making the Right Choice for Your Goal

Deciding whether to pulverize a material depends entirely on the desired outcome.

- If your primary focus is maximizing reaction speed (e.g., combustion or chemical processing): Pulverization is often a non-negotiable step to create the necessary surface area for an efficient reaction.

- If your primary focus is creating a uniform product blend: Pulverizing the components is the most reliable method for achieving true homogeneity in a solid-state mixture.

- If your primary focus is cost-efficiency: You must carefully balance the performance benefits of a pulverized material against the significant energy, safety, and handling costs associated with producing it.

Ultimately, pulverization is a fundamental tool used to manipulate the physical form of a material to achieve a specific and powerful chemical or industrial result.

Summary Table:

| Key Aspect | What It Means |

|---|---|

| Definition | A solid substance crushed into a fine powder to increase its surface area. |

| Primary Benefit | Dramatically accelerates chemical reactions and enables perfectly uniform mixtures. |

| Common Methods | Ball mills, hammer mills, and jet mills are used for controlled grinding. |

| Key Industries | Pharmaceuticals, food production, energy (coal), and chemical processing. |

| Main Challenge | High energy consumption and potential safety hazards from combustible dust. |

Need to optimize your material processing? KINTEK specializes in high-performance lab equipment, including pulverizing mills, to help you achieve the perfect particle size for faster reactions and homogeneous blends. Contact our experts today to find the right solution for your laboratory's specific needs!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- Why is a laboratory ball mill used in Co-Ni catalyst research? Optimize CO2 Conversion with Precise Milling

- How does a high-energy planetary ball mill facilitate the synthesis of sulfide glassy electrolytes? Achieve Amorphization

- What is the function of ball milling equipment in NZSSP electrolyte preparation? Optimize NASICON Solid-State Synthesis

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding

- What are the disadvantages of a ball mill? High Energy Use, Noise, and Contamination Risks